‘Large Square Baler Mode’ is a new software upgrade available for latest T7 LWB and T7 HD tractors with Horizon Ultra cabs and PLM Intelligence controls. Mode activation is through the Intelliview 12 touchscreen terminal, on the tractor settings display page.

The mode is compatible with all New Holland BigBalers produced since 2018 carrying the latest software updates.

How does ‘Large Square Baler Mode’ work?

When a New Holland BigBaler is linked through Isobus to the PLM-equipped New Holland tractor, the large baler mode software monitors the baling action to predict when each plunger stroke will occur. Additional fuel is injected to meet the momentary demand for extra power, just as the ram strikes the bale. This reduces engine speed variation and means that the PTO and baler transmission speed also remain more consistent.

The Terraglide hydraulic front axle suspension is also utilised by the system, and the cushioning action is stiffened momentarily to further reduce the nodding effect in time with each plunger compression stroke.

Is it effective?

Because Large Square Baler Mode is activated and deactivated by just a touch on the terminal, it is possible to compare operation with and without it on the move, while all other working parameters remain the same. Farmers Guide tried one of the latest T7 HD tractors with a New Holland BigBaler 1290HD, baling weathered barley straw on a large farm in Essex.

With Large Square Baler Mode engaged, the tractor stationary and the baler running at its standard 1,500rpm there was very little nodding movement, but as soon as the mode was switched off, the rocking motion increased.

Baling the swath, the same comparison produced similar results – when the mode was activated, the nodding motion reduced and the ride became more comfortable.

Large Square Baler Mode is activated through the Intelliview 12 touchscreen.

Operating characteristics

Interestingly, it takes a few seconds for the engine management system to ‘learn’ the plunger timing each time the mode is engaged, so the effect is gradual at first with full synchronisation after 10–15 seconds.

Apart from the reduced rocking motion, a change to the exhaust note is another indicator that large baler mode is selected. This is because the engine droop characteristics are adjusted, and revs are kept within tighter parameters. To achieve this; extra fuel is injected at precisely the right moment; a fraction of a second before the working load peaks as the plunger meets the bale – matching the power produced to the demand and reducing engine speed fluctuations.

Without baler mode, the engine management system works retrospectively to restore the engine speed to its pre-set value after it has been pulled down by the extra load, then extra fuel is injected to restore the revs.

We monitored noise levels inside the cab while switching between baler mode engaged and disengaged. The difference in exhaust tone is easy to detect, and the sound meter indicated noise levels approximately 1dB less with baler mode activated, although the working speed and straw volume remained constant.

New Holland claims that significant fuel savings are achieved by activating baler mode – as the tractor and baler operating speed remains more constant.

Experienced user view

The T7 HD tractor tested by Farmers Guide was a demonstrator on loan to Essex-based, Blackwater Baling. Owned and managed by Gavin Strathern and his wife Liz, Blackwater Baling operates as a grass and straw baling contractor and bale supplier. The contracting service cuts, prepares and bales hay, haylage and straw for customers from private horse owners to larger professional breeding and racing stables.

Straw baling is offered as a contracting service although a large amount is also bought in the swath and baled behind the combine, then transported and stored for supply throughout the year to farms in the East of England plus a growing number in the South-West. He also supplies bales as biomass for straw burning power stations.

Experienced operator, John Baker said the mode makes a big difference to ride comfort. He also believes that it increases productivity and reduces operator fatigue, while also allowing him to drink cups of tea on the move without risking spillages caused by the baler’s characteristic rocking motion.

New Holland fleet

The company’s fleet includes eight New Holland large balers. An RB180 makes round silage hay, haylage and straw bales mainly for livestock use. Seven large square balers include BB920, BB1270, BB1290 BB9090 models, plus two recently acquired 1290HD machines selected to produce extra dense bales for biomass. The balers and Transtacker bale chasers operate behind a fleet of tractors, most of which are New Holland T7 machines.

“New Holland machinery supplied by our local dealer, Ernest Doe, makes up the core of our tractor and baler fleet,” explained Gavin. “There is no single reason for that – it’s because of the whole package including the machines and the way they are backed-up by the dealer and the manufacturer. The New Holland T7 tractors are bombproof, and we find them far more reliable than competitor brands. We own models from the T7.210 to the T7.270 currently, and hire two additional tractors through the grass and straw harvesting season.”

Up to 14 machinery operators are employed during the harvesting season which starts with first-cut haylage and concludes in the autumn when the last of the straw has been baled.

“We decided early on to specialise in baling and bale supply,” continued Gavin. “By specialising we can offer the most efficient service without being distracted by other tasks. We also offer grassland fertilising and spraying as well as pasture reseeding, which complements our grass harvesting service and is for the same customers.”

Added comfort, convenience and safety

Operator John Baker has extensive experience operating New Holland T7 tractors and balers, having worked for Blackwater Baling for the past five years. He spent a week driving the demonstration T7 HD tractor as well as a new T7.300 LWB model, both with Big Baler Mode, working with the company’s newest 1290HD large square baler. “It significantly improves comfort,” he said, “and it’s much easier to drink or eat while baling without risking spillages caused by the baler’s rocking motion. Using the touch screens and a smartphone is easier too. The effect is even more pronounced for a passenger, without the pneumatic suspension that benefits the driver.”

John said that the benefit of baler mode is especially noticeable when simultaneously baling downhill and turning. “Often, on steeper slopes it can feel as if a baler is pushing the back end of the tractor into a jack-knife with each plunger stroke, especially during tight turns. With the baler mode selected, that pushing action is reduced. The whole operation feels much more comfortable and controlled.”

New Holland tractor product manager David Redman (left) is pictured beside Blackwater Baling managing director Gavin Strathern and baler operator John Baker.

Extra capabilities

Gavin said that all the operators who tried the two tractors with the baler mode were impressed. “We have a superb team of full- and regular part-time operators who work long days during harvest, and we rely on them to provide a great service for our customers. Their feedback regarding the latest T7.300 and the T7 HD tractor with the new cabs, and the enhanced comfort due to the Large Square Baler Mode software is extremely positive, and I am quite sure that when we next update the tractors, then it will be for models with extra power and the baler mode software unlocked.”

The verdict

Large Square Baler Mode is surprisingly effective. The constant ‘nodding’ movement associated with operating all large square balers is something operators accept as part of the job. However, by selecting a New Holland T7 HD or T7 LWB tractor with PLM controls to work with a compatible New Holland large square baler, this rocking action can be reduced improving operator comfort and reducing fatigue, with no reduction in baling rate or performance.

“I believe that because it manages engine performance so tightly to suit the baler, it actually increases the work rate while also reducing fuel consumption,” concluded John. “It’s worth having and I will request it next time my current T7.270 is due for updating.

“Just being able to drink cups of tea without having to stop on a headland or fight the rocking motion makes such a difference to a long working day.”

Mzuri’s new Pro-Til iGen one-pass drill

Farmers Guide attended an exclusive preview and demonstration of Mzuri’s new Pro-Til iGen one-pass drill on the manufacturer’s farm ahead of the new model’s official Cereals debut. David Williams saw it in action

The new drill fills a gap in Mzuri’s drill line-up, satisfying demand for a cost-effective, high-output direct drill with a 4.8m working width. “It’s a new approach for Mzuri,” managing director Martin Lole told Farmers Guide. “Like our other drills, it’s designed to produce a perfect seeding environment working straight into stubbles, cover crops and grassland. It is our only linkage-mounted model, but retains our proven seeding technique, producing a tilth, reconstructing the seeding zone and then placing and covering the seed. We firmly believe that this is the right approach to give crops the best start.”

Farmers Guide saw the new Mzuri Pro-Til iGen 4.8m mounted drill at work in Worcestershire.

Wider appeal

Mzuri’s existing Pro-Til and iPass drills are all trailed, but Martin said that although drawbar drills do a better job of maintaining a constant drilling depth over undulating ground and reduce compaction on headlands, they cost considerably more than linkage-mounted drills which means that the price is often too high for smaller farms to justify. As well as a lower purchase price, advantages of mounted models include easier manoeuvring on headlands and around obstructions and more convenient travel on narrow roads, but disadvantages include reduced seed and fertiliser capacity due to weight limitations.

Increased demand

“We didn’t offer a 4.8m mounted drill previously, but requests from customers for a drill of that type and size were increasing as smaller arable and mixed farms want to reduce their crop establishment costs by reducing the amount of tillage,” stressed Martin.

“The 4.8m width is a good compromise. It’s easy to pull but can achieve high work rates, and only five bouts are needed for the headlands. However, we will almost certainly add 3.0, 4.0 and 6m versions in future to benefit more sizes and types of farms.”

The 4.8m drill is the first mounted model available from Mzuri but incorporates proven design features from trailed drills in the range.

Individual coulters

The new drill has 15 coulters giving 320mm row spacing. Key features from other drills in the range have been incorporated, including leading tines which prepare a nursery seedbed ahead of the coulters, targeted reconsolidation of the seeding zone by a full-width packer roller with a ridge profile to ensure consolidation pressure is applied exactly where it is needed – behind the leading tines, and individually mounted seed coulters for optimum ground contour following and consistent seeding depth.

Each coulter is on a separate spring, attached through a parallelogram linkage to the full-width packer. Press wheels at the rear of each coulter assembly control the seeding depth, and operating pressure is adjusted through the packer roller frame. Pivoting the coulter assembly towards the rear increases pressure on the press and depth control wheel as well as the rear harrow, but a constant seeding depth is maintained. Pressure control is simple – using ram spacers to limit travel.

A double row of z-harrow tines at the rear covers the seed and leaves a level finish.

Accurate at high rates

There is currently no combined seed and fertiliser hopper option as Martin said keeping the operating weight low is a priority, but there is potential to develop a two-section hopper in future for simultaneous seed and fertiliser placement.

The 2,200-litre tank is pressurised and supplies accurately metered seed at up to twice the rate of conventional systems. Twin metering units supply the coulters through a single seed distribution head. The pressurised hopper and twin meters ensure a consistent supply through the 15 coulters even at speeds up to 18kph – which proved successful during trials. “The drill is easy to pull, especially with low-disturbance leading tines and our 240hp tractor had plenty of power and traction. It’s designed to achieve high work rates and at 18kph the finish and results were excellent. If other types of leading tine were fitted then a bigger tractor with more power would be needed to achieve similar speeds, especially when conditions are tougher,” continued Martin.

The front leading legs have low-disturbance points and working depth is controlled by the relative position of the tines and the full-width roller.

Superior concept

Martin describes himself as a big believer in the front leg leading tine concept. “They are so much more successful than leading discs in a wide variety of conditions.

“We usually recommend setting the tines to work just 20–30mm below the following seeding coulters to create a tilth at seed depth and allow roots to flourish as crops develop. However, they can work much deeper if extra soil loosening is needed. The drill is strongly made and capable of handling the increased stresses behind high horsepower tracked tractors without any problems,” Martin added.

Early availability limited

Limited numbers of the new drills will be available this autumn, but full production will commence in time for spring drilling next year. Rumours regarding the new drill’s availability have been circulating for some time, and Martin said he has already received many enquiries from potential customers. These include current users of competitor 4.8m drills who have recognised advantages of the Mzuri seeding concept, as well as many already using Mzuri Pro-Til and iPass models.

The seed hopper is pressurised. A convenient manual locking system secures the lid.

Strategy works

“Much of our farm is heavy Evesham Lias clay and since adopting a direct-drilling crop establishment regime, our fields have improved and charlock and black-grass populations which were both high when we arrived have declined. Black-grass doesn’t thrive in well-structured soils and the wider row spacing we favour gives a great opportunity for herbicides to achieve maximum efficacy and reduce the small number of plants that remain. We do everything we can to increase organic matter in the soils, and the more chopped straw remains on the surface after harvest, then the more the worms will pull down. We bring in sheep for mob grazing and our organic matter contents continue to increase. Surveys have demonstrated that the amount of nitrate from our field drains is insignificant, and we rarely apply insecticides or fungicides now as the crop health is so good. Our system works well and saves time and costs.

“The new iGen drill will be priced up to 30% less than equivalent trailed machines allowing even more growers to benefit from advantages of our crop establishment system,” Martin concluded.

Demonstrator view

Luke Vallis works on the farm and is also the company’s product demonstrator. “I recently joined Mzuri and had used zero-til and direct-drills on farms previously,” he said. “I am extremely impressed by the iGen. It’s very easy to use and minimal set-up is required. Moving between fields where the soil types vary, most of the time I can just unfold the drill and start working and achieve great results.”

Shop used seed drills for sale on FarmAds.

A new option for farmers and contractors needing a high output direct tine drill is available from Virkar. Farmers Guide’s David Williams visited Samagri Ltd, the manufacturer’s UK importer, to see it at work.

Virkar direct drills have been manufactured in Spain since 2010 and are imported to the UK by Hampshire-based Samagri, which took on the brand in 2018 to complement its existing Kockerling machinery range. “The Kockerling line-up doesn’t include dedicated direct drills, so adding Virkar has allowed us to provide a solution for the growing number of farmers looking for drills capable of establishing crops into both cultivated and undisturbed soils,” explained Samagri sales manager, Nigel Long.

Coulter options

Virkar’s drill range includes Dynamic models in working widths from 4.5–7.0m, and larger Ocean models which are available with working widths up to 8.0m currently, but from September this year there will be versions up to 15.0m wide. This is the first time that tine-only coulters have been available from Virkar, and the new option can be specified for all drills right up to the widest 15.0m.

“Of the drills sold in the UK since we took on the brand three years ago, 24 have been Dynamic DC (disc and coulter) models – with a leading disc to cut through trash and create a slot ahead of the seeding tine which is followed by two closing press wheels,” explained Nigel. “There has also been demand for the Dynamic D (disc) version with a simple single disc coulter, and we also offer a (DD) double-disc coulter version which features a Turbo disc in front of the disc coulter to cut through residues and prevent hair-pinning.”

All models have up to 35cm of vertical coulter travel, with even seeding depth across the width ensured by a pressure accumulator. The coulters bolt directly to the main frame, rather than relying on separate brackets and Nigel explained that this ensures maximum strength and performance. The complete central section of the drill including the chassis, hopper and frame are identical whatever type of coulter is specified, so it is possible to change the coulter type during the season, or as the transition to zero-tillage progresses.

The rear steering axle helps maintain constant seed row spacing during turns and on cross slopes. It also allows the 6m drill to make consecutive passes with headlands of only 12m.

Affordable and versatile

“Although the DC leading disc and tine coulters have been most popular so far, buying the drill with the new tine-only option provides considerable cost savings. For those not drilling into high trash volumes or cover crops, then the simpler tine-only design is a cost-effective solution,” he continued. “It offers the same precise depth control which for many growers is a priority, and the coulters are staggered for the widest possible spacing to ensure trash and large stones flow through easily without creating blockages.”

Easy conversion

The coulters are divided between four rows, and 19 or 25cm row spacing is available – even on the widest versions. The modular construction allows the working width to be easily altered by bolting on or removing sections. The main frame is pre-drilled which makes it possible to convert the drills from 19 to 25cm spacing to suit different crops during the season. In addition, alternate rows can be shut off to achieve double row spacing.

Coulter pressures up to 280kg ensure reliable ground penetration and depth control. Pressure is adjusted from the cab, and Samagri director Sam Berry said that this allows users to optimise the drill’s performance and ensure consistent seeding depth as soil types and conditions vary between fields, or within the same field. Control is through an Isobus link, and possible future developments include the ability to automatically adjust the pressure according to field maps and the GPS location, reducing the operator’s workload.

A pair of wheels with a slight stagger follow the tine coulter and close the slot, ensuring seed to soil contact.

Improved accuracy and manoeuvrability

Large rear transport wheels have active steering, controlled by a potentiometer on the drawbar. The steering compensates during turns to keep the seed rows at the correct spacing, and it can also be controlled by the operator to compensate for slip when working on cross-slopes. Control by GPS is an option. “The steering angle is very small, but it makes a surprising difference to the drill’s performance,” suggested Nigel. “It also allows return working bouts, even on small headlands.”

The 5,000-litre drill hopper can be divided into three sections, split longways to maintain even weight distribution. Three Accord-type metering units are used on the Dynamic drills. The flow from all three units is combined and delivered through a single tube to each coulter, avoiding the need for wider working elements which would move more soil. Virkar’s own metering system is fitted to Ocean versions, which have larger 10,000-litre capacity hoppers capable of being divided into four sections.

There are four rows of coulters with 19mm or 25mm row spacing. The coulters have up to 35cm vertical travel. The working pressure across all the coulters is linked through a single circuit with an accumulator, allowing convenient adjustment from the cab.

Tine advantage

“We are very pleased to have the new tine coulter drill which will allow us to provide solutions for even more farmers and contractors,” said Sam. “On hard, clay soils and stony ground, then tine drills perform better than disc drills, and the tines will perform better in wet, sticky conditions too. Also, being less expensive than a disc, or disc and tine drill, it’s a more affordable option for those just starting the transition to direct drilling.”

The staggered, open tine arrangement is popular with operators as it is easy to monitor all the coulters from the cab, and very resistant to blocking.

Saving costs, improving soils

“It’s been noticeable that more farmers are considering the move to direct-drilling regimes for a host of reasons; from reducing establishment costs and saving time, to improving soil health. Many have managed a gradual transition from full inversion tillage to min-till regimes and then direct-drilling, and others just moved straight to direct-drilling.

“Some of our own farm is direct-drilled and the rest was pre-cultivated, but this spring’s weather highlighted that on our Hampshire flint and clay soils, the direct-drilled land recovers much more quickly after wet weather, which increases opportunities to get on the fields to apply fertilisers and crop treatments in a timely manner.”

Attractive features

In Spain, Virkar drills are the most popular choice for direct-drilling, and the UK has become the brand’s number one export market. Nigel isn’t surprised. “It’s a rugged and well-designed drill, with attractive features,” he stressed. “The amount of coulter travel is exceptional and whether ground undulations are across or along the drill, they can adapt to maintain consistent seeding depth. Achieving even establishment is key to effective crop management throughout the season, and when potential customers see the drills working the benefits of the design are immediately obvious.

“The coulters are rugged and create very little soil disturbance. The amount of stagger between the four rows allows plenty of space for trash, and if the crop establishment system evolves or changes then the coulter type can be easily changed. The drill can also accommodate a rear three-point linkage, allowing implements such as spreaders, harrows or a roller to be attached.”

Sam commented that several farms near the Samagri Hampshire base have invested in Virkar drills recently. “I think that because we farm on soils that can be quite challenging, customers from all over the UK can tell that we understand their farming challenges and trust us to recommend appropriate solutions. We use both a Kockerling drill and a Virkar on our own farm and both systems work well. It has been interesting that since we took on the Virkar range, many growers in the local area have seen our crops, looked at the drills and then invested.”

Sam Berry (right) with Nigel Long.

Attractive pricing

The new Dynamic C tine drill is available now to order, and the larger Ocean C version will be available from September. Prices for a Virkar Dynamic C 6m drill with 25cm coulter spacings start from approximately £90K, the DC leading disc and tine coulter version costs from £110K and the D disc, and DD double-disc models are from approximately £120K.

Browse second-hand drills for sale at FarmAds.

As demand for higher capacity combines continues to grow, sales of trailers capable of transporting the wider and heavier headers are also increasing. One company which has seen a big rise in demand is Abrey Agricultural. Farmers Guide‘s David Williams reports.

Based near Saffron Walden in Essex, Abrey Agricultural is the official UK importer for Ziegler products. The German manufacturer offers a range of high-quality header trailers and specialist combine headers – including versions for oilseed rape, sunflower and maize harvesting. The header trailer line-up includes single-axle models suitable for headers up to 7.7m working width and weighing up to 3.6t. Close-coupled, tandem-axle trailers can carry headers up to 9.5m and weighing up to 3.6t, and double-axle trailers with a steering front axle and a fixed rear axle will accommodate headers up to 10.7m and weighing up to 6t.

Exceptional manoeuvrability

While UK sales of all the trailers are increasing, the Abrey team has experienced a significant rise in the numbers of enquiries and sales of its flagship Four Wheel Turn (4WT) trailers. These transport headers up to 12.5m and with weights up to 6t or 7.2t depending on their construction, but the biggest attraction for users is their ability to accurately follow the same line as the tractor wheels when manoeuvring, making it easy to turn into tight field gateways from narrow lanes – typical on many UK farms.

Premium products

Abrey Agricultural managing director, Toby Abrey commented that he feels fortunate to have such a great range of products to offer, and highlighted features which make the 4WT trailers so popular.

These include:

- V-Lock system for easy attachment and securing of the header to the trailer

- Main frame painted to match the combine brand colour – powder coated and oven-baked

- Galvanised supports keep the trailer looking new – for enhanced residual value

- Accurate following and turning into gateways whether behind the combine or a tractor

- Standard tyres 260/75-15, but with options up to 22-ply

- Heavy-duty, 10t-rated axles

- Heavy-duty, twin-beam construction available on 40, 45 and 50ft header trailers

- 40mm/50mm drawbar eye options

- Overrun braking (so trailer always brakes effectively whether behind the combine or a tractor)

- Back-up from the official UK importer – spare parts readily available.

Agco dealer view

Main Agco dealer, Chandlers Agricultural recommends Ziegler headers – especially to customers operating Ideal combines with the widest SuperFlow or Geringhoff headers. “We don’t use any other brand now,” explained Chandlers harvesting dealer principal, Sean Stanfield. “When we assemble the trailers after shipping, everything fits perfectly, and they are incredibly well made.

“Customers love them, and they tow like a train. We use a Ziegler 4WT trailer to transport our demonstration combine headers and, often when we turn up on a farm, the first thing customers comment on is the way the header trailer negotiates turns. Headers lift on and off easily and lining them up is never a problem.”

Sean said that Ziegler has also developed a version of the trailer to transport heavier flex Draper headers. “Since last year, we have been able to supply Geringhoff Flex headers as an approved option for Agco Ideal combines, and our demonstration machine was very busy last harvest. The Geringhoff header, with its ability to flex, requires extra support for transport and it’s heavier, but the specially designed Ziegler trailer makes it as easy to move about as a conventional header.

“The back-up from Ziegler and the Abrey team is always excellent, so the trailers are an obvious choice.”

Essex-based farmer’s experience

Essex-based farmer, James Nott farms near Clare, and he replaced two John Deere combines with 35ft headers, with a single John Deere X9-1100 with a 45ft header, just before the 2021 harvest. He chose a Ziegler trailer.

“I have always got on well with Toby Abrey and the rest of the Abrey Agricultural team,” he said. “I used two different brand header trailers with my previous combines, but the Ziegler 4WT trailer was the obvious choice for the new, wider 45ft header.

“Ziegler’s build quality is very good – better than any other brands I have tried, and the trailer does just what it was bought to do. It turns easily through narrow gateways and the wheels follow the path of the tractor precisely. There have been occasions when I have watched it enter a field and doubted whether it could make the turn, but then it just does – it’s very successful.”

Trailer success led to header purchase

In recent years, James has diversified into growing grain maize. A small area was grown as a trial for the 2021 harvest, more was grown successfully last year and now an even larger area has been planted for the 2023 harvest. A conventional combine equipped with a specialist maize header harvests the grain and, after becoming convinced of the crop’s benefits, James ordered his own 12-row Ziegler header for his John Deere X9 combine from Abrey Agricultural through his local John Deere dealer, Tuckwells.

Several brands were considered before James ordered the Ziegler. “I’ve been very impressed by the build quality and performance of the Ziegler trailer, and I know that the Abrey team will provide excellent back-up, so buying a Ziegler header through Tuckwells, which also supplies and looks after our combines seemed the obvious choice.”

Recommends Ziegler

Tuckwells group sales combine specialist, Steve Bucket said that he always recommends Ziegler trailers to customers. “Toby and the rest of the Abrey team are very easy to deal with and the Ziegler trailer is so good,” he stressed. “We’ve seen a big increase in numbers of four wheel-steer trailers sold recently as this sort of arrangement is essential for moving flex headers over 30ft cutting width on the road.”

View trailers for sale on FarmAds.

SsangYong Musso pick-ups are gaining a strong reputation among the farming community, as recent versions combine good build quality with comfort and great load carrying capability. Farmers Guide‘s David Williams tried the latest version.

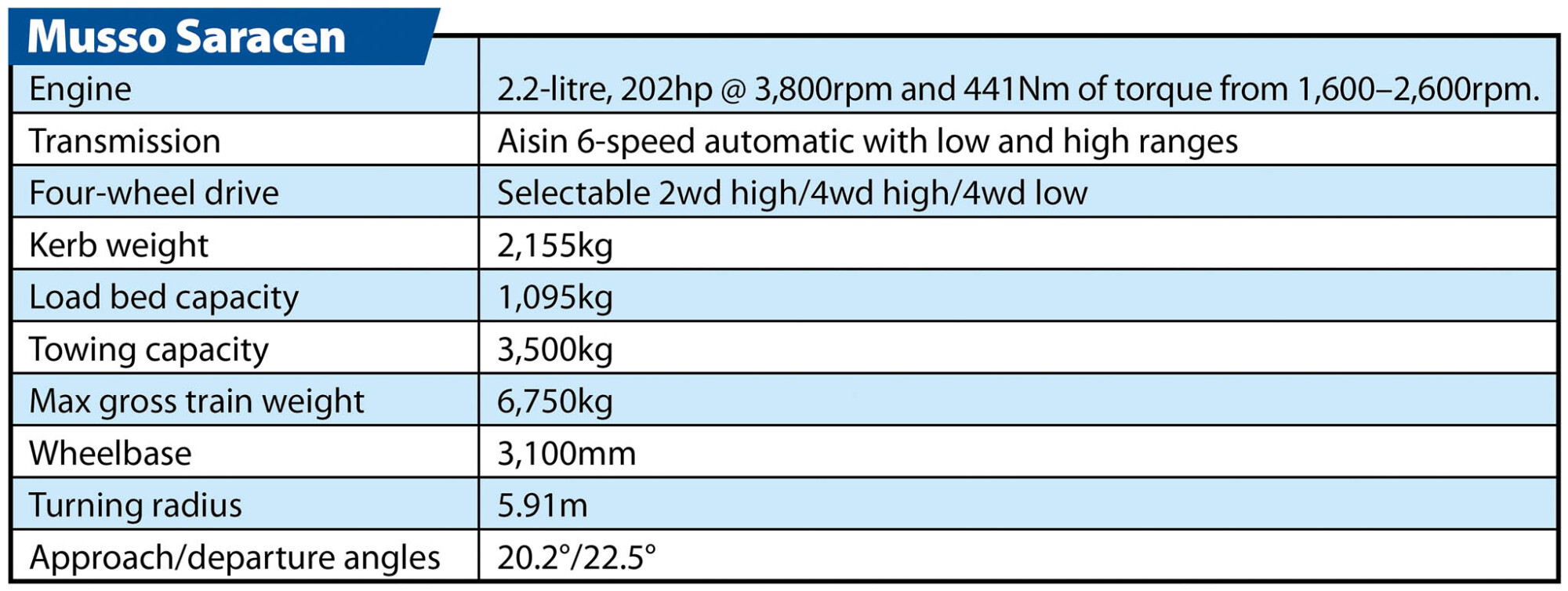

There are four equipment levels to choose from, including the base EX, mid-specification Rebel, and the flagship Saracen with a standard length load bed or the Saracen+ with a slightly longer load area. All share the same 2.2-litre diesel engine, and the EX comes only with a six-speed manual transmission, whereas a six-speed automatic is standard for all other models. The version supplied for the Farmers Guide week-long test was the Saracen, with a standard load bed.

Latest models introduced have more power and torque than their predecessors and the manufacturer also claims improved fuel economy, as well as reduced emissions. The new models boast upgraded suspension and a revised interior for greater comfort and an improved driver and passenger experience.

The Saracen has a generous equipment specification, including nappa leather seats.

Interiors

The large seats are comfortable for long journeys and practical for farm use as they are easily wiped clean. The front seats have electric position controls and are heated and cooled. The rear seats are heated. There is plenty of legroom in the front, and the amount of rear space is reasonable – even with the front seats right back, allowing four adults to travel in comfort. The climate control works well, and there is plenty of air conditioning capacity to keep the accommodation cool on hot days. The rear seat passengers have their own air vents integrated within the rear centre console.

Storage options include large pockets in all four doors, a large lockable glovebox and a generous size box in the centre console. There are also drinks holders and handy trays near the gear selector, and a tray on top of the dashboard.

The Saracen comes with a 9.2-in touchscreen which displays images from the rear-view camera and provides navigation and infotainment. Apple CarPlay and Android Auto compatibility is standard.

The main gear selector has fully automatic and manual override selection modes, and for manual operation a small toggle switch at the top of the selector lever makes the changes.

A rotary dial behind the gear lever selects 2wd or 4wd and high or low range. Additional driver assistance is provided by hill start assist and hill descent control. Unusually for a modern pick-up, the Musso has a traditional mechanical handbrake in the centre.

The finish quality is very good and farmers who viewed the pick-up during the test drive week were genuinely impressed.

The load bed is one of the largest in its class, and SsangYong claims the highest legal combined load bed and trailer towing capacity with a maximum gross train weight of 6,750kg.

Practicality

SsangYong claims that the Musso is the only pick-up legally able to tow a 3.5t trailer and carry a one-tonne payload simultaneously. Trailer sway control is standard, adding confidence for those utilising the towing capacity. The test vehicle had a load liner fitted, plus a roll cover. The usable load bed was 130cm long, had a maximum width of 159cm and 115cm between the wheel arches. The tailgate opening is 137cm wide. The roll cover is practical and secure but restricts the space for larger items. Fully retracted, the opening is 94cm long and 140cm wide. There are four internal tie down points.

Performance and comfort

The large engine has plenty of power and the Musso handles loaded trailers on- and off-road easily. At 70mph on motorways it is quiet and there are no vibrations or rattles but, even without a load on board, slight inclines cause the transmission to shift down a gear to maintain constant speeds. The new Musso has double-wishbone front, and double-coil spring rear suspension and the set-up works well. Carrying heavy loads in the cargo bed, there is little body roll on corners and the vehicle feels secure. When empty, uneven surfaces are felt more by occupants, but the ride remains comfortable. The vehicle was driven across heavily rutted fields in wet conditions. There was adequate ground clearance and the Pirelli Scorpion 255/60R18 tyres maintained traction and steering control.

Overall, during the week-long test which included some longer journeys, the Musso achieved an impressive 36mpg fuel economy.

Maintenance

Routine oil level checks are easy to carry out with a dipstick near the front of the engine, and the windscreen wash filler is on the right-hand side and easily accessible. Service intervals are every 12,500 miles or 12 months, and Musso pick-ups come with a five-year, 100,000-mile warranty.

Chandlers dealer principal, Richard Young.

Verdict

The Musso Saracen has a quality finish and is extremely well equipped. The practical leather seats are an advantage over fabric upholstery in the base EX version, and the simulated leather of the Rebel model. Like other Musso pick-ups, the Saracen is an extremely capable load mover, and latest models also boast a comfortable cabin with space for adults in the front and rear. All-round visibility is very good through large windows separated by narrow pillars, and large rear-view mirrors.

Several large agricultural machinery dealers represent SsangYong and report high levels of satisfaction from farmer and contractor users. The Musso line-up starts at £25,140 (exc VAT) on the road for the EX, making the base model an attractive option for use around the farm and locally, while the Saracen tested costs from £32,540 but comes with useful additional features and extra comfort for family use and longer journeys.

Limited options for farms

During the past decade, the number of options in terms of 4×4 commercial-type vehicles suitable for farms has dwindled. Several panel van manufacturers offer 4wd as an option, but when it comes to vehicles with extra ground clearance and true off-road capability suitable for transporting tools and parts to machines broken down away from the yard there are few to choose from.

Premium solution

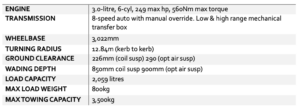

The Defender commercial, designated Hard Top, is available in short (90) and long (110) wheelbase models and with a choice of engines. Both models are available in a range of equipment levels, starting with the base Hard Top, then the Hard Top S, SE, HSE, X-Dynamic HSE or X variants. The D250 power unit with 249hp and 570Nm of torque is fitted in Standard, S and SE variants, and the D300 engine with 300hp and a massive 650Nm of torque powers X-Dynamic HSE and X models. All engines are mild hybrid, which means they won’t run on a battery alone, but electric drive assistance during acceleration helps reduce fuel consumption and emissions.

The Defender commercial, designated Hard Top, is available in short (90) and long (110) wheelbase models and with a choice of engines. Both models are available in a range of equipment levels, starting with the base Hard Top, then the Hard Top S, SE, HSE, X-Dynamic HSE or X variants. The D250 power unit with 249hp and 570Nm of torque is fitted in Standard, S and SE variants, and the D300 engine with 300hp and a massive 650Nm of torque powers X-Dynamic HSE and X models. All engines are mild hybrid, which means they won’t run on a battery alone, but electric drive assistance during acceleration helps reduce fuel consumption and emissions.

Automatic eight=speed transmission with manual override is standard, and a mechanical two-speed transfer box provides a manually selected low range for extreme off-road situations.

The model supplied for the Farmers Guide test was the Defender 110 D250 in the mid-spec S trim level.

Land Rover Defender 110 Commercial D250

Practicality

A full-height mesh bulkhead behind the front seats ensures the driver, passengers and load remain separate even during heavy braking. The Hard Top version is based firmly on the standard model, but the rear windows are replaced by solid panels, the rear seats have been removed and replaced by a full-length, flat floor, and space that would have accommodated the passengers’ legs has been cleverly converted to underfloor storage.

The long wheelbase (five-door) version tested retains its two rear passenger side doors, and these add convenience for loading.

Total load volume is impressive, at 2,059 litres. The lockable storage under the floor adds 58 litres just inside the rear door, and 155 litres behind the front seats. Opening the rear side doors exposes horizontal hatches which provide access to the underfloor storage even when the load area floor is completely covered.

Access to the rear load area is less convenient than it would be for a large panel van, as the doors were shaped for passenger use rather than for loading bulky items.

The rear door is 90cm high, and the opening width is between 96 and 106cm. The single-piece door has side hinges and opens easily. The side hinged opening means it is easy to stand at the rear and reach loads inside by hand, or using a forklift, but opening the door fully requires a lot of clearance.

With standard coil spring suspension the ride height is fixed, and the load floor is 83cm above ground level at the rear, and 92cm through the side doors.

The internal load area is 147cm long, and 146cm wide just behind the bulkhead at floor level, increasing to 152cm wide higher up, At the rear, just inside the rear door the usable width is 111cm.

There are four hefty tie-down points.

Towing capacity is 3,500kg, even with the maximum 818kg payload.

The test vehicle was equipped with an optional third centre seat. Space is tight when transporting three adults, but it is reasonably comfortable for shorter journeys.

Comfort and controls

The Defender Hard Top comes standard with just two front seats, but the test vehicle also had the optional third seat between the two standard seats. The seats are all comfortable, although the centre seat is slightly higher. When carrying three adults the cab is quite cosy, and the huge number of grab handles is a help when travelling over uneven ground. For shorter journeys the accommodation is adequate, and being able to occasionally carry three people will be an advantage for most farms and contracting businesses. When the centre seat isn’t needed it can be folded to create a flat space suitable for resting a laptop, and it also contains two large cup holders. It is a very practical design.

Like passenger versions, all the main controls are dashboard mounted – including the gear selector. Gear lever positions in auto mode are Reverse, Neutral, Drive and Park. Manual gear shifting is available by pushing the gear stick to the left and then pushing it forward or pulling it back. There are no steering wheel paddles.

Heavily rutted woodland tracks and muddy fields were no problem for the capable off-roader.

Superb off-road

All Defenders come with Terrain Response. This allows the driver to select drive characteristics to match the terrain using a rotary dial which doubles as the driver’s side temperature control. Options include Eco, Comfort, Grass/gravel/snow, Mud ruts, Sand and Rock Crawl. A separate button selects low range which reduces the gear ratios considerably, but the vehicle must be stationary.

The test week included an opportunity to try the Defender in demanding off-road conditions in woodland. Forestry machinery had created deep ruts, and the heavy, wet ground was extremely slippery. Even so, the Defender coped perfectly well in the standard road driving modes, although when the Mud ruts mode was selected there was noticeably more traction as the differentials locked, and the vehicle felt more capable. The powerful engine was superb – and the huge amount of torque produced meant that the Defender maintained constant low speeds as conditions varied easily, at just over an idle.

The Defender 110 Hard Top is ideal for transporting tools and equipment around the farm but has a high price tag.

Performance and handling

On the road, the large Defender also handles well. The suspension is very firm but comfortable and there is little body roll when cornering. The big engine is smooth and exceptionally quiet, and there is very little wind noise contributing to a high level of comfort during longer journeys.

Official acceleration figures include a 0–60mph time of just 7.9 seconds, and a maximum speed of 117mph.

The test week included a wide range of driving situations from motorway use to the woodland tracks, and average fuel consumption was 28.5mpg. Where permitted – 70mph is achieved at approximately 1,500rpm, and on a longer journey the Defender achieved almost 38mpg.

Ease of use

All-around vision is excellent. The external mirrors provide a clear view down the sides, and the test vehicle also had the optional ClearSight internal mirror. The view through a conventional mirror would be partially obstructed by the full-height mesh bulkhead as well as loads in the rear, but the ClearSight mirror is a screen which displays an image from a camera at the back of the vehicle. It works well and improves safety when manoeuvring in tight spaces. The S-specification also includes a 3d surround view displayed on the dashboard screen. This highlights obstructions close to the car and contributes to safe manoeuvring.

All-around vision is excellent. The external mirrors provide a clear view down the sides, and the test vehicle also had the optional ClearSight internal mirror. The view through a conventional mirror would be partially obstructed by the full-height mesh bulkhead as well as loads in the rear, but the ClearSight mirror is a screen which displays an image from a camera at the back of the vehicle. It works well and improves safety when manoeuvring in tight spaces. The S-specification also includes a 3d surround view displayed on the dashboard screen. This highlights obstructions close to the car and contributes to safe manoeuvring.

The 10in touchscreen is clear and easy to use. The menus are logical, and it takes little time to get used to the functions. Apple CarPlay and Android Auto compatibility is standard. The navigation system is the same as in standard passenger variants and it is easy to set up and use.

All new Defenders come with plenty of storage for odds and ends. This includes large door pockets, trays of various sizes in the dashboard, plus a reasonable size glovebox.

Land Rover Defender Commercial: The verdict

For those needing a commercial vehicle that can carry up to three passengers in comfort, perform exceptionally well off-road, and pull large trailers, the Defender 110 D250 Hard Top is hard to beat. However, the attractive package comes with a relatively high price tag. The standard model costs approximately £47,450 + VAT and upgrading to the S specification tested adds approximately £2,860 + VAT. Additional options fitted to the test car included an electric folding towbar, the ClearView rear mirror, a Tracker, an electronic active differential, the centre front seat, metallic blue paint and off-road tyres which added a further £4,500.

The Discovery Sport joined the Land Rover line-up in 2014 when it replaced the Freelander. It remains extremely popular and that is probably because although it is smaller, easier to drive around town and park, and boasts more stylish lines than the full-size Discovery or the latest Defender, it still has the character and feel of a proper Land Rover. David Williams tried the latest version.

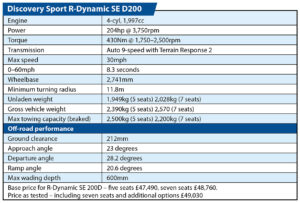

The model provided for the Farmers Guide week-long test was the Discovery Sport R-Dynamic SE with a D200 power unit.

The model line-up features the Discovery Sport as the base version. This comes with a 165hp diesel engine and 2wd, or with the same engine and permanent 4wd in mild hybrid form. The mild hybrid MHEV system stores energy during deceleration and when travelling downhill, then uses the electrical power to assist the diesel engine during acceleration to save fuel and reduce emissions.

The Discovery Sport R-Dynamic comes in permanent 4wd form only, and in SE or better equipped HSE variants. The SE includes a choice of four engines including the D165 – a 165hp diesel with MHEV, as well as the D200 204hp diesel with MHEV, a P250 249hp petrol with MHEV and the most powerful P300e petrol/plug-in hybrid with 309hp.

There are also two ‘Edition’ models – the Discovery Sport Urban and Discovery Sport Black. The Sport Urban has a choice of the D165, D200 or P300e power units and the Sport Black is available only with a P290 290hp petrol engine.

The Discovery Sport R-Dynamic SE we tested comes with a generous standard specification, and the option of five or seven seats.

Interior and comfort

The seats are comfortable, with adequate legroom for a tall driver and front seat passenger. The driver’s seat has 12-way adjustment which makes it easy to achieve a comfortable driving position and once it is set the seat position can be stored within a driver profile for recall at the touch of a button. The Discovery Sport is more compact than the full-size Discovery and with the front seats right back, there is limited leg room in the second-row seats. Moving the front seats forward only slightly makes a big difference to the leg space in the rear, and four adults can undertake long journeys in comfort.

The test vehicle had optional third row seats. When these aren’t needed they fold under the rear load area leaving an almost flat floor, but for use they fold out in seconds complete with full three-point retractable seat belts. Getting into the third row involves tilting the second-row seats forward and entering through either of the two rear doors. The rear-most seats are very shallow and close to the floor making them best suited to use by children. However, making best use of available space in a vehicle is always a compromise, and if the ability to transport seven people safely is needed, then the Discovery Sport provides a practical solution.

The interior is smart but functional. The steering wheel is chunky, and the integral switches are easy to use.

Friendly design

The 10in touchscreen display is easy to use. The driver can select a full-screen display for navigation or divide the screen into sections so that a reduced size map, telephone and media are all displayed simultaneously. The sat-nav system is good and menus are logical and intuitive, so it takes little time to get used to them.

The view through the windscreen and large side windows is good, and the external mirrors are well positioned to negotiate narrow gaps and tight gateways. A 360-degree camera displays an outline image of the car on the centre display along with any objects nearby and, when reverse is selected, there is a clear image from the rear camera on the screen.

The R-Design SE comes with a fixed full-length panoramic glass roof. An internal blind operates electrically, and when it is retracted the interior is a lot brighter and the car feels more spacious.

There is plenty of room for four or five adults to travel in comfort. The test vehicle was a seven-seat version with two additional seats in the rear, but limited leg space means they are better suited to transporting children.

Practicality

With the third-row seats folded away there is a reasonable load area, and this can be further extended by folding the second-row seats forward. The load space is almost flat making it suitable for large, heavy items and there are strong tie-down points to secure loads. The one-piece rear door is hinged at the top. This makes it easy to reach deep inside the boot to place or remove heavy items, but it is more difficult to open the door where space is limited.

There is plenty of storage, including large pockets in the front and rear doors. The glovebox is shallow, but there is a storage box with a lid in the centre console, a large open storage compartment in front of the gear selector and two large drinks holders also in the centre.

Second and third row seat occupants also have drinks holders.

The test vehicle didn’t have a tow bar but judging by the performance on hilly terrain the D200 power unit will easily handle trailers up to the 2,200kg maximum. Trailer stability assist is standard.

Other practical features include puddle lights that assist while entering and exiting the car in the dark, power folding external mirrors with automatic dimming on the driver’s side and Blind Spot Assist which displays a subtle but clear warning in the mirrors if a car or other object is in the blind spot beside the vehicle.

The Discovery Sport is a roomy and comfortable family car, but impressive off-road capability including plenty of ground clearance means it will also transport people and equipment around the farm when other 4×4 vehicles aren’t available.

Performance and handling

The D200 engine is smooth and quiet. On the road, the Discovery Sport cruises easily at 70mph, and there is plenty of acceleration to pull away briskly from junctions in heavy traffic. Most of the time, the nine-speed automatic gearbox changes so smoothly that the gear shifts are not noticeable except under rapid acceleration, but in some situations when changing speeds frequently in heavy traffic, a new gear is selected and the drive re-engages with a jolt.

Selecting manual gear shifting instead of auto is achieved by pushing the gear selector to the left. Moving the lever backwards and forwards changes up and down through the gears, or the gear selector paddles behind the steering wheel can be used instead. Returning the lever to the right position re-selects automatic mode. There is also a temporary manual override function. Operating the steering wheel paddles selects manual mode with manual shifting for a limited time after which automatic mode resumes.

The week-long test included a mix of long motorway journeys as well as travel on narrow rural roads and rough farm tracks, and the flexible engine and transmission performed well.

Farmers Guide put Land Rover’s Discovery Sport through its paces on- and off-road during a

week-long test.

Adapts to terrain

The Discovery Sport comes with Terrain Response 2, which constantly monitors the driving conditions and terrain and configures the engine and transmission to suit. Although the system is extremely capable, there is also the option to select the driving mode manually. Settings include Comfort; Dynamic; Eco; Grass/Gravel/Snow; Mud & Ruts; Sand and Wade sensing. Most of the time we had Eco mode selected which was adequate in almost every situation but selecting the soft sand setting when driving across freshly cultivated ground meant lower gears were selected with higher engine revs, and the vehicle became more responsive.

Additional driver assistance features include All Terrain Progress Control, Hill Descent Control and Hill Launch Assist, although the car is so capable that for most situations the standard automatic settings are adequate.

It is a very easy car to drive and it feels compact and nippy on narrow, winding roads. The ride quality is good and there is little roll on corners. The suspension is firm but comfortable and it copes well travelling along pot-holed back roads and rutted farm tracks at speed. The tyre equipment was standard for this model and version, and the Pirelli All-Season 235/50R20s were quiet and gripped well on and off road.

Overall, during the test week, the Discovery Sport achieved 39.8mpg average fuel consumption, and on a longer motorway journey it exceeded 43mpg.

The test vehicle had Land Rover’s D200 diesel engine which develops 204hp and 430Nm of torque between 1,750–2,500rpm. This is probably the best choice for farm use as there is plenty of power for relaxed towing, but it remains surprisingly economical.

Land Rover Discovery Sport R-Dynamic SE: The verdict

The Discovery Sport is unlikely to be chosen as the main farm transport vehicle. It lacks the rugged practicality, capacity or towing ability of a typical farm pick-up or the bigger Land Rover Defender or Discovery models. However, it is extremely capable off-road, and its ability to carry loads and tow trailers across wet, slippery grassland, handle deep rutted tracks and cross field edge plough furrows means it can contribute to farm transport activities when other vehicles aren’t available.

It’s a large and comfortable car which is suitable for transporting a farm or contracting team between work locations, doing the school run or taking families on longer journeys – although the third-row seats lack the leg room needed for adults. Folding the second-row seats forward creates a large, flat load area capable of transporting parts and equipment.

The Discovery Sport performs well on the road, and as the Farmers Guide test demonstrated, the D200 version – which seems the best option for farm use, returns impressively good fuel consumption. The HSE upgrade comes in at just under £2,500 more than the SE, and that adds front fog lights, an improved sound system, 14-way electric driver seat adjustment, an adjustable rear seat and Configurable Dynamics which allows aspects of the car’s handling including steering and suspension to be adjusted to suit the driver’s preference.

The car has a chunky feel, it is ruggedly made and, although it is at the lower end of Land Rover’s line-up, it remains worthy of the badge.

One of the big farming news stories last year was the sale of one of the UK’s largest arable farming businesses – Strutt & Parker (Farms) Limited. Under the new regime, since September last year, preparations have been made to establish a new streamlined fleet of plant and equipment with a select group of manufacturers and to dispose of almost all the existing machinery. David Williams has been finding out when and how.

Suffolk-based Clarke & Simpson is handling the dispersal sale and the original intention was to host two on-site auctions on consecutive days at Strutt & Parker (Farms) Limited’s Lawn Hall Farm, Essex base, and at Thorpe Morieux in Suffolk; creating what would almost certainly have been the largest active farmer on-site farm machinery dispersal sale ever to take place in the UK. However, problems created by the Covid-19 pandemic meant a rethink was needed. “Within social distancing guidelines it would have been impossible to stage a conventional on-site sale currently,” pointed out auctioneer James Durrant. “Also, the delivery of the new machines has been delayed, so a core fleet has to be retained for this harvest and for autumn crop establishment. Therefore, we have decided to launch an online auction which will include selected lots in late June, with the remaining machinery due to be sold later.” Those interested in bidding can view the machinery on Clarke & Simpson’s website at any time, and also on-site at Lawn Hall Farm, near Great Dunmow, Essex on the 24th, 25th and 26th June, while the auction is in progress.

Attractive sale

James says the sale is expected to attract a lot of attention and competitive bidding for the lots on offer. “We are delighted to be instructed by Strutt & Parker (Farms) Limited to sell its machinery. Our original plans had to be rearranged due to Covid-19, but once restrictions were relaxed enough to allow viewing while adhering to social distancing requirements, the decision was made to proceed with the first auction before harvest as a timed online sale. This comprises cultivation and potato equipment, drills, fertiliser spreaders, trailers and combines as well as two backhoe loaders, a telehandler and two Challengers. We expect the remaining machines to be sold later in 2020.”

The online sale starts at 9am on the 24th June and is due to conclude at 12pm on 29th June. A clever feature of the online bidding system is that when bids are placed for any lots within the final 10 minutes of the scheduled running time, then 10 additional minutes are added during which further bids for that lot can be placed. This continues with 10 minutes added after each most recent bid, so bidding for the most attractive lots can continue for many hours after the advertised finish time.

Lots on offer during an online dispersal sale by Clarke & Simpson on behalf of Strutt & Parker (Farms) Limited include tractors, harvesters, cultivation machinery and drills as well as a wide range of other equipment from the 8,000ha farming operation.

Clarke & Simpson auctioneer James Durrant (pictured above) says the sale, between 24th and 29th June, will attract buyers from end-users to trade and from the UK and overseas.

In excellent condition, this Kuhn/Rauch AGT6032, 32m 5t trailed boom spreader was new in 2014. It is on Firestone 520/85R46 tyres with 95 per cent remaining tread.

This Simba Great Plains 6.6m CultiPress CP/66MF/FW is tidy. Many points are new, the press discs are sound, and the tyres have plenty of tread. A few levelling paddles need replacing and there is evidence of minor frame repairs, but this heavy cultivator is likely to generate competitive bidding.

One of the sale highlights is this John Deere 670i combine harvester. Registered on an 11-plate and new in May 2011, it has recorded 2,041 engine and 1,585 drum hours. It’s on 800/65R32 drive tyres with 90 per cent tread, and 540/65R30 rear tyres and comes with a straw chopper, 625R 25ft tilting header and a Shelbourne Reynolds twin-axle header trailer.

One of two Challenger twin-track crawlers available for bidding. This MT765C was supplied new to the farm in 2011 and carries a 61-plate and its original RW Crawford main dealer stickers. It is very tidy inside and out, has recorded 5,308 hours and is equipped with double-acting spools, Cat 4 linkage, FarmForce front linkage, front idler weights and TopCon guidance. The tracks have 20–30 per cent tread remaining but the carcase is poor with the inner layer showing in places. The track rollers appear serviceable, but the rubber will soon need replacing.

This Challenger MT775E twin-track crawler carries a 2014 64-plate and has worked 4,678 hours. It’s equipped with five double-acting spools, Cat 4 linkage, Lynx Zuideberg front linkage, front idler weights and Trimble guidance. The tracks are in very good order with 95 per cent remaining tread and the rollers are good with minor stone damage. Overall the MT775E is in very good condition and is likely to attract competitive bidding.

It’s not often that elderly slurry tankers create excitement, but this very original Massey Ferguson 100 model with its original decals and Eastern Tractors dealer stickers is likely to appeal to classic tractor enthusiasts as an unusual implement to add to a collection. The pump is described as needing attention, but the rear splash-plate applicator with a manual and hydraulic valve is intact. The Good Year Traction Sure Grip 13.4-15-26 tyres both appear sound.

This Heath Superchaser Extra bale chaser is likely to attract competitive bidding. It’s on Michelin Cargo 560/60R22.5 tyres with 40 per cent remaining tread and the chaser carries 12 Hesston bales. The 2016 model is in superb condition and appears ready to put to work.

After the prolonged spring drought, irrigators are in high demand and this Irrifrance Javelin 100-400 reel and rain gun is likely to achieve a good price.

This Farmhand flat-8 bale grab with a JCB Q-fit bracket is tidy.

Among potato machinery lots on offer, this Scanstone trailed windrower model WD17 2+5 was new in 2014, and is set for 72-in beds.

Other potato machinery on offer includes this Grimme Combi Star CS1500 destoner described as for spares or repair. It carries G&J Peck dealer stickers.

There are plenty of wheels and tyres to bid for, and these Trelleborg Twin 750/45-30.5 fronts with 30 per cent tread and 850/50-38 rears with 90 per cent tread – with centres to fit a New Holland 6090 will appeal to both farmers and trade buyers.

For a Claas Jaguar forage harvester – this Kemper 375 12-row, hydraulic folding maize header was new in 2013 and appears ready for work.

Two Ford Transit Connect T220 90 vans are available for bidding. Pictured is a July 2009 registered example with 110,625 recorded miles. It’s MOT’s until July this year. Condition is generally tidy although the sills have a few knocks and there are minor scuffs to the paintwork. The interior is average for its age.

Several Kverneland ploughs are in the sale and this LD100-300-H-HD 5+1f reversible has a 300hp headstock and is in good order. The mouldboards are all serviceable although a few are close to needing replacing.

This Marston BT8 8t twin-axle flat trailer has a steel bed and is on 340/65R18 Good Year wheels and tyres with approximately 20 per cent remaining tread. It was new in 1986 but is in very good condition with a sound steel bed. Brakes are hydraulic.

During Farmers Guide’s visit a Maschio Recotiller 5m hydraulic folding power harrow was on the trailer ready to be moved to the Chelmsford auction venue. The power harrow is an Erpice Aquila 5000 model, new in 2010. It has hard facing on the tines, a rear spiral packer roller and carries its Thurlow Nunn Standen dealer stickers.

These two Vadersdtad Rexius Twin cultivator presses are expected to sell well. On the left is a 2000-manufactured 5.5m 550 model which is tidy and has been modified to include an extra third row of tines. The discs are serviceable, and part worn. The newer 2008-manufactured 6.3m 630 model has two rows of tines and the cultivation discs are almost new. Both were supplied by local main dealer P Tuckwell.

This set of Jean de Bru 3.4m trailed discs was new in 1991.The machine appears in good, serviceable condition and the discs have plenty of remaining wear.

These Simba 2B 16ft hydraulic folding trailed discs were new in 1985, and are in good condition. The discs all have cutaways and have plenty of remaining working life. The tyres are sound but perished.

This set of Quivogne APX TL 4.8m trailed discs was supplied by local dealer Blytrh & Pawsey in 1996. The front discs have cutaways and the rear discs are plain and all are in very good condition.

With its original Thurlow Nunn Standen dealer stickers, this K-Two Airo 2.3m single-row swath turner appears ready to use.

With the wet winter not yet a distant memory, it’s likely that many growers will prioritise ditch and drain maintenance this autumn. This Michael Moore Moles two-leg mole plough comes with an additional fitting for a third leg and is in tidy order.

This JCB 3CX Contractor backhoe-loader is likely to prove an attractive lot and would be an ideal investment for those keen to take ditch maintenance in-hand this year. It’s registered on an 05-plate and is on BKT 18.4-26 rear tyres. The 3-in-1 bucket appears in good order, the cab is tidy and overall the whole machine appears well maintained. There is a small amount of rust around the front radiator grill and the in-cab display doesn’t display the working hours but otherwise there appears little to criticise.

Two similar Fraser M20 trailers are on offer. Pictured is a 14t, 2001 model with a hydraulic tailgate, sprung drawbar and on a mix of Trakmila and Fulda 385/65R22.5 wheels and tyres. The trailer has been repainted but needs some tidying and is likely to see use with a new owner this harvest.

Richard Western trailers on offer include this RC14 14t twin-axle root crop tipping trailer which was new in 2007. It has a sprung drawbar, hydraulic tailgate and hydraulic braking. The tyres are 385/65R22.5 with 40 per cent remaining tread and the trailer carries its original Ernest Doe Power dealer stickers.

This Kuhn Axis 30.1 twin-disc 24m fertiliser spreader is in superb order for its age. It was new in 2011 and is fitted with a hopper camera, hopper extension and cover.

Expected to achieve a high price is this Kverneland Accord 6.0m hydraulic-folding power-harrow drill combination. It was new in 2012 and comprises a Kverneland NG-S101F35 power-harrow with wheel track eradicators and a packer, and an Accord DF2 drill with two rows of disc coulters, covering harrow, tramline and pre-em markers, plus a front-mounted hopper.

This West Samurai 5 500/150 trailed straw/ green waste chopper was new in 2017 and is on 315/70R22.5 wheels and tyres. It carries its original WM Agri dealer stickers.

This large 8m Simba CultiPress comprises two rows of spring tines, levelling paddles and a double DD-ring press. It’s in very good condition and the tines have plenty of wearing metal and the discs are in good order. It has its original Ernest Doe dealer stickers.

Those interested in bidding can view the machinery on Clarke & Simpson’s website at any time, and also on-site at Lawn Hall Farm, near Great Dunmow, Essex on the 24th, 25th and 26th June, while the auction is in progress.

A series of mid-October practical demonstration days provided an opportunity for potential and current Unimog users to find out about the latest models. David Williams was there.

Unimogs have been manufactured by Mercedes-Benz since 1948, and the brand’s popularity with UK farmers and agricultural contractors is growing. Superb performance for transport tasks has become the primary reason most farms invest, while low running and ownership costs increase the appeal. Exceptional off-road performance plus a range of attachments including three-point linkage and PTOs, means they can also double up as a tractor for field work including light cultivations.

The four ‘Unimog on the Farm’ demonstration days were strategically located around the UK including Yorkshire, Suffolk, Gloucestershire and Fife, and this year’s event included an invitation for owners of heritage machines to bring them to display. A presentation by Unimog specialists at each location highlighted design features and benefits of the latest models, and provided an overview of the range.

Up to 300hp

The Unimog line-up includes UHE extreme off-road models, and UGE all-terrain implement carrier variants.

UGE models account for most UK sales and are supplied for on- and off-highway applications. In total, there are 10 models in six wheelbase lengths in the Unimog line-up.

Combining the off-road ability of a tractor with commercial vehicle handling, braking and steering, the Unimog can travel, where permitted, at up to 90kph. High payloads can be carried and the largest model in the UGE range – the U530, has a permissible gross vehicle weight up to 40t, depending on the trailer and body.

Fuel consumption figures are impressive – averaging between 7.4–11.5mpg for a range of tasks, and with 1,400-hour service intervals, running costs are low. Three years’ warranty is standard, and up to five years is an option. Used Unimogs sell well, attracting high prices, so depreciation is low.

All Unimogs have a mechanical transmission providing working speeds from 0.13–90kph. Hydrostatic drive is available for extra flexibility, and is fitted in addition to the standard transmission. When infinite speed control is needed, the clutch drive disconnects from the engine and the hydrostatic motor provides drive to the gearbox, with power supplied from the vehicle’s hydraulic system.

Back-up for the vehicles is impressive and although there are only four specialist sales outlets covering the UK, there are also 23 specialist service dealers, but for breakdowns the whole Mercedes-Benz commercial vehicle network is available, ensuring minimum downtime. Add to this that over 94 per cent of parts ordered are immediately available from UK stock, with non-UK parts supplied within

24 hours, and the after-sales support is excellent.

For users needing to fix costs of ownership; service and extended warranty packages are available. Three years’ servicing, with full driveline and vehicle warranty, costs £280 per month, and budgeted servicing up to five years is available, with full factory warranty.

Agricultural appeal

The demonstration days gave existing users an opportunity to meet and discuss experiences, and allowed potential users to experience the range of Unimogs at work. Farmers Guide attended the Yorkshire event, where a woodland test track with deep, muddy ruts would have stopped most other off-road vehicles but didn’t even require diff-lock engagement on the Unimog U5023 UHE and U423 UHG models tested.

An on-road course over a few miles provided an opportunity to tow a large trailer at higher speeds, and a wide selection of mounted and towed agricultural implements including mowers, rakes and a forage wagon were each matched with suitable models for a grassland working demonstration.

Although Unimogs are unlikely to be chosen over conventional tractors for primary cultivations, their ability to perform field work if needed helps justify a place on the farm or contracting fleet. Most agricultural users select Unimogs for their efficient farm transport capabilities, saving time and fuel, but equipping machines with a PTO and rear linkage means they can perform the work of medium-sized tractors if a breakdown occurs or during busy periods. Central tyre inflation is a popular option, allowing pressures to be increased for road travel, then decreased at the touch of a button for field work. Unimog’s design includes air supply pipelines running through the axles with no risk of snagging on obstructions. According to head of Unimog Katie Purcell, investing in central tyre inflation and a PTO makes a lot of sense, increasing versatility, but also enhancing resale value later.

Another useful option for farm work is VarioPilot. This allows the user to move the steering wheel and pedals for left- or right-hand drive. No tools are needed, and the user simply releases the locking lever, removes a dashboard panel and slides the steering wheel and pedals across. The process takes just a few minutes and, for tasks such as verge cutting, it increases convenience and safety. Other situations where it assists the user include working alongside a harvester when operating the Unimog from the left-hand seat makes it easier to keep an eye on trailer loading progress without neck strain. Because VarioPilot makes the machine compatible for English or European road use, it’s another option described by Katie Purcell as a shrewd investment – appealing to a wider market and increasing the machine’s resale value.

Tasks for which Unimogs are ideal include transporting seed, fertiliser and water to machines working in the fields. Swapping between a rear platform or a water tank takes little time with just four pins to remove and replace to secure the load.

Test-drive

Whether operating in fields or on public roads, the Unimog feels extremely capable and is easy to drive. The cab is spacious and comfortable, and the controls are well arranged. Visibility is excellent, especially to the front where the short bonnet leaves a clear view. Visibility to the rear isn’t as good as from a tractor seat but removing the rear tailgate from the load platform makes it much easier to watch rear-mounted implements.

Manoeuvrability is good and was highlighted by the ease with which tight turns were negotiated on the woodland test track. The steering itself is light but has a reasonable amount of ‘feel’.

A wide range of transmission settings is available, including front, rear and centre diff-locks but, as the Unimog proved so capable in the muddy conditions, the standard full-time 4wd on-road mode, with automatic gear selection and changing, proved more than sufficient. In manual mode, gear changes are made using buttons on a stalk below the steering wheel and is easy to use.

Ride quality on the road is good, as the tyres and seat soak up most of the bumps, but off-road the ride is harsher due to the extremely stiff suspension, especially with an empty rear load bed.

The cab is reasonably quiet, partly because of its design but also because the engine’s high torque means revs can be kept low, unless PTO-driven implements are operated requiring a constant speed.

Verdict

Sales of Unimogs in the UK are increasing, and with many farms keen to improve compliance with road transport regulations, while also wanting to reduce transport time and costs, this trend looks set to continue. More than 200 new machines have been sold in 2019, and speaking with owners at the demonstration day, it’s clear that a Unimog’s versatility is considered an advantage over conventional tractors and commercial vehicles. One farmer at the event commented that a lorry can transport his crops more efficiently than a tractor from the field edge to the store, but a tractor is still needed as the lorry can’t travel on the field. His Unimog carries out the whole operation from field to yard, and is safer and quicker.

A brand-new tracked tractor has been added to John Deere’s extensive line-up, boasting unique features likely to suit UK arable farms. David Williams took an early test-drive.

Among the updated and new models attracting considerable attention on John Deere’s stand at Agritechnica in early November were its latest 8R tractors. Representing the manufacturer’s most powerful conventional tractors, the 8R series is popular with professional users demanding maximum productivity, so its new models were eagerly anticipated. Previously the line-up included 8R (wheeled) and 8RT (twin-track) variants, with power topping out at 450hp. But the updated series provides an all-new tracked option in the form of the 8RX with four sets of rubber tracks and conventional front axle steering, and maximum power up to 458hp.

8R-series updates

Since John Deere introduced its flagship 9RX with up to 670hp (max) and four equal-sized tracks, the addition of a smaller four-tracked model in the 8R series has been widely predicted. Development and testing since development started in 2016 has been extensive but, despite the fact that this new product launch has been one of John Deere’s largest investments ever, with more than 100 test units operating, the company and customers selected to test the new model did an excellent job of keeping it under wraps and few pictures have appeared of machines working.

With the 8RX model’s official launch planned for Agritechnica this year, Farmers Guide was one of a handful of agricultural magazines from around the world invited to an exclusive press preview this summer. It was at John Deere’s Waterloo tractor production plant and, as well as seeing early units coming off the production line, there was also an extensive test-drive on fields adjacent to the factory.

The full range of 8R models has been updated and, from the outside, the most obvious change is revised styling.

There are five new 8R wheeled models ranging from 280–410 rated horsepower, and John Deere claims class-leading efficiency for the latest line-up with up to 94 per cent total tractor efficiency. All the new models are backed by John Deere’s Fuel Guarantee Programme from the start, for both field and transport tasks.

Power and efficiency

All 8R-series models are powered by John Deere 9-litre PowerTech PVS and PSS engines and meet the latest Stage 5 emissions standards.

The engines are similar to previous models but with extra power, and a new eVisco radiator fan improves cooling efficiency.

Transmission options include 16/5 PowerShift for wheeled models up to the 8R 340, and the e23 with Efficiency Manager is available across the range. AutoPowr IVT is an option for all models except the most powerful 8R 410.

The rear brakes are upgraded, with double the performance of previous versions and can stop the tractor from 50kph more quickly than previous models could from 40kph. The rear brakes are so effective that front brakes aren’t needed up to 50kph, but can be ordered as an option.

Cab upgrades