According to Case IH, the economic, efficiency and environmental benefits of enabling one operator to do more with one machine have influenced the development of its new largest tractor – the Quadtrac 715 AFS Connect. With a peak output of 778hp, it’s reckoned to now be the world’s most powerful production tractor, and sits atop a line of other revised 522–699hp Quadtrac AFS Connect and Steiger AFS Connect tractors, but has distinct styling and other features.

“The Quadtrac 715 development is about more than more power,” said Franz Josef Silber, Case IH product manager for high-hp tractors.

“It’s about ensuring implements are operated at their ideal speed for best performance and higher work rates, and allowing operations to be performed at the ideal time and with maximum output in short weather windows. We also wanted to boost soil protection via a bigger footprint and fewer passes, which also means greater efficiency and minimal trafficked land.”

The Quadtrac 715’s uprated track units increase footprint by 6%, and the 1,008mm drive wheels help ensure engagement with five track lugs for enhanced power transfer, said Franz-Josef Silber.

The Quadtrac 715 features FPT’s Cursor 16L TST engine, making its debut in a tractor. Displacement is 23% greater than the next-model Quadtrac 645’s Cursor 13L TST, delivering 778 peak horsepower at 1,900rpm and 3,255Nm peak torque at just 1,400rpm. TST denotes the twin-stage intercooled turbocharging system, said to ensure fast response under load, while further features include an improved EGR-free combustion chamber, a 2,500Bar common-rail injection system and increased maximum cylinder pressure up to 220Bar, a package said to produce more power with greater efficiency and low fluid consumption. To match the higher output, the rear frame’s wider saddle tanks hold 1,968 litres of diesel.

The larger capacity twin turbochargers each have an air-to-water cooled intercooler, and Stage 5 emissions regulations are met via a simplified selective catalytic reduction (AdBlue-based) system.

The ActiveDrive 8 eight-step/three-range powershift from 116–145hp Maxxum tractors is now an option for the 110–140hp Vestrum models, in lieu of the established CVX CVT.

Track units upgraded

The Quadtrac 715’s new heavy-duty track units are another major change over other models in the Quadtrac range. They provide 6% more footprint, while at 1,008mm the drive wheels are almost 100mm larger, and mean five track lugs are engaged with the drive wheel rather than four, to handle the higher torque and maximise track life.

The Quadtrac 715’s styling is a marked departure from that of its stablemates, with a distinctive new bonnet, which can be raised higher for enhanced service access, with electric raising/lowering via a switch near the cab steps.

A Category 5 drawbar matches the 715’s implement-handling capacity, while an optional category 4 three-point hitch lifts 9,897kg, and up to eight remote valves are supplied from either a 260-litres/min or optional 514-litres/min twin-flow SmartTorque hydraulic pump.

The new 715 sits atop four further new Quadtrac models and two wheeled Steiger options, all also featuring AFS Connect, which retain more familiar styling but also gain new features. They cover a 522–699hp range, from Stage 5 engine upgrades said to improve engine response time by up to 35%. Engines benefit from an updated fuel system with new fuel injection and a new fuel lift pump. Transmission options include PowerDrive powershift and, on models up to the 555, CVXDrive continuously variable transmission.

Cab updates include a roof-top design with new roof lights available, a premium sound option, RAM monitor mounts and additional console storage. A second AFS Pro 1200 display is optional to allow separate monitoring of Isobus implements.

Vestrum now with powershift option

For farmers looking for something with a little less horsepower, Case IH’s ActiveDrive 8 eight-step/three-range powershift, as established on its 116-145hp Maxxum tractors, is now also an option for its 110–140hp Vestrum models for customers not requiring the full capabilities of its CVXDrive CVT. The three ranges have speed bands of 0–10.7kph, 4.3–18.1kph and 0–40kph, while a skip-shift function allows quick powershift step progression. A creep speed option is available for specialist applications.

“Visitors to Agritechnica – or, in the near future, their local Case IH dealer – will also be able to see further Case IH updates and introductions,” said Ross Macdonald, utility tractor product manager at Case IH and Steyr parent CNH Industrial.

“They will include the new Optum 340 CVX tractor and some significant harvesting product developments, plus a revised seven-model Farmlift telehandler range with variable-flow 160-litres/min hydraulics, new smart hydraulic features, an electro-hydraulic self-levelling headstock and multiple cab comfort and operating upgrades.”

The Austrian field event featured one of the first public European demonstrations of the fully-autonomous development of the Case IH Magnum.

Autonomous tractor demoed in the field

A highlight of Case IH’s early autumn field event in Austria was the chance to see at work the fully-autonomous development of its Magnum tractor. Said to have been designed in response to farmer demand in certain regions for equipment to help meet labour challenges, allow skilled staff to be relieved of monotonous tasks and focus on those better suiting their skills, make the most of weather windows and enhance productivity via 24-hour working, this was the first time the machine had been shown publicly at work in Europe.

Beyond its ability to operate autonomously, the tractor has specifications that otherwise match its conventional cousins in areas from engine power to transmission type and implement handling capabilities. The latest development machine can be operated supervised – with an operator as an observer in the cab and able to manage the tractor’s autonomous and other systems – or unsupervised and driverless, being managed and monitored remotely.

“Our research suggests farmers believe such a system will be most beneficial where they can operate one machine in a field and have another working alongside it without an operator,” said Alessio Quatraro, EMEA product manager for autonomous driving at Case IH.

“When the cab is unoccupied, the tractor is started and stopped using the tablet interface via a wireless internet connection. The current incarnation of the tractor is able to operate autonomously at up to 24.1kph (15mph), with perception system development ongoing to allow for higher speeds. With an operator in the cab, it’s possible to operate at field speeds within the machine’s capabilities. Tougher soil areas or hills/hollows can be mapped when planning operations to ensure forward speed is adapted where necessary to account for adverse conditions.”

During operation, a combination of cameras and radar is used to constantly monitor the tractor’s surroundings for obstacles and motion initiation. Using artificial intelligence, a continuous stream of images is processed and interpreted and any obstacles identified. If one is detected, the tractor halts and the owner/manager’s linked smart device receives an alert, allowing the situation to be assessed and the next course of action determined. Should an obstacle detection sensor fail, there are integral fail-safe procedures to operate equipment in a safe mode until human intervention is possible. If a sensor should fail – very unlikely, says Case IH – the machine stops and sends an alert to the operator’s smart device.

UK-based Ross Macdonald said there was more to come at Agritechnica from Case IH, including Farmlift telehandler updates.

“Low light levels and darkness do not affect operation of the tractor and its systems, with additional lights fitted to ensure full functionality of the perception technology is maintained in such conditions,” explained Alessio.

“Once work is completed in a particular field, the tractor can be driven by an operator to its next destination.

“We have displayed our intent in autonomous tractor development at various points over recent years, with the project continuing to advance as systems are thoroughly tested and validated.

“While we continue to adapt, develop and update as technology evolves and legislation changes, we are progressing the project with a long-term goal of commercialisation.”

Out of 8,400 machines manufactured by Merlo in 2022, 7,000 of them were telehandlers, and a significant increase to 7,800 telehandlers is expected this year. Although the home Italian market share remains considerable, 85% of production is exported and the UK is one of the biggest markets taking 10–12% of total production.

Of the machines produced, 50% are destined for agriculture while the remainder are for industrial use and construction.

Ambitious event

The event, at the St Pancras Renaissance Hotel, was attended by 42 of the UK’s 45 Merlo dealers. Merlo handlers were available in the UK for approximately 15 years before Merlo UK Ltd started trading, imported by Selwood.

Merlo president Paolo Merlo and business manager Massimo Biei opened the evening with an address to all the dealers. Paolo stressed that the customer remains Merlo’s focus, and internal manufacturing of 90% of components means that quality is paramount.

Merlo chose a central London hotel for an ambitious event marking 30 years since it founded its Merlo UK Ltd wholly owned subsidiary. There were 42 of the company’s 45 UK dealers in attendance.

Massimo said that part of the secret of making machines that are so easy to use and comfortable is that they are designed in-house using the experienced team’s know-how.

“The agricultural market remains very stable,” he explained. “Often the farm owner is also the buyer of the machine and the main user too, and features such as our effective suspension systems which significantly increase operator comfort have been a real game changer. We want those buying a Merlo to purchase another of the same brand in 10 years’ time.”

Investment in UK

During the past three years, the parent company has invested heavily in the Merlo UK base at Ringwood, Hampshire as well as the sales and product support teams based there. “Our UK general manager, Shaun Groom and his team are all committed to our products and serving our customers. As a private company we are free to invest for the long-term and this will help guarantee success of the brand in the future,” continued Paolo.

Shaun Groom added. “It’s been great to be able to acknowledge in style all those present and that have gone before us during the past 30 years for their success in bringing Merlo UK to where it is today. Whether that be as a customer, dealer, colleague or industry partner, we are truly grateful for the support, and we look forward to the next 30 years. Last year we sold more than 700 units in the UK, which was a great result.”

Pictured (l-r) Merlo president Paulo Merlo, Merlo UK general manager, Shaun Groom and Merlo business manager Massimo Biei with three Merlo handlers displayed in front of the St Pancras Renaissance Hotel for the event.

Dealer awards

Awards were presented to several dealers, two of which had been with Merlo UK since the company’s inception. These were Devon-based CR Willcocks and Wales dealer Brodyr Evans Bros. Brodyr Evans dealer principal, Elgan Evans, said that it had been a privilege to represent the brand for the past 30 years, and he is looking forward to the next 30. Essex-based RC Boreham & Co collected an award for 25 years as a Merlo main dealer.

Looking to future product developments, Massimo and Paolo told Farmers Guide that many farmers across Europe still consider telehandlers to be new products, and that the research and development team works closely with all types of customers and visits them, to ensure the line-up includes the features they need.

Regarding alternative fuels, Merlo already offers its compact e-Worker battery-powered model which was test-driven by this magazine last year. Massimo said that development of medium-sized handlers using battery power is continuing, but that work on future diesel-powered models is also in progress.

Latest features assist future innovation

He added that telematics on existing handlers assist future product development, as engineers can analyse operating data to determine exactly how products are used. “We can identify areas where improvement is needed and make products more efficient.”

Massimo said features such as Merlo’s attachment recognition system, which automatically installs the correct operating profile for each implement, are contributing to extra efficiency. “It allows the operator to work closer to the machine’s limits while ensuring safety,” he explained.

Shaun Groom is pictured with RC Boreham dealer principal Nigel Boreham and director Matt Boreham. The dealer was presented with a long service award marking 25 years representing the Merlo brand.

“It was a fantastic event and everything we had hoped that it would be,” concluded Shaun. “Challenges included getting our three display handlers into central London, but it was very worthwhile and a great way to mark 30 years.”

The new 600-Vario series tractors are designed to compete for a large market share in one of the most popular and competitive market sectors, where tractors with power outputs from 150–200hp meet the needs of arable, livestock and mixed farms and many operate with front loaders.

Fendt’s new models fill the gap between the current 500 Vario and the 700 Vario Gen 6 series. The gap relates more to model numbering than power outputs, as there is already a crossover between the most powerful 516 Vario with up to 163hp, and the current entry 714 Vario with 144hp.

However, the new 700 Vario Gen 7 line-up, announced last year, starts at 203hp and Fendt has already confirmed that the 714 Vario and 716 Vario models will be discontinued in late 2024 – coinciding with early deliveries of the new 600 Vario.

600 Vario

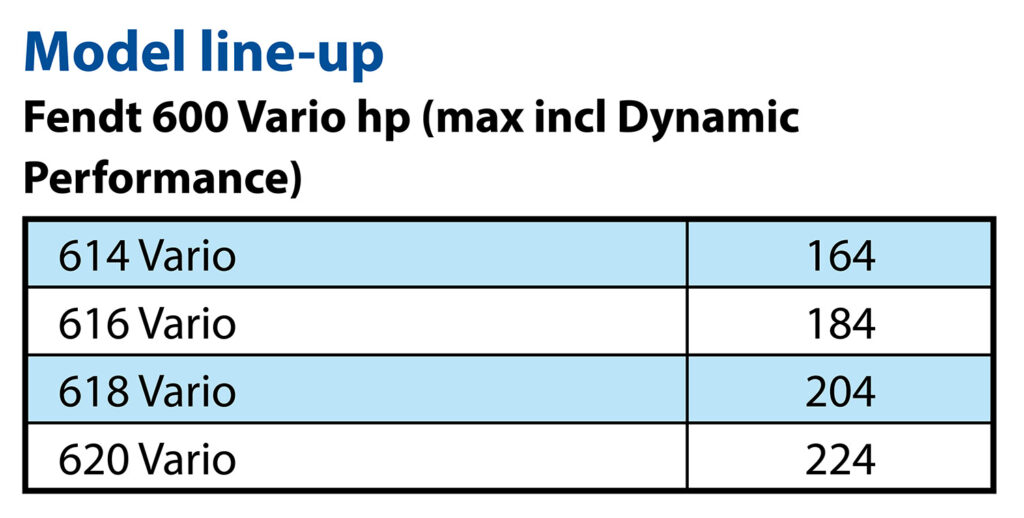

There are four new 600 Vario models, starting with the 164hp 614 Vario. They all use Fendt’s Dynamic Performance design strategy which compensates for parasitic losses including powering lights, air conditioning, power steering and other tractor systems to ensure full power is available at any speed and for any application.

Power is from a brand-new AgcoPower 4-cyl, 5-litre engine. The Core 50 power unit is described by Fendt as ‘little brother’ to the 6-cylinder Core 75 fitted in the new 700 Vario Gen 7 tractors.

The Core 50 has hydraulic tappets to reduce maintenance requirements (services every 500 hours), an electronic wastegate turbocharger which contributes to the flat torque curve, and it is future-proofed with synthetic fuel compatibility.

The new engine has also been designed to operate on methane if models fuelled by the gas are offered in future.

FendtID low engine speed concept

Like larger Fendt models, the 600 Vario-series utilises the FendtID low engine speed concept to maximise efficiency and save fuel. Maximum power is at only 1,900rpm and the flagship 620 Vario develops its impressive maximum 950NM of torque across a wide rev range from 1,200–1,600rpm. The Fendt 620 Vario gains the mantle of the industry’s most powerful 4-cyl tractor, and compared to other makes and models the revs are extremely low.

Fendt UK marketing manager, Ed Dennett told Farmers Guide that the power and torque characteristics of the new 600 Vario-series are like those of competitors’ much larger 6-cylinder engine models.

Exhaust emission regulations are met using SCR (AdBlue) only, with DPF and a DOC, and there is no EGR. The design maximises efficiency and avoids high operating temperatures. AdBlue consumption is quoted as 6.5% relative to the volume of diesel.

The cooling pack is compact and neat to maximise forward visibility, and a conventional belt-driven fan layout is used rather than the concentric hydraulic-drive design of latest larger models. Viscous drive matches the cooling power to the requirement.

For the most demanding applications, a hydraulic blade pitch adjustment option can be specified. This also allows the air flow to be temporarily reversed to blow loose debris and dust from the air intake grill and cooling system. Its operation can be managed through the FendtONE terminal so that it activates automatically at timed intervals or at each headland turn, for example.

224hp from a brand-new 5.0-litre, 4-cyl engine. Conventional cooling is used.

With VarioDrive

Like the larger models, the 600 Vario features VarioDrive transmission and a new TA150 version of the gearbox has been developed for the smaller tractors. Using one pump supplying oil to two separate drive motors, it automatically adjusts power distribution between the front and rear axles, and 4wd is automatically engaged whenever it provides an advantage.

A single operating speed range from 0–50kph means there is no need for users to select field or transport working modes, and at higher road speeds the drive to the front wheels completely disconnects to avoid losses through the system.

A benefit of delivering drive independently to the front and rear axles is that, during tight turns, the front wheels can be accelerated to pull the tractor around in the steering direction. The result is an incredibly tight turning radius

of only 10.2m on 540/65R30 front tyres.

The system also avoids front wheel lead issues as the speed of each axle is matched, whether turning or travelling in a straight line. Tyre wear is reduced and less power and fuel are wasted, especially during loader operations on hard surfaces.

The 600 Vario models can be ballasted to 13.5t. Standard wheel and tyre equipment includes 650/65R42 tyres at the rear and 540/65R30 at the front. Maximum hydraulic flow of 205 litres is available as well as power beyond.

Lightweight and versatile

The 600 Vario models all share a 2.72m wheelbase – 6cm shorter than the 700 Vario Gen 6, and the same as the older 820 Vario. With a front linkage and PTO, the 600 Vario models weigh 7.7t unladen, but have an impressive 13.5t gross vehicle weight allowing them to be heavily ballasted for maximum traction to make the most of the impressive pulling capability, or to carry large implements including high-capacity spreaders and sprayers.

Standard tyres are 650/65R42 at the rear and 540/65R30 at the front. Fendt VarioGrip central tyre inflation is an option, capable of inflating the tyres by 1Bar in under five minutes. Ed commented that it wasn’t previously an option for mid-sized models, but that 80% of 800 Vario and 900 Vario tractors sold in recent years have been specified with the system.

Impressive hydraulics

The new models boast impressive hydraulic capability. The standard pump supplies 152 litres/min, but an optional upgrade to 205 litres/min is available. A maximum of five hydraulic spools can be specified at the rear and power-beyond is an option.

Like the new 700 Vario Gen7 models, the new 600 Vario can be equipped with a dedicated valve block with three oil supply outlets for the front loader, leaving other valves available for implements. Two additional spools can be fitted at the front. Capability to tip large trailers and work with complex implements is ensured with up to 65 litres of oil available for use off-board.

New front loaders

New front loaders have been added to the range for the 600 Vario tractors. The most powerful Fendt Cargo 5.90 loader lifts up to 3.46t and has a maximum lift height of 4.5m. It is available with a weighing function.

An optional 3L joystick can be added to operate the loader, enabling three hydraulic functions to be performed simultaneously – and making it especially suitable for silage grabs. It also includes shift buttons for forward and reverse, allowing loader and driving control using only one hand while the other operates the steering wheel.

Fendt also demonstrated a new optional steering joystick at the event. This mounts on an armrest on the left side of the driver’s seat and allows proportional and effortless steering from lock to lock by moving the handle from side to side.

FendtONE allows up to three terminals to be used simultaneously.

FendtONE cab

Fendt has equipped the 600 Vario series with the FendtONE operating concept. This was introduced on 700 Vario Gen6 tractors approximately four years ago and gives operators great flexibility in tailoring the controls and displays to suit personal preferences and the task. A multifunction joystick, 10in digital dashboard and a 12in touch terminal on the armrest are standard and an additional 12in drop-down touch terminal can be added in the cab roof on the right-hand side.

Almost any operating information including tractor settings and performance data, GPS field maps and Isobus-implement displays can be allocated to any of the screens, and there is also the option to show the same information on multiple screens or divide the screens into sections each displaying different images or data.

There is full compatibility with Fendt precision farming systems including Fendt Guide guidance, Fendt Section Control and Fendt Variable Rate Control, and Fendt Connect telematics are standard.

The FendtONE armrest provides plenty of opportunities for operators to set-up the controls to suit the task and their preferences.

Generous specification

The VisioPlus cab has Cat 2 air filtration as standard, and Cat 4 air filtration is an option. Like larger 700 Vario models, the new 600 Vario has a panoramic curved windscreen providing a clear view of the front loader at maximum height. The low, narrow bonnet allows a superb view to the front, including down to the wheels, and the standard front wiper has a 300-degree sweep area. An optional right-side window wiper sweeps 97 degrees for a clear view to the side.

The air conditioning system is significantly uprated and quoted cab noise levels of just 68db contribute to operator comfort. There is a choice of seats, including the top specification with integral heating and cooling, four-way lumbar support, adjustable side bolsters, massage functions and a memory – allowing saved user profiles to be stored and retrieved by selecting them on the touch-terminal.

Many 600 Vario tractors will be bought for loader work. A new Cargo 5.90 front loader has been designed specially, with 3.46t lift capacity and 4.5m maximum lift height. Load weighing is an option.

Test drive

The two tractors at the press event were the only two 600 Vario tractors manufactured so far in the finished guise, and one of these was due to be cleaned up after the test-drive and prepared for exhibiting on the stand at Agritechnica.

Both tractors were the most powerful 620 Vario model. One was equipped with the new Cargo 5.90 front loader, and the other was attached to a 4m cultivator.

The FendtONE cab is comfortable and well laid out. The top-specification seat with pneumatic suspension was fitted.

The 4m Kockerling Trio cultivator working stiff, dry ground allowed the tractor’s power and traction capabilities to be thoroughly tested. Using the hydraulic top-link, the implement working angle was easily adjusted to vary the working depth of the front row of tines.

A working speed of 9.7kph was set on the cruise control, and as the tines were forced progressively deeper, the engine note altered as the torque increased, but the 224hp 4-cyl tractor coped impressively and maintained the set speed without fuss.

The Kockerling 4m cultivator working hard, dry ground took a lot of pulling, but the 600 Vario had plenty of power and traction.

The FendtID low speed concept works well, and after each headland turn the engine speed rose as the working load increased, and then dropped back as the FendtID management system tuned the engine and transmission for maximum efficiency.

Visibility to the front is excellent through the panoramic curved screen. The dashboard display can show essential performance information, field maps, camera views or Isobus-connected implements.

At 9.7kph and with the tines pushed deep in the ground, the engine speed varied between 1,390–1,720rpm, and fuel consumption was approximately 37 litres/hour.

Headland turns were completed automatically, including steering to maximise working efficiency. An acoustic warning sounds as the headland boundary is approached and the intended turning direction is displayed on the screen. If this is acceptable, then the operator has nothing to do apart from monitor progress as the implement lifts and lowers automatically and pre-set speeds for working and turning are activated at the relevant times.

Even though the tractor was a pre-production, hand-built example, there were no vibrations or rattles and everything worked well. Monitoring noise levels during operation, the average was 68db, but with the climate control system turned off this reduced to 65–66db – very low for a hard-working 4-cyl tractor.

Testing the tractor at higher speeds up to 40kph on a concrete farm track, the front axle, cab and seat suspension performed well, and the tractor felt stable and secure.

Verdict

The new Fendt 600 Vario enters full production in July 2024, although orders will be taken following the Agritechnica launch.

Premium Fendt features such as VarioDrive are a big attraction, maximising performance, efficiency and productivity while also saving tyre wear and fuel. In terms of comfort, the cab is hard to beat and the FendtONE operating concept makes it a rewarding tractor to drive. Skilled operators have plenty of opportunity to tweak settings to get the most from the machine while those with less experience can utilise the user-friendly technology to help them operate effectively.

Many potential buyers will regard a 4-cyl engine producing 224hp with suspicion. However, after putting it through its paces and seeing how well it coped with the heavy draft load, it is hard to see how a 6-cyl tractor of similar power could offer advantages. The 4-cyl engine is smooth, quiet and economical and perfectly matched with the latest TA150 transmission.

Pictured with the new 620 Vario are (l-r) Ed Dennett, Oskar Dreyer and Simon Landgraf.

Farmers Guide also tested the optional steering joystick available for the 600 Vario series, fitted to one of Fendt’s larger tractors. Loading soil from a heap into a trailer, it saved time and effort compared to using the steering wheel and it is likely to prove particularly popular with those buying the tractors primarily for loader work.

FG Auctions, part of Fisher German, which has an office in Banbury, sold the 23-acre parcel off the Southam Road in Mollington for £376,035 after attracting 61 separate bids.

The owner of the land, which was previously used as grazing pasture, was unsure about its value after being approached by several people interested in buying it off-market.

He received several offers, which were very mixed and he was not sure if he was getting a good price for the land.

The owner contacted Fisher German’s Banbury office and was put in touch with Tom Dennes, head of online auctions at the firm.

Tom recommended the owner put the land up for auction instead of trying to sell it in the traditional way.

He said: “Putting the asset up for auction is the truest test of its actual value, and you’ll know that the buyer who really wants that asset will be prepared to pay a little more for it.

“This was clearly the case for our client in Mollington, who did not know if the offers he was receiving were actually fair.

“As he also didn’t want to choose one buyer over another for fear of upsetting people, we suggested putting it up for online auction and letting potential buyers bid for it.

“Once the auction began, it was clear that there were plenty of interested cash buyers who were willing to put good offers in to acquire it. After generating a lot of bids, it achieved far more than its £260,000 asking price, which was a brilliant result.”

Online auctions have increased in popularity at Fisher German in recent months due to its convenience and ability to produce a definitive outcome.

And while the traditional method of selling property through private treaty is still very popular, Tom believes online auctions are no longer being considered as a last resort.

“In cases like this where landowners have had parcels of land for a while that later need to be sold, it can often be prudent to consider an auction when the value of the land is difficult to estimate through private treaty,” Tom added.

“Buyers and vendors have told us they love the transparency of the dynamic online auction platform, with all offers visible and the certainty of a sale once the reserve price has been met.

“We would encourage any landowner who is unsure about the value of their land to contact us, and we can advise on the best method to achieve the highest price.”

Köckerling produces a wide range of cultivators, disc harrows and seed drills to suit different soil types and conditions. Its cultivator range has a reputation for long life and low running costs.

Every cultivator in the range has been manufactured to exacting standards using hot drawn box sections as standard; hence the enviable reputation Köckerling now has for long working life, low running cost, and versatile machines, the company explains.

The range of cultivators includes both trailed and mounted versions that are all fitted with the original double STS roller.

The Allrounder Profiline with its four rows of tines spaced at 16.7cm is capable of a number of different tasks, including seedbed preparation after ploughing, opening soil for quicker drying, secondary stubble cultivations, and as a primary cultivator in lighter conditions.

The Allrounder Flatline is equipped with heavy-duty double sprung elephant tines spaced at 130mm over six rows. This machine can work from very shallow or to a depth of 13cm.

The Vario is the flagship of the Köckerling fleet and comes as standard with full hydraulic depth control with 13cm tine spacing over eight rows. The soil and crop residue are carried in the machine for a number of meters to give optimum mix and distribution of crop residue to leave a perfectly level finish in just one pass.

Other cultivators in the range include the Quadro and Vector aimed at deeper working and the Rebell short disc harrow.

Shop used cultivators and tillage equipment at FarmAds.

Excellent dealer back-up and a preference for AGCO products convinced Norfolk-based farm manager, James Brown to invest in its first Fendt Rogator 655 self-propelled sprayer.

South Pickenham Estate near Swaffham, Norfolk, comprises approximately 3,000ha of owned land, most of which is farmed in-hand by farm manager James Brown and his team. Some 600ha is rented out, mainly for carrot, onion and potato production which helps provide an extended rotation. Most of the soils are light, but there are areas of heavier land further north. Irrigation is available for vegetables but can also be used on the farm’s own crops which include winter wheat, winter barley, oilseed rape, sugar beet, winter beans and maize for a local AD plant.

The farm recently invested in its first Fendt Rogator 655 self-propelled sprayer following demonstrations of the Fendt, plus three competitor machines.

“We always shop around, and the price and specification are major factors,” explained James. “We tried the latest version of the sprayer we owned previously, and two others. As we expected, they all had good and bad points, but part of the Rogator’s appeal is that it is a premium product which shares the cab layout and operating logic with our Fendt tractors, so it is home from home for operators moving between tractor operations and spraying.”

Increased work rates

Previous spray systems included a pair of 4,000-litre sprayers, one self-propelled and one trailed, with 32m booms. In 2015, a single 6,000-litre, self-propelled sprayer was purchased and, at the same time, the farm changed to a 36m spray width. The new Rogator 655 also has a 6,000-litre tank and 36m booms but, with superior ride suspension, as well as extremely effective boom suspension and height control, it achieves higher work rates and is expected to complete the annual spraying workload in 1,000–1,200 operating hours per year.

As well as spraying crop treatments, the Rogator also applies fertiliser. “We use liquid fertilisers throughout the year, except for the last dose when we apply granules instead. This helps us avoid risks of flag leaf scorch and reduces pressure on the sprayer when fungicide applications are the priority,” said James.

Improved accuracy and spray efficacy

The farm’s previous sprayer had spray control in three metre sections, but the new Rogator has individual nozzle shut-off and QuadSelect nozzle bodies which each have four nozzles. The optimum nozzle or two-nozzle combination is automatically selected to maintain the ideal droplet size while application rates adjust relative to travel speed. “We immediately saw an improvement because of the individual nozzle control,” said James. “Spraying around obstructions; there used to be triangular chunks where overlaps or misses occurred, but now we have perfect circles and more consistent crops.”

Adjustable wheel track

The Fendt Rogator came with OptiRide hydro-pneumatic suspension which allows the machine height to be raised by up to 45cm, giving 120cm under machine clearance for working in tall crops including maize and oilseed rape. It was also specified with OptiTrack hydraulic-adjustable track width which allows the wheel spacing to be altered between 1.80–2.25m from the cab. James explained that an alternative option would have been to change the track width used in the farm’s cereal crops to match the sugar beet and maize, and save money by purchasing the sprayer with standard fixed axles. However, he believes that the convenient adjustment gives the farm additional options for the future and will also allow the Rogator’s use for applications to vegetable crops grown by the farm’s tenants, if needed.

There are two sets of wheels for the sprayer. Wider flotation tyres are used on stubbles and during the early growth stages. Later – narrow wheels are fitted to reduce crop damage. The Rogator’s wheels are 2.05m diameter, and this means that even on the narrow row crops there is still a large footprint, and the sprayer travels well on soft, wet ground.

AGCO telemetry

Like the farm’s AGCO tractors, the Fendt Rogator sprayer has telemetry as standard. “Using the AGCO Connect smartphone app: we can view the locations and work status of all the tractors and the sprayer in real-time,” commented James. “It’s a definite advantage of operating machines which are all from the AGCO family. The app is a useful management tool and being able to monitor task progress remotely helps us plan our activities.

“The TNS workshop team uses it too. The diagnostics function allows technicians to check remotely for errors and, if a visit to the farm is needed, then the engineers can check the machine’s location. AGCO Connect is reassuring when it comes to operator safety; particularly if people are working alone. If we can’t contact an operator, we can check whether the machine is still working, or see if it has returned to the yard.”

South Pickenham Estate farm manager, James Brown with sprayer operator, David Dye.

Best cab on the market

David Dye is the sprayer’s main operator. “I believe the Rogator’s VisionCab is the best on the market, but it’s a Fendt so that is expected,” he said. “The ride quality and comfort are very good. Even with a full load, the engine runs at only 1,200rpm so it’s particularly quiet. It’s a pleasant place to spend the day.”

David describes the tank filling system as excellent, and he likes the large 60-litre induction hopper which handles two bags of powder at a time with ease. “I usually set the automatic tank filling system to stop early, giving me time to add the chemicals before topping up with water,” he explained. “The pause function is handy for filling fertiliser too. We use a 3in hose, and the 785 litres/min pump fills the tank in just over five minutes.”

The automatic boom height control system is reliable although it can be over-sensitive to crop density which means it drops in areas of thinner crop. “It is very reactive, but even where crops are uneven, the automatic mode works well,” he stressed.

Work rates

Average work rates are approximately 180–210ha per day. “It achieves that very easily, even though many of our fields are quite small,” David continued. “It’s got everything I need to do a good job and allows me to take pride in the results.”

Dealer back-up key to buying decision

The farm’s current tractor fleet includes five AGCO brand tractors, three of which are Fendts. They were all supplied and are looked after by the TNS team. “The tractors perform well, operators like them and they are reliable,” James stressed, “but we still wouldn’t consider them without effective back-up. Area sales manager, Jolly Bullen is based at the Attleborough depot. He’s our main sales contact and always friendly and helpful. He’s familiar with our business and knows what we need. The workshop team at Attleborough have looked after our AGCO tractors for many years and are excellent. The sprayer specialists, Gareth Bell and Ben Miller are based further away at the Littleport depot, but when help is needed they are always available by phone and use their experience as well as remote access to the sprayer’s telemetry to resolve issues quickly. The Rogator has been almost totally reliable since it arrived in January, but we know that even if something major goes wrong, we won’t be without the machine for long.”

Fast charging

The machine boasts the largest standard battery pack in its class, with 20kWh capacity, JCB says.

The 403E has a built-in charger that allows connection to a range of on-site power sources. A 110V socket will fully charge batteries in 12 hours, while a 230V industrial or domestic plug will charge in eight hours. JCB’s off-board rapid charger delivers a full charge from a three-phase supply in just two hours.

Electric motors with three driving modes

The machine is equipped with two independent electric motors, one for the driveline and one for the hydraulics. The drive motor offers 33.4kW of power and comes with three driving modes, that the operator can toggle between using two buttons on top of the joystick.

Drive is transmitted through an integrated drop-box to ZF axles that can be supplied with open differentials or with differential locks for maximum traction. The loader is offered with a choice of narrow or wide wheels, plus the option of agricultural or industrial tyres.

Standard or high-lift arm configurations

The loader arms are available in standard and high-lift configurations. The standard lift arms deliver a pin height of 2.9m, while the high-lift model achieves a 3.1m pin height. Both loader arm set-ups come with a hydraulic quick hitch as standard and the loader arms provide true parallel lift.

Tipping load provides versatility

The 403E offers a tipping load of 972kg with pallet forks, within a transport weight of just 2,671kg. This makes it an ideal machine for use on farms with more than one set of buildings, as well as for contracting, landscaping, fencing and other related activities, according to JCB. A heavy-duty counterweight is available as an option, increasing the tipping load by 118kg and the transport weight by 121kg.

Dynamic response and precision control

The machine has a 20kW high efficiency hydraulic pump motor and the hydraulic system offers two operating modes, controlled by a rocker switch on the main console. Shovel/bucket mode provides dynamic response, while the fork mode delivers increased precision control. A programmable constant flow auxiliary feature is also standard, to power motorised attachments such as bedding spreaders used in cubicle houses or open yards, hay and silage bale processors, and yard sweepers, with the operator setting the flow rate through the main display and rotary controller.

An impressive machine

The 403E is offered with a fixed or folding canopy initially, with a fully glazed cab as an alternative from Q3 in 2023.

The machine has a single joystick with a proportional auxiliary controller on top. An optional second auxiliary roller can be provided, allowing the operator to access all loader functions from one lever.

There is a new multifunction digital display, controlled by the rotary controller to the right of the loader joystick. The operator can use the rotary controller to set auxiliary hydraulic flow rates, inching travel speeds and other settings within the display. The monitor also provides all critical machine operating data, including driving mode, state of battery charge and travel speed.

Shop used loaders and other materials handlers for sale on FarmAds.

Case IH has extended its Optum range with a new 340hp model that promises enhanced performance, durability and reliability, as well as a new cab and telematics and connect packages.

Despite multiple improvements, Case IH says the Optum 340 CVXDrive with AFS ConnectTM is no heavier than the existing 300 and 270 models, but provides more power, ultimate productivity, and the ability to handle any task. It caters for the growing market for multi-purpose, high power tractors, maximising the Optum concept of high power, low weight tractors that can be ballasted as required.

It’s ideal for draft and PTO applications, from tillage and seeding to mowing and transport, the manufacturer reckons, and it has one of the quietest cabs on the market.

Features include:

- 6-cyl, 6.7-litre stage 5 FPT engine

- Hi-eSCR2 emissions reduction technology

- Automatic Productivity Management

- An upgraded CVXDrive transmission which incorporates improvements to the hydrostatic unit and control software, driveline components, rear differential, and rear PTO

- A new external engine blow-by filter to reduce service time

- 630-litre fuel tank and 750-hour engine service schedule.

New high power range

To increase versatility and compatibility in daily operations, the standard Isobus Class 3 can be upgraded to Tractor Implement Management (TIM), the latest tractor-implement communications protocol, so that certified implements can automatically control specific tractor functions.

The new model offers 27hp, or 9%, more power than the Optum 300 CVXDrive, while peak torque is 1,398Nm at 1,400rpm, compared with 1,282Nm at the same speed for its smaller stablemate.

The powerful rear linkage which can lift 11,058kg, a front linkage with a maximum capacity of 6,016kg, and two-speed front and four-speed rear PTOs further enhance the tractor’s versatility.

More room, more functionality

Features of the new spacious cab include excellent all-round visibility and a key fob for keyless operation, Case IH says. The redesigned ergonomic Multicontroller armrest puts 95% of the most-used functions at the driver’s fingertips, many of which can be operated either via the touchscreen or new integrated turn-and-press encoder dial. For ultimate operating and ride comfort, an optional new semi active cab suspension can be chosen.

Advanced technologies

The new AFS Pro 1200 touchscreen monitor with Bluetooth functionality gives an overview of all tractor functions. It helps the operator optimise engine, transmission, hydraulic and PTO performance, while also managing the operation of the implements. The new AFS Vision Pro operating system enables precision farming functionality, tractor systems and connectivity to match the required operating preferences.

An array of advanced technologies available only from Case IH are also included, such as a five-year subscription to the AFS Connect advanced telematics portal which enables remote monitoring and management of farm, fleet, and data. It also comes with Safeguard Connect, a comprehensive package of value-added services, and a three-year subscription to Case IH MaxService, which operates around the clock during peak season in partnership with the dealer network to maximise machine uptime. Finally, pre-season checks, pro-active support and training is provided.

Take a look at the second-hand tractors for sale at FarmAds.

Opico have launched a new version of its He-Va Combi-Disc at the Cereals Event held earlier this year in June.

The ‘Stealth’ variant of the ever-popular combination cultivator gains ultra-low disturbance legs and a choice of different points depending on the level of sub-surface action required.

Soil-engaging elements for adaptability

Now available in working widths from 2.45–5.25m in both mounted and trailed formats, the Combi-Disc employs two leading rows of soil-loosening legs followed by two rows of serrated Sabre discs to provide a surface chopping and mixing effect. This is all followed up with a V-profile roller to produce a corrugated, weather-proof finish.

It is this combination of soil-engaging elements that makes the Combi-Disc such an adaptable tool. In normal circumstances the tines, discs and press are used in partnership to turn previously uncultivated ground into a seedbed in one pass. When conditions require it, the discs can be lifted completely out of work, enabling the unit to be used as a straightforward subsoil loosener/pan-buster.

Versatility at its best

Likewise, with the legs lifted out of contention, the machine can be put to work as a straightforward shallow disc cultivator.

The addition of new ‘Stealth’ soil-loosening legs add further to the Combi-Disc’s versatility, making it a true low disturbance subsoiler with the added ability of being able to provide some surface tilth creation at the same time.

“With the increased focus on regenerative practices, we’re seeing a need for cultivation kit that can reduce soil disturbance but still deal with compacted layers in the soil profile to ensure decent drainage and rooting to maximise crop potential,” explains Opico’s He-Va product manager, Glenn Bootman.

“With this new leg option for the Combi-Disc, we are answering that requirement. The basic principle is medium-depth, low disturbance soil loosening combined with shallow surface cultivation. I believe that now makes the Combi-Disc one of the most adaptable tillage tools on the market.”

Deep soil loosening with minimal surface disturbance

The 15mm wide Stealth low disturbance leg and low disturbance point are the product of many years of development. Whilst large numbers of growers are now moving towards reduced tillage systems, they appreciate that drainage is key to crop development, allowing timely field operations and preventing the relentless progress of grass weeds such as blackgrass. The Stealth leg and point that He-Va has developed allows deep soil loosening whilst minimising surface disturbance and preventing mixing of the soil profile.The narrower legs are made from ultra-strong Hardox steel and can be interchanged with standard 25mm wide subsoiler legs as necessary. However, it is the point that really makes the difference. The Stealth standard 120mm low disturbance point has a shallower wing angle and shorter nose that has been designed to open up the soil to create drainage fissuring without mixing the whole soil profile.

Those wanting increased soil loosening across a wider profile can opt for a wider 200mm point. Both widths are available with and without long-life tungsten facing.

Shop second-hand cultivators at FarmAds.

Kuhn’s new high-capacity trailed sprayer

The Lexis is compact and lightweight despite its ability to carry 4,000 litres. It has a maximum length of 6.9m and an overall width of 2.55m. Featuring aluminium booms up to 28m, the Lexis still has an unladen weight of just over 3 tonnes. The latest model also features new 1.85m tyres with a very high flexion (VF) option from 320–520mm which will help to reduce compaction and protect soil health.

The Lexis can be specified with Kuhn’s Manuset manual rinse operation which only requires two main valves that are controlled from the operator’s control station. Multifunction handwheels reduce handling operations by up to 50% and the ergonomic design means valves are easily operated for a simple, trouble-free set-up.

During rinsing, a complete turn with the delivery circuit handwheel ensures that the water drawn in by the pump is conveyed into all sprayer circuits. The rinsing tank level gauge, visible from the workstation, also enables easy sequencing of the rinsing operations.

The new Lexis is also available with Diluset+ which offers operators assisted management of filling and dilution of residual volumes.

Spraying with the Lexis can be operated using Kuhn’s Canbus control box, a CCI 800 or 1200, or

any other Isobus terminal.

The Lexis is stable and manoeuvrable because the shape of its tank has lowered the centre of gravity. This improves stability, even with a reduced track width of 1.5m or when spraying on gradients. The short tow eye-axle distance of 4.30m coupled with the Track Assist gyroscopic steering drawbar system also improves tracking in the tractor wheels.

The Lexis can be fitted with CCE individual nozzle control, Autospray PWM technology or the Boom Assist Extreme contour control system. Kuhn’s CCI Connect solutions and MyKUHN portal also provide remote access to the machine and feedback on the tasks performed to harness valuable operational and application data.