Michael Tomlinson has been hedge cutting since 1982, operating from near Uttoxeter and serving a wide range of agricultural and rural clients in Staffordshire, Derbyshire and Warwickshire.

Usually starting the hedge trimming process from July, through to the following March, his company works on all kinds of hedging styles and types, so they need the right equipment. In the past, Michael’s company had been using solely flail hedge cutting units to deal with typical hawthorn hedging on farms and evergreens in the rural suburbs.

“Using a flail hedge cutter head on typical thorn hedges is fine,” said Michael, “but on many of the evergreen hedges, it’s not good. We found that the draft coming from the flails rotating would cause the tips of the hedges to blow away from the blades and it was often difficult to maintain a straight, neat cut. Also, it would leave large clumps of un-mulched clippings that would collect and leave an unsightly mess. So, we had to do something about improving our service because it needs to be a professional finish, every time.”

Michael heard that a hedge cutter unit was being launched by Major Equipment, a company well known for manufacturing high-end mowers capable of handling the roughest and toughest of work environments. He tried a demo unit from dealer G Richardson Agri Ltd, in Cheshire, on his Shelbourne Reynolds HD 865 VFRT.

“It was just a matter of removing the flail head and re-attaching the Major rotary head. What I immediately found was that it required much less oil flow to the head drive and therefore much less engine power, and would likely reduce my fuel costs,” Michael explained.

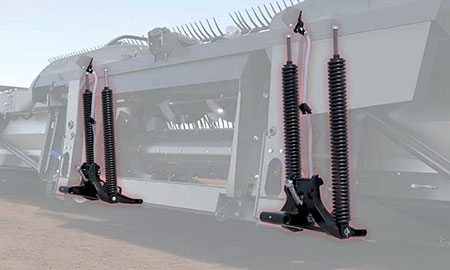

Major’s 1.43m hedge cutter head, fits directly to most hedge cutter arms on the market without modifications. It has a total head width of 1.6m and a cutting width of 1.43m. It only requires around 36hp to drive and an oil flow of just 80 litres per minute at a maximum of 170-bar pressure. The Major Hedge Cutter comes fully galvanised for long life protection against corrosion.

“Once we started using this new Major hedge cutting head, we calculated that compared with our flail heads, we were saving around £100 per week on fuel costs alone, purely because it was so much easier to drive. It mulched the evergreen clippings about the same as a flail head, but taking into consideration the fuel savings alone, on an annual basis, we are saving as much money that would buy the equivalent of another Major hedge cutter head for free, and that’s impressive!”

For more information, contact Major Equipment directly or visit the Major Equipment website

View FarmAds forestry and hedging equipment for sale

VJ Thomas & Son has invested in its slurry systems as its dairy herd has expanded. The 1,011ha operation is run from Pancross Farm, near Cardiff airport, and includes both grassland and arable crops. A slurry separator and a 500kW biodigester have been installed to provide a liquid slurry that is pumped through a series of underground pipes to enable umbilical application on almost all of the farm’s fields.

“We make sure everything we apply is less than 3% dry matter. This enables us to pump it through five miles of underground pipes to hydrants where we can hook up the umbilical kit and apply it using our 24m Vogelsang dribble bar systems,” explains farm manager, Chris Hanks.

Managed on-farm

The slurry is tested on-farm using an Agros testing kit, and three times a year a sample is sent to Lancrop for greater analysis.

“We have been managing the whole process on farm, with help from our agronomist David Llewellyn, for three years. As the farm has grown it has become ever more important that we are agile too. Being coastal, our weather windows can be short and unpredictable so when conditions allow we need to be at full capacity straight away,” Chris says.

The land is split, with 324ha acres set aside for silage, 243ha for maize, 405ha for wheat and the remainder planted with either spring barley or stubble turnips.

“We put two applications of slurry on the wheat crop. The maize has one application pre-emergence and another at three-leaf stage. We apply to the grassland before first and second cut too, so spring can be a really busy period,” he comments.

The farm operates a min-till system and manages all field work apart from maize planting on-farm with a dedicated team operating a fleet of John Deere tractors. With four lagoons, the underground pipe system, four 4,000-gallon tankers, and two Winbag nurse tanks, slurry can be moved around fields quickly and efficiently.

Investing in infrastructure

“Setting up and investing in the infrastructure has been a challenge, but we have the right equipment now and it is working well. We tried using trailing shoe applicators, but the stony ground meant that the shoes were pulling up stones that were then a nuisance when mowing. The volume through the Vogelsang dribble bars is also better and it helps that our slurry has such a low dry matter,” says Chris.

“We have two people teams and two tractors. Both dribble systems are 24m wide. The latest Vogelsang BackPac is lightweight, which reduces soil compaction and has a headland management system so we are only applying slurry where it is needed,” he explains.

Vogelsang’s BackPac design is centrally mounted on the tractor to reduce movement and improve accuracy. The arms fold quickly and neatly behind the tractor to make access to tighter spaces easier for operators.

Forage production

Forage production is a major concern for the farm which operates a multi cut silage system from which the first cut is fed to high yielding cows all year round. Subsequent cuts are clamped separately and fed to lower yielding, dry cows and youngstock.

“First cut is really important to us. We use an Italian rye mix and graze the leys with sheep over winter. We start by N-Min testing silage ground, then apply slurry and some fertiliser to top up the soil nutrients that can be made plant available,” he says.

Following this, and three to four weeks before harvesting the first cut, the farm uses SmartGrass to boost the gibberellic acid (GA3) which increases the cell wall thickness of the plant.

“The last application is Physiocrop, which provides additional amino acids to the grass to mitigate against stress,” he adds.

“We have a John Deere forager with Harvest Lab that provides us with data to help maximise protein, dry matter and yield. From this we have been able to utilise slurry more efficiently and manage our input costs more carefully too,” he says.

Applying slurry at varying times for the crops in the rotation has an added benefit of making best use of the farm’s tractor fleet and its workforce. Having brought slurry management back to the farm, Chris is convinced that it has been an agronomic and operational benefit to the whole business.

“Slurry application provides vital hours of work for our staff and makes better use of the fleet too. Having the best applicators helps us to make best use of a valuable natural resource, and the applicator technology is distributing it to the soil where it can be absorbed and its nutrients made available to the crop,” he says.

Wales has not seen the same grants made available for slurry management as England, which is currently benefiting from both the Slurry Infrastructure Grants and the Farming Equipment and Technology Fund (FETF).

“We have made our own investments, which have been significant but thoroughly worthwhile. Taking responsibility for slurry management and application has been a steep learning curve but it has reduced our costs and is improving our soils,” concludes Chris.

View FarmAds muck and slurry equipment for sale

Referring to itself as a leader in tackling grower challenges with innovative crop sprayers and cutting-edge technologies, Agrifac has introduced the final piece of the Condor product range puzzle; the Condor Vanguard – ready for the future and compliant with all European regulations.

With a tank capacity of 6,000 litres, a maximum vehicle width of 255cm and a driving speed of up to 50kph, Agrifac says the Condor Vanguard gives the market exactly what it needs. It can be used flexibly thanks to a 75cm adjustable track width and is available in two variants of track widths: 180–300cm.

More high-quality yield is achieved more efficiently, due to the fast filling, fast cleaning technology and fast folding booms. Not forgetting the most stable boom, this machine with higher capacity is the basis for optimum coverage and minimal drift. Like all self-propelled sprayers available from Agrifac, the Condor Vanguard is equipped with the most innovative and high-quality options, which takes it into the Vanguard of precision farming, specifically treating the crop at plant level.

Discover the latest developments from Agrifac, including advancements in spot spraying solutions thanks to intelligent integrated artificial intelligence cameras, by visiting the Agrifac website.

View FarmAds crop sprayers for sale

Apart from the proven six and eight-row variants with row spacings of 70–80cm, the new Azurit also comes with six or 12 rows with a 50cm row spacing. A furrow former has been added to the seeding coulters to improve the quality of seed placement. The drill pipe has been updated and now comes with an inlet that can be replaced once worn.

From the coming season, the range of applications of the Azurit 10 comprises not only the previous crops, but also soybeans and sunflowers. Another new feature is automatic seed singling for maize with a system that monitors and adjusts the quality of seed singling. This system can be retrofitted to older machines. A new fertiliser monitoring system in the Azurit 10 automatically alerts the operator if individual fertiliser coulters become blocked.

With the MicroHub 5, a spreader unit which allows microgranule to be applied in the direct vicinity of seeds, Lemken also offers yet another advantage for the Azurit 10. Microgranules contain water-soluble nutrients, which are rapidly available to plants and therefore generally produce excellent juvenile crop development. This is particularly important in cold, dry spring seasons. The initial nutrient needs of crops can be easily covered by relatively small amounts of microgranules.

Lemken says it deliberately shines a spotlight on fertiliser efficiency with the MicroHub 5, as this topic is gaining increased relevance in public discussions. “We offer this option for our Azurit with up to eight rows,” says Lemken’s head of design for precision seed drill technology, Bernd Valtwies. “This unit is not only available for new machines. Depending on the year of manufacture of previous Azurit 9 machines, matching retrofit kits will be available. The system is controlled via the Azurit on-board terminal. The MicroHub holds 200 litres of fertiliser, which can currently be applied at rates ranging from 1–40kg per hectare. The metering unit is operated electrically, and granules are pneumatically delivered to the seed furrow. This is the ultimate in precision,” points out Mr Valtwies.

Visit the Lemken website for more information.

View FarmAds seed drills for sale

Gareth Jones from Avon Tuning HD says that for jobs that don’t require a PTO, such as cultivations and trailer work, this is returning some real-world fuel savings by increasing the efficiency of the application.

“If a tractor achieves peak power at 2,000rpm, it must always be operating at its limit to achieve it. By changing certain parameters in the ECU, we can bring the peak power delivery to 1,600rpm, meaning the tractor doesn’t have to work as hard to achieve the same output and fuel savings can be achieved.”

By matching output to certain applications, Avon Tuning HD says it can safely improve performance within the engine’s capabilities. When applying an economy specific remap, Avon only adjusts key parameters such as fuel injection and torque limitation in the mid- and low-range, therefore top-end rpm performance is not changed.

These changes allow operators to run in a higher gear at lower revs to benefit from the additional low-down peak power. “This is noticed when ploughing or cultivating, especially if the implement has forced the tractor to work consistently at its limit before a remap. Fuel savings of between 5% and 10% are achievable in some situations,” says Gareth.

Before applying any remap, the tractor’s characteristics are cross-referenced to make sure any increase in power can be handled by all the component parts.

Visit the Avon Tuning HD website for more information

View FarmAds tractors for sale

The new VB 3260 and VB 3290 models replace the VB 3100 series (VB 3160 and VB 3190). Along with increased capacity, the new models feature Progressive Density Plus to achieve 10% higher bale density. The VB 3260 can produce bale sizes from 0.8–1.6m, whereas the VB 3290 can reach bale diameters of 1.85m.

Kuhn’s grassland product specialist, Rhodri Jenkins, said Kuhn has incorporated proven concepts from the outgoing models into the new design, and added innovative features to increase output and bale quality. “The range is aimed at customers requiring higher density bales and greater output in a variety of different crops throughout the season.”

A new heavy crop roller, with spring loaded tines for improved pre compression and crop flow, can increase overall efficiency of the baler by 10% compared with the previous generation. A quicker tailgate ejects a bale in six seconds.

The Progressive Density Plus system is a pressure boost to provide higher bale density in dry crops. The baler can be operated via a tractor’s Isobus terminal, or through the VTI 60, CCI 800 or CCI 1200 Isobus screens. Non-Isobus machines are standard with the VT 30 control unit.

A reinforced driveline for improved longevity includes a stronger main drive chain, larger rotor drive chain, and additional reinforced bearings and seals for the high-capacity rollers. Users have the option of a non-cutting Optifeed rotor to provide an even swath flow as it enters the baler, for consistent bales. A 14- and 23-knife Opticut rotor, with each knife spring protected against foreign objects and providing a theoretical chop length of 70mm for OC 14 and 45mm for the OC 23, is also available. Both Optifeed and Opticut models benefit from an Integral Rotor, offering greater throughput thanks to a shorter distance between the rotor and pick up tines to provide consistent crop flow. As standard on both models is the Dropfloor, allowing the floor and knives to be lowered hydraulically to clear blockages.

The 3260 and 3290 models are also available in baler-wrapper combination units with the same new features as standard models. Offering 15% quicker bale transfer times, the VBP 3260 and VBP 3290 are also equipped with automatic unloading of straw bales in pairs and a hold-to-run button for the satellite wrapper rotation.

The hold-to-run button allows operators to rotate the wrapping arms by half a revolution to ensure the wrap is connected to the bale after fitting a new roll, while rotating the satellite arms allows film roles to be replaced from the same side. A new 3D Eco Wrapping system reduces the amount of film applied to the centre of the bale and ensures the bale edges are covered first to protect the most vulnerable parts of the bale.

Visit the Kuhn website for more information.

View FarmAds balers and baling equipment for sale

Part of Landquip’s success lies with Richard’s early decision to fit all arable machines with the world-renowned Pommier aluminium booms which rapidly became an important USP for the company. Renowned for their strength and reliability the aluminium boom provides incredible weight distribution and performance.

Back in the 80s

Landquip started by retro-fitting aluminium booms to give machines a new lease of life, a service still available to this day and applicable to any make of sprayer, not just their own models. To complement the boom’s performance, in-house designed boom suspension systems, height masts and back frames can also be supplied, with some customers preferring to buy only the components to carry out the work themselves.

Richard then quickly moved onto in-house designs of new British-built mounted and trailed sprayers. Often the farmer created their own wish-list which could be incorporated into a bespoke machine, the company being flexible and open to ideas, an ethos which continues to this day.

In the 90s

Landquip built the first demount sprayer for the Fastrac. JCB’s latest Icon model can accommodate a 2,500-litre rear Landquip sprayer, a 1,500 or 1,900-litre Vision front tank, and the latest Isobus technology to give the farmer a sophisticated, modern unit capable of high outputs and remarkable performance. The sprayer can be quickly demounted in 10–20 minutes, freeing up the Fastrac for other jobs on the farm.

During this decade Landquip’s trailed sprayers also moved on apace with tracking being installed and Pozi-flow recirculation with air switched nozzles being fitted as standard.

At this time Richard was joined by David Reeve, who has progressed through the company from those early days to now hold the role of operations director. David has a wealth of knowledge in his field of technical support and trouble-shooting.

Moving into the 21st century

Landquip continued to innovate with its in-house CAD chassis designs. The customer was able to choose from a Pommier heavy duty contractors’ bi-fold/gullwing boom or the newly designed tri-fold boom available in greater widths. During this time the InTrac trailed sprayer was introduced with numerous features fitted as standard and capacities from 3,600–6,000 litres, a machine which remains at the forefront of technology and design.

In addition to its core business of British-built mounted, demount, trailed and self-propelled crop sprayers, Landquip has moved with the times, keeping abreast of new ideas and developments.

Present day developments include:

- Fully integrated GPS systems allowing auto section switching and ultrasonic boom levelling

- Spray line air blow-out systems

- Flowtron advanced flow rate nozzle control system which can be operated in PWM (pulse width modulation) for multiple flow management across the boom, variable rate, and turn compensation

- A range of mounted and trailed Mist Atomizers for orchards, vineyards and poultry shed cleaning

- Amenity sprayers for football clubs and golf course turf treatment

- UTV and ATV quadbike sprayers up to 4m

- The Premiair air sleeve system designed to blow into and penetrate the crop, not only for arable spraying but also for bulbs, roses, and potatoes

- Landquip’s own design Umbrella liquid fertiliser nozzles for accurate, scorch-free application from 150–1,500 litres/ha

- Vision Nitro-Band application systems for liquid fertiliser placement whilst seeding

- The PowerTrac trailed driven axle sprayer available with 6,000, 7,000 or 8,000 litres, which has an integral high pressure hydraulic system producing 130hp drive to the rear wheels, and is equipped with HDC (Hill Descent Control).

Landquip offers a comprehensive range of sprayer components, for example, from the smallest hose-tail to pumps, electric controls, electro-hydraulic valves, hosing, and wearing parts such as ceramic nozzles, diaphragms etc., all available on next day delivery or to collect from its Suffolk premises.

Landquip engineers, many of whom have years of experience, are fully trained in all aspects of servicing, including NSTS certification.

The company’s in-house design service ensures Landquip continues to innovate and work on new ideas to advance your spraying applications and requirements. “If you need it, we will strive to come up with the answer,” says Richard, who remains as fully enthusiastic as he was back in 1984 when it all began. “I, and my team, are enormously grateful to those customers who have put their trust in Landquip both in the UK and overseas. We will endeavour to serve the farming industry for many more years.”

Send an email to sales@landquip.co.uk or visit the Landquip website for more information.

View FarmAds crop sprayers for sale

The Trans-Cap, Joskin’s all-purpose tipping trailer, has multiple benefits that make it a firm favourite – starting with its V-shaped open drawbar, attached on both sides of the chassis to increase stability, and with cross-springs for a smoother suspension. The narrow chassis allows for wider tires, reducing soil compaction.

Combined with Joskin’s roll-over bogie, a running gear using spring leaves connected to both axles on a central pivot point, this makes the trailer more comfortable to drive and easier to pull in tough conditions, thanks to its 240mm clearance and constant weight repartition, Joskin continues.

The narrow chassis houses a single tipping ram in a double-oscillating frame, ensuring maximum stability and smoother tipping.

The monocoque tapered body uses a single sheet of special high tensile steel for each side and for the floor, and is robot-welded to increase the quality and lifespan of the trailer.

Wider by 8cm at the rear, and combined with the high clearance hydraulic door, the transported material is unloaded quickly and without any constraints. All rams are equipped with check valves for added safety.

Trans-Caps Advantage series are in stock and at discounted prices.

Visit the Joskin website for more information

View FarmAds trailers for sale

Slurry from housed livestock contains valuable nutrients, phosphate and potash as well as a host of other things that should be recycled back to land in an environmentally sustainable manner.

Waste is created from cow manure and water and provides a fantastic, natural fertiliser that farmers can use to encourage the growth of grass and other crops. It can, however, create significant pollution to our water and air. Every livestock farm has to deal with waste and with the increasing focus on environmental impact, it’s key that it’s managed appropriately.

Enter the Harry West Dual spreader range of machines, designed as a steel container that holds farm manure and slurry securely while travelling to the spread site.

A steel door allows metered discharge when operated hydraulically left to right across the rear of the Dual Spreader’s output rotor.

The rotation of the output rotor forces the manure, under slung, against the machine’s sprung plate allowing the breakup of the material and gives a low trajectory across the field. This limits the muck from being caught airborne and gives a more even and controlled spread.

This operation provides a positive spread of up to 21m, giving excellent coverage on both grass and arable land.

Material is eased down internally onto the feed auger with a standard agitator plate (walking wall) along the full length of the steep sided spreader.

The feed auger pulls the material forward towards the rear of the tractor giving a safer operation and certainty when used on undulating and boggy land.

James Llewellyn, sales director said: “The Harry West Dual spreader has evolved over a number of years into the all-round spreader, working with all types of material in a safe and environmentally sustainable method.”

Please contact your nearest West dealer for further details.

View FarmAds muck and slurry equipment for sale

History of drapers

Turning the clocks back, even the earliest binders and harvesting machines used draper style feeding in the form of canvases for the benefits of heads-first feeding to the threshing unit. The practicality and maintenance of damp canvases though was one of the main causes of the shift towards auger headers. For smaller headers, the simple driveline and rigid frame provided a low-cost and functional approach to combine feeding.

Fast forward to 1986 with many technological advances in draper manufacturing and engineering, MacDon’s experience with swather draper headers generated demand to fit its rubber-belted swather header to combines. The cost and performance benefits of heads-first feeding were again realised and from there exploded the demand for combine draper headers in the American Midwest.

Multi-crop advantages

In a period of wet weather, drilling windows and harvest windows are shortened; both of which put pressure on the combine when it is most critically needed. Crop diversification is one solution to this challenge so long as the crop can be suitably harvested when ready.

The MacDon FD2 has been tested in practically every crop around the world, in pretty much every condition anyone would dare to put in front of it. In many scenarios, the combine header is known to be the limiting factor for combine throughput where lodged wheat or damp, dewy barley make for a very unpleasant harvesting experience. Having the draper feeding and the floating headstock make this significantly easier on the operator, giving the farm the confidence to plant a range of diverse crops and trusting that the header will not be the limiting factor at harvest time.

Floating linkage

The wet weather doesn’t just create pressure at drilling and harvest time though. The need to get fertiliser on early is notorious for leaving rutted tramlines which cause havoc with height-sensing combine headers at harvest. Having the header mounted on a floating linkage takes the stress out of navigating these, which MacDon says it has perfected since the release of the FlexDraper in 2004. The system works neatly in conjunction with the combine’s existing auto header height control system, but allows the combine to take a relaxed back-seat approach to ground following. The instant mechanical response means badger sets and tramline ruts are no longer a worry to the operator, and negate the downtime associated with changing knife sections.

Along with the floating linkage, the frame of the FlexDraper is split into three sections. Each of these follow the ground independently, allowing the header to work much closer to the ground where laid crop or short crops are nestled in valley bottoms or over ridges in the field. While this capability was developed with the terraced fields of the Midwest in mind, it has just as equally found a new home in the rolling vales and hills of the UK. Being able to cut all the crop without the need to cut at multiple angles means reduced field passes and an easier operator experience.

Integration

Just as the three-point linkage and Isobus has standardised the tractor implement side of the industry, MacDon says it is leading the way with ensuring seamless compatibility between combines and combine headers. By interfacing through the existing combine’s controls, the MacDon FD2 retains the functionality and features that one could expect from a combine manufacturer’s own header.

Knowing that the header can be adapted to a range of combine brands allows farmers to invest knowing that the header can be kept for multiple combines, regardless of whether the combine colour changes down the line. Not many will look back to the days when a plough and tractor were bought as a combined unit; the practicalities and benefits associated with the commonised three-point linkage really set the bar for justifying capital expenditure, allowing tractor and implement manufacturers to innovate and specialise separately in their particular area.

In an uncertain economic climate, there is a tendency to hold on to equipment longer and make purchases that have a more direct impact on business performance. While the FD2 will improve the productivity of the combine, the additional investment needs to be justified, the manufacturer acknowledges. The high serviceability and minimal regular maintenance of MacDon headers lends itself to a long service life, evidenced by many FlexDraper headers having done several thousands of hours. This longevity helps maintain the resale value and further reduces the cost of ownership. Retaining the header for multiple combines is a new concept to the European market but one that is firmly established in other markets, allowing equipment to earn its full potential rather than being traded prematurely.

The trend towards draper headers has been accelerated by the growth of farm businesses and the need to get more out of the combine at harvest. The MacDon FlexDraper has led the European charge in the shift to draper headers and continues to deliver on innovation and performance to ensure it can meet the demands of modern agriculture in challenging conditions.

Visit the MacDon website for more information

View FarmAds combine harvesters for sale