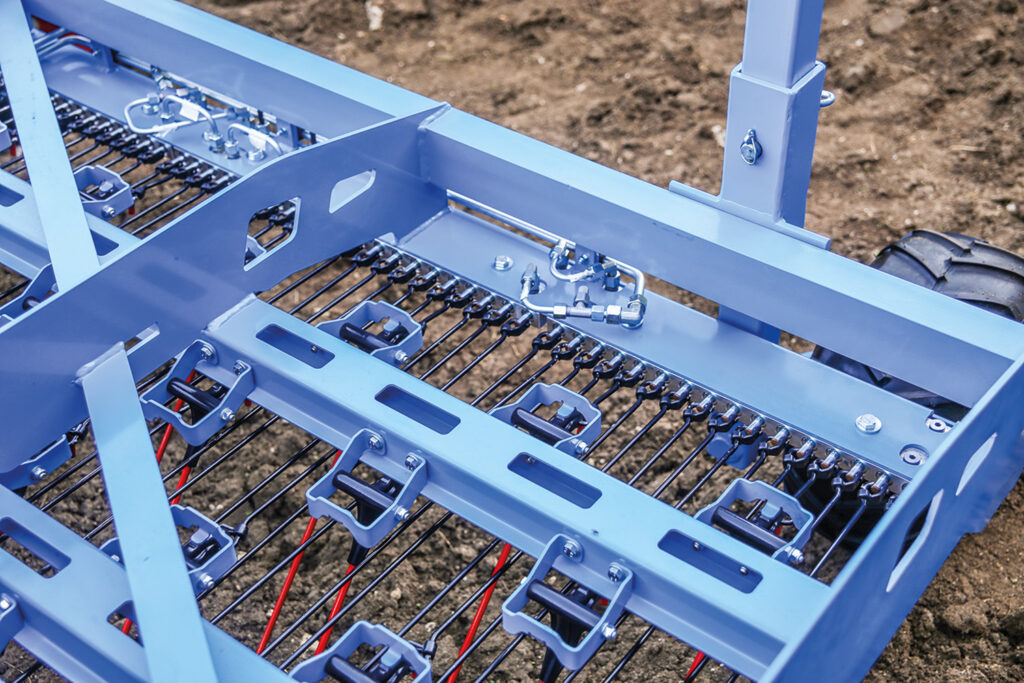

The company offers the renowned line of Simtech direct drills with its proven T-slot tines.

The drills are relatively simple, well-built, reliable and cost-effective, with minimal moving/wearing parts. These versatile machines will penetrate even very hard ground, while the renowned T-slot system creates a unique environment for the perfect seedling germination, even in the most demanding conditions. The drill range extends from 2.4m grass drills up to 6m folding arable drills.

Some of the new releases planned for 2024 include:

- New front-mounted hopper models to allow wider drilling using less horsepower and more balanced loading of the tractor

- A four-toolbar frame for users with high trash conditions or application into cover crops

- A trailed kit as an intermediate step from a fully mounted machine to a trailed machine

- A lightweight folding drill with no rear spring flex roller.

The company also offers ultra-low disturbance subsoiling products using Tillso tine technology, shallow annual or bi-annual restructuring by lifting and dropping the soil over a wing to create vertical fissures for better root establishment. The tine has been developed to create minimal surface disturbance, this reduces the need for following cultivations, prevents weed seeds from being dropped throughout the soil profile and keeps fine soil particles on the surface. The ‘Advantage’ is offered from 3–6m, in both mounted and trailed formats with various optional extras.

Another key tool in the shed is the ‘Commander’ – a shallow tine cultivator which promotes the production of stale seedbeds. The machine is offered in 6, 8, 10 and 12m widths, with optional vertical tillage discs.

The business model revolves around soil health and reduction of inputs. The aim is to achieve maximum yields without high input costs, while at the same time, improving the soils for the future.

The event opened with an address by Lemken company owner and board member, Nicola Lemken who is the seventh generation of the Lemken family to own and run the 243-year-old business.

Lemken CEO, Anthony van der Ley talked about recent sales performance and confirmed that the results for 2023 appear extremely positive, although his expectations for 2024 are for reduced sales due to European-wide higher interest rates.

Continued investment into products offering even better mechanical weed control includes plant-type recognition by camera using AI. Lemken has a solution for sugar beet growers, capable of recognising the crop from the two-leaf stage.

Investment in weeders

Lemken acquired mechanical weeding machinery specialist, Steketee in autumn 2018. Since the acquisition, Steketee production and sales volumes have tripled, to the extent that the current factory in the Netherlands has been outgrown. In spring 2024, machine production will transfer to a brand-new factory. The 5ha site will accommodate a 10,000m2 production area as well as an Agrofarm where products can be tested and demonstrated. The current manufacturer team of 60 staff will be doubled.

Until now, Steketee products have continued carrying their traditional branding including bright red paint, but from early next year the Lemken name and blue colour will be used instead. “The Steketee name is associated with expertise in this product area, but the Lemken name and colour is better known worldwide, so it makes sense to use these going forward, suggested Anthony. “Our target is to develop 20–25 new markets for the range throughout Europe and overseas.”

The new Thulit weed harrow is described as ‘third-generation’ by Lemken, for its ability to accurately maintain working pressure and depth even across undulating surfaces such as potato ridges. A 12m version will be available in 2025.

Continued investment

Recent developments in the Steketee product line-up includes new camera guidance technology combined with AI for increased suitability in a wider range of crops.

The IC Weeder which removes weeds using pivoting blades is expected to have strong appeal for sugar beet growers as improvements for 2024 will include plant recognition from just two true leaves, whereas current systems recognise the crop only from the four-leaf stage when hoe weed removal treatments are often too late. Lemken says the improved crop recognition capability allows 20% faster operating speed, and crop recognition accuracy of 95%.

Each Thulit tine is independently mounted on a durable plastic pivot, and working pressure is maintained using miniature hydraulic rams (one for every tine) within the implement frame.

Third-generation harrow

The Thulit spring harrow weeder is completely new. It consists of a bank of close-spaced sprung rake tines and its unique design ensures consistent operating pressure across all the tines regardless of whether some are working on top of ridges while others are in a furrow. This results in effective weed removal across the full working width, even on uneven ground. An adjustable tine angle allows operators to achieve the amount of aggression required. The tines are individually mounted on hinged brackets and connected by tension rods to separate miniature hydraulic rams. An accumulator helps maintain equal hydraulic pressure across the bank of cylinders, regardless of the number of tines in the raised or lowered positions. Lemken argues that the hydraulic pressure control system is simpler and more effective than complex spring arrangements.

The harrow operates by pulling small weeds out of the ground leaving roots exposed on the surface to dry out while other weeds are covered in soil preventing light interception. The spring rake tines aerate soils and break the top crust allowing moisture to penetrate while also levelling the surface.

The harrow is suitable for row crops, vegetables and ridged crops such as potatoes, and it is described by Lemken as a third generation weed hoe, because of its advanced design and ability to achieve the same operating pressure across all the tines no matter how uneven the ground.

The overall tine spacing is 31.25mm equivalent to 32 tines per metre. Lemken explained that mounting the tines across four rows allows large clearance between the tines within each row for trash and plants to flow through easily while achieving up to 97% effective weed control at a working speed of 8kph. Generous underbody clearance beneath the frame means blocking the harrow is almost impossible.

Thulit product specialist, Rik Aelfers is pictured with the new harrow, explaining that the very best weed control is achieved by tackling weeds as early as possible.

Simple set up

Two wheels front and rear control the working depth and the tine operating pressure is set hydraulically. Working pressure for each tine can be adjusted between 100–5,000g. When the working pressure is released, then the tines retract up into the frame achieving a narrower folded width for transport.

Only 50 of the Thulit 6 and 9m rakes will be available for next spring, and a 12m version will be launched in 2025 and is expected to eventually account for most sales.

The new Rubin 10, 10m compact disc harrow was demonstrated for the first time at the event.

New Rubin 10

During the press event, Lemken also demonstrated its brand-new Rubin 10 10m heavy disc cultivator for the first time in Europe, just a few days after its first public viewing at a show in the USA.

The new compact discs are the widest single units from Lemken so far, as achieving this width previously was only possible using two smaller sets mounted side-by-side on the Gigant tool carrier.

The 10m discs achieve high work rates while maintaining excellent ground contour following.

Effective results

The Rubin 10 has 645mm discs and, like smaller versions of the Rubin 10, these are arranged symmetrically to ensure a straight pull for fuel-efficient operation. The serrated concave discs are in two rows and ensure effective mixing and incorporation at shallow working depths down to only 7cm. The discs have an overall 14cm line spacing providing plenty of clearance for trash to follow through and each disc has individual overload compensation, with dampers reducing kick-back and preventing potential damage to the frame.

Hydraulic adjustment allows the working depth to be altered on the move from the cab.

The levelling tines are conveniently adjusted by hand from outside the implement frame ensuring maximum safety. The rear packer features new heavy-duty bearings designed to withstand the heavy working loads including carrying the discs when turning on headlands, and the discs are Lemken Duramaxx faced and 6mm thick for a long working life.

The discs fold to less than 3m wide, under 4m high and can be towed at speeds of up to 40kph.

Contour following

iQ-Contour pendulum-type suspension utilises an articulated chassis which allows the front and rear sections to move vertically. Up to 4.5 degrees of vertical downward movement and up to 6.0 degrees upward movement maintains excellent ground contour following, even across severe ground undulations.

Towing is by a drawbar eye or ball coupling and a hydraulic support ensures easy attachment to the tractor, while the hydraulic operated rear packer makes it easy to reverse the heavy discs into field corners and work around obstructions.

Nichola Lemken is pictured with Lemken CEO Anthony van der Ley at the first demonstration of the new 10m Rubin 10.

Deliveries for next autumn

Lemken said at the event that the Rubin 10 10m discs are the widest 645mm discs currently available and that they are designed for use with tractors from 350–500hp. The main design advantages include accurate depth control and ground contour following as well as exceptional convenience for transport, as the set folds to under 3m width and 4m high and is approved for towing at speeds up to 40kph.

Deliveries commence in time for next autumn cultivations and the price is approximately €170,000.

Look out for original tinwork

“Enthusiasts like tractors with genuine tinwork, in good condition; originality is very important – if I had to choose, I would rather buy something with good tinwork even if the engine doesn’t run. But I would rather a good engine if the tractor has rotted and rusted through, or the tinwork is missing – although reproduction tinwork has improved over the years,” he says.

Don’t be frightened if it doesn’t run

It is good to buy a tractor that runs well; check for engine back pressure and the breather pipe, which can indicate a worn engine. Although purchasers shouldn’t be put off if the tractor doesn’t run, check there aren’t any hidden problems. “For the Massey Ferguson 35 and 135, as well as the Fordson Dexta, check behind the injection pump for frost damage.”

It’s also important to check the parts match up. “The tractors I generally work with are Ford and Fordson, and they have codes on the castings, which say the day, month and year of manufacture. The gearbox, backend, engine, cylinder head and other castings are coded,” says Mr Duncan. “So if it’s a genuine tractor everything would match up, although parts of it might have sat for a month or so before assembly in the factory – but most of the castings would have been made within a few days of each other.”

Hydraulics are a common stumbling block. “It’s quite common on some Fords, Fordson Super Majors and Dextas that the hydraulics have stopped working, if the tractor has not been in use. It’s usually quite a simple fix like a stuck valve; people might think it’s going to be an expensive repair, but not necessarily.”

Get familiar with the tractor but exercise caution

Get familiar with the tractor but exercise caution

Check the brakes, water and oil levels throughout the tractor, he advises. “Don’t be too quick to drain the oil, it’s good to run the tractor first if possible and check for leaks, as well as brakes and hydraulics. “Safety is paramount. Make sure the handbrake or parking brake are working; commonly people will start the tractor while standing beside it – but it’s best to be sitting in the seat,” he warns. “Make sure the tractor is out of gear, with the brake on, as a lot of older tractors start in gear, which can be dangerous. “Ensure the PTO is disengaged, if it can be, and that there’s a guard on it. Some Massey Fergusons and Fords are known to have issues, where the PTO shafts won’t stop, even when they’re disengaged – which can be dangerous as well as expensive to repair.”

Don’t take it to pieces unnecessarily

If it has an oil leak, repair the leak, says Mr Duncan. “It doesn’t mean you have to completely overhaul the engine; sometimes people pull the engine, gearbox and backend to pieces when they don’t need to, then cause themselves a lot of unnecessary work and expense. “If the engine needs an overhaul then get the job done well; some makes and models are easier than others. Some have wet liners, like the Fordson Major and Nuffield range, which means you can pull the liners and fit new ones without going to an engine machinist. Some engines with dry liners need to be stripped down and sent to the machinist for a rebore, which is more expensive,” he adds.

“Some old tractors’ backends and gearboxes often go on for years and years. They might need new seals or bearings, but they’re made of good stuff. The British-made tractors, generally speaking – unless they’ve had a lot of neglect – are tough as old boots. The Fordson Major has the transmission hand brake which, if looked after, will last a lifetime, but if it has been driven with the brake on, this can cause damage.”

Do a bit at a time

Do a bit at a time

To fully restore a tractor is to get it back near to the condition when it came out of the factory. “Some people buy a vintage tractor and don’t do anything to it at all, but I think it is good to repair it when you have the time and money to do so. But sort out the mechanical problems before painting it,” says Mr Duncan.

“It’s good to do a bit of the tractor at a time and not completely strip everything down all at once. Always take photos of your tractor before strip down. If you are taking the engine apart, it’s good to check the timing gears and make sure that all the timing marks line up before taking them off. I have occasionally seen one of the gears a tooth out on the timing, so it’s good to get familiar with that, so when it is time to assemble again you have a little more understanding about setting them to the correct marks.”

Browse our vintage and classic farm machinery on FarmAds HERE.

Out of 8,400 machines manufactured by Merlo in 2022, 7,000 of them were telehandlers, and a significant increase to 7,800 telehandlers is expected this year. Although the home Italian market share remains considerable, 85% of production is exported and the UK is one of the biggest markets taking 10–12% of total production.

Of the machines produced, 50% are destined for agriculture while the remainder are for industrial use and construction.

Ambitious event

The event, at the St Pancras Renaissance Hotel, was attended by 42 of the UK’s 45 Merlo dealers. Merlo handlers were available in the UK for approximately 15 years before Merlo UK Ltd started trading, imported by Selwood.

Merlo president Paolo Merlo and business manager Massimo Biei opened the evening with an address to all the dealers. Paolo stressed that the customer remains Merlo’s focus, and internal manufacturing of 90% of components means that quality is paramount.

Merlo chose a central London hotel for an ambitious event marking 30 years since it founded its Merlo UK Ltd wholly owned subsidiary. There were 42 of the company’s 45 UK dealers in attendance.

Massimo said that part of the secret of making machines that are so easy to use and comfortable is that they are designed in-house using the experienced team’s know-how.

“The agricultural market remains very stable,” he explained. “Often the farm owner is also the buyer of the machine and the main user too, and features such as our effective suspension systems which significantly increase operator comfort have been a real game changer. We want those buying a Merlo to purchase another of the same brand in 10 years’ time.”

Investment in UK

During the past three years, the parent company has invested heavily in the Merlo UK base at Ringwood, Hampshire as well as the sales and product support teams based there. “Our UK general manager, Shaun Groom and his team are all committed to our products and serving our customers. As a private company we are free to invest for the long-term and this will help guarantee success of the brand in the future,” continued Paolo.

Shaun Groom added. “It’s been great to be able to acknowledge in style all those present and that have gone before us during the past 30 years for their success in bringing Merlo UK to where it is today. Whether that be as a customer, dealer, colleague or industry partner, we are truly grateful for the support, and we look forward to the next 30 years. Last year we sold more than 700 units in the UK, which was a great result.”

Pictured (l-r) Merlo president Paulo Merlo, Merlo UK general manager, Shaun Groom and Merlo business manager Massimo Biei with three Merlo handlers displayed in front of the St Pancras Renaissance Hotel for the event.

Dealer awards

Awards were presented to several dealers, two of which had been with Merlo UK since the company’s inception. These were Devon-based CR Willcocks and Wales dealer Brodyr Evans Bros. Brodyr Evans dealer principal, Elgan Evans, said that it had been a privilege to represent the brand for the past 30 years, and he is looking forward to the next 30. Essex-based RC Boreham & Co collected an award for 25 years as a Merlo main dealer.

Looking to future product developments, Massimo and Paolo told Farmers Guide that many farmers across Europe still consider telehandlers to be new products, and that the research and development team works closely with all types of customers and visits them, to ensure the line-up includes the features they need.

Regarding alternative fuels, Merlo already offers its compact e-Worker battery-powered model which was test-driven by this magazine last year. Massimo said that development of medium-sized handlers using battery power is continuing, but that work on future diesel-powered models is also in progress.

Latest features assist future innovation

He added that telematics on existing handlers assist future product development, as engineers can analyse operating data to determine exactly how products are used. “We can identify areas where improvement is needed and make products more efficient.”

Massimo said features such as Merlo’s attachment recognition system, which automatically installs the correct operating profile for each implement, are contributing to extra efficiency. “It allows the operator to work closer to the machine’s limits while ensuring safety,” he explained.

Shaun Groom is pictured with RC Boreham dealer principal Nigel Boreham and director Matt Boreham. The dealer was presented with a long service award marking 25 years representing the Merlo brand.

“It was a fantastic event and everything we had hoped that it would be,” concluded Shaun. “Challenges included getting our three display handlers into central London, but it was very worthwhile and a great way to mark 30 years.”

FG Auctions, part of Fisher German, which has an office in Banbury, sold the 23-acre parcel off the Southam Road in Mollington for £376,035 after attracting 61 separate bids.

The owner of the land, which was previously used as grazing pasture, was unsure about its value after being approached by several people interested in buying it off-market.

He received several offers, which were very mixed and he was not sure if he was getting a good price for the land.

The owner contacted Fisher German’s Banbury office and was put in touch with Tom Dennes, head of online auctions at the firm.

Tom recommended the owner put the land up for auction instead of trying to sell it in the traditional way.

He said: “Putting the asset up for auction is the truest test of its actual value, and you’ll know that the buyer who really wants that asset will be prepared to pay a little more for it.

“This was clearly the case for our client in Mollington, who did not know if the offers he was receiving were actually fair.

“As he also didn’t want to choose one buyer over another for fear of upsetting people, we suggested putting it up for online auction and letting potential buyers bid for it.

“Once the auction began, it was clear that there were plenty of interested cash buyers who were willing to put good offers in to acquire it. After generating a lot of bids, it achieved far more than its £260,000 asking price, which was a brilliant result.”

Online auctions have increased in popularity at Fisher German in recent months due to its convenience and ability to produce a definitive outcome.

And while the traditional method of selling property through private treaty is still very popular, Tom believes online auctions are no longer being considered as a last resort.

“In cases like this where landowners have had parcels of land for a while that later need to be sold, it can often be prudent to consider an auction when the value of the land is difficult to estimate through private treaty,” Tom added.

“Buyers and vendors have told us they love the transparency of the dynamic online auction platform, with all offers visible and the certainty of a sale once the reserve price has been met.

“We would encourage any landowner who is unsure about the value of their land to contact us, and we can advise on the best method to achieve the highest price.”

Köckerling produces a wide range of cultivators, disc harrows and seed drills to suit different soil types and conditions. Its cultivator range has a reputation for long life and low running costs.

Every cultivator in the range has been manufactured to exacting standards using hot drawn box sections as standard; hence the enviable reputation Köckerling now has for long working life, low running cost, and versatile machines, the company explains.

The range of cultivators includes both trailed and mounted versions that are all fitted with the original double STS roller.

The Allrounder Profiline with its four rows of tines spaced at 16.7cm is capable of a number of different tasks, including seedbed preparation after ploughing, opening soil for quicker drying, secondary stubble cultivations, and as a primary cultivator in lighter conditions.

The Allrounder Flatline is equipped with heavy-duty double sprung elephant tines spaced at 130mm over six rows. This machine can work from very shallow or to a depth of 13cm.

The Vario is the flagship of the Köckerling fleet and comes as standard with full hydraulic depth control with 13cm tine spacing over eight rows. The soil and crop residue are carried in the machine for a number of meters to give optimum mix and distribution of crop residue to leave a perfectly level finish in just one pass.

Other cultivators in the range include the Quadro and Vector aimed at deeper working and the Rebell short disc harrow.

Shop used cultivators and tillage equipment at FarmAds.

Opico have launched a new version of its He-Va Combi-Disc at the Cereals Event held earlier this year in June.

The ‘Stealth’ variant of the ever-popular combination cultivator gains ultra-low disturbance legs and a choice of different points depending on the level of sub-surface action required.

Soil-engaging elements for adaptability

Now available in working widths from 2.45–5.25m in both mounted and trailed formats, the Combi-Disc employs two leading rows of soil-loosening legs followed by two rows of serrated Sabre discs to provide a surface chopping and mixing effect. This is all followed up with a V-profile roller to produce a corrugated, weather-proof finish.

It is this combination of soil-engaging elements that makes the Combi-Disc such an adaptable tool. In normal circumstances the tines, discs and press are used in partnership to turn previously uncultivated ground into a seedbed in one pass. When conditions require it, the discs can be lifted completely out of work, enabling the unit to be used as a straightforward subsoil loosener/pan-buster.

Versatility at its best

Likewise, with the legs lifted out of contention, the machine can be put to work as a straightforward shallow disc cultivator.

The addition of new ‘Stealth’ soil-loosening legs add further to the Combi-Disc’s versatility, making it a true low disturbance subsoiler with the added ability of being able to provide some surface tilth creation at the same time.

“With the increased focus on regenerative practices, we’re seeing a need for cultivation kit that can reduce soil disturbance but still deal with compacted layers in the soil profile to ensure decent drainage and rooting to maximise crop potential,” explains Opico’s He-Va product manager, Glenn Bootman.

“With this new leg option for the Combi-Disc, we are answering that requirement. The basic principle is medium-depth, low disturbance soil loosening combined with shallow surface cultivation. I believe that now makes the Combi-Disc one of the most adaptable tillage tools on the market.”

Deep soil loosening with minimal surface disturbance

The 15mm wide Stealth low disturbance leg and low disturbance point are the product of many years of development. Whilst large numbers of growers are now moving towards reduced tillage systems, they appreciate that drainage is key to crop development, allowing timely field operations and preventing the relentless progress of grass weeds such as blackgrass. The Stealth leg and point that He-Va has developed allows deep soil loosening whilst minimising surface disturbance and preventing mixing of the soil profile.The narrower legs are made from ultra-strong Hardox steel and can be interchanged with standard 25mm wide subsoiler legs as necessary. However, it is the point that really makes the difference. The Stealth standard 120mm low disturbance point has a shallower wing angle and shorter nose that has been designed to open up the soil to create drainage fissuring without mixing the whole soil profile.

Those wanting increased soil loosening across a wider profile can opt for a wider 200mm point. Both widths are available with and without long-life tungsten facing.

Shop second-hand cultivators at FarmAds.

As demand for higher capacity combines continues to grow, sales of trailers capable of transporting the wider and heavier headers are also increasing. One company which has seen a big rise in demand is Abrey Agricultural. Farmers Guide‘s David Williams reports.

Based near Saffron Walden in Essex, Abrey Agricultural is the official UK importer for Ziegler products. The German manufacturer offers a range of high-quality header trailers and specialist combine headers – including versions for oilseed rape, sunflower and maize harvesting. The header trailer line-up includes single-axle models suitable for headers up to 7.7m working width and weighing up to 3.6t. Close-coupled, tandem-axle trailers can carry headers up to 9.5m and weighing up to 3.6t, and double-axle trailers with a steering front axle and a fixed rear axle will accommodate headers up to 10.7m and weighing up to 6t.

Exceptional manoeuvrability

While UK sales of all the trailers are increasing, the Abrey team has experienced a significant rise in the numbers of enquiries and sales of its flagship Four Wheel Turn (4WT) trailers. These transport headers up to 12.5m and with weights up to 6t or 7.2t depending on their construction, but the biggest attraction for users is their ability to accurately follow the same line as the tractor wheels when manoeuvring, making it easy to turn into tight field gateways from narrow lanes – typical on many UK farms.

Premium products

Abrey Agricultural managing director, Toby Abrey commented that he feels fortunate to have such a great range of products to offer, and highlighted features which make the 4WT trailers so popular.

These include:

- V-Lock system for easy attachment and securing of the header to the trailer

- Main frame painted to match the combine brand colour – powder coated and oven-baked

- Galvanised supports keep the trailer looking new – for enhanced residual value

- Accurate following and turning into gateways whether behind the combine or a tractor

- Standard tyres 260/75-15, but with options up to 22-ply

- Heavy-duty, 10t-rated axles

- Heavy-duty, twin-beam construction available on 40, 45 and 50ft header trailers

- 40mm/50mm drawbar eye options

- Overrun braking (so trailer always brakes effectively whether behind the combine or a tractor)

- Back-up from the official UK importer – spare parts readily available.

Agco dealer view

Main Agco dealer, Chandlers Agricultural recommends Ziegler headers – especially to customers operating Ideal combines with the widest SuperFlow or Geringhoff headers. “We don’t use any other brand now,” explained Chandlers harvesting dealer principal, Sean Stanfield. “When we assemble the trailers after shipping, everything fits perfectly, and they are incredibly well made.

“Customers love them, and they tow like a train. We use a Ziegler 4WT trailer to transport our demonstration combine headers and, often when we turn up on a farm, the first thing customers comment on is the way the header trailer negotiates turns. Headers lift on and off easily and lining them up is never a problem.”

Sean said that Ziegler has also developed a version of the trailer to transport heavier flex Draper headers. “Since last year, we have been able to supply Geringhoff Flex headers as an approved option for Agco Ideal combines, and our demonstration machine was very busy last harvest. The Geringhoff header, with its ability to flex, requires extra support for transport and it’s heavier, but the specially designed Ziegler trailer makes it as easy to move about as a conventional header.

“The back-up from Ziegler and the Abrey team is always excellent, so the trailers are an obvious choice.”

Essex-based farmer’s experience

Essex-based farmer, James Nott farms near Clare, and he replaced two John Deere combines with 35ft headers, with a single John Deere X9-1100 with a 45ft header, just before the 2021 harvest. He chose a Ziegler trailer.

“I have always got on well with Toby Abrey and the rest of the Abrey Agricultural team,” he said. “I used two different brand header trailers with my previous combines, but the Ziegler 4WT trailer was the obvious choice for the new, wider 45ft header.

“Ziegler’s build quality is very good – better than any other brands I have tried, and the trailer does just what it was bought to do. It turns easily through narrow gateways and the wheels follow the path of the tractor precisely. There have been occasions when I have watched it enter a field and doubted whether it could make the turn, but then it just does – it’s very successful.”

Trailer success led to header purchase

In recent years, James has diversified into growing grain maize. A small area was grown as a trial for the 2021 harvest, more was grown successfully last year and now an even larger area has been planted for the 2023 harvest. A conventional combine equipped with a specialist maize header harvests the grain and, after becoming convinced of the crop’s benefits, James ordered his own 12-row Ziegler header for his John Deere X9 combine from Abrey Agricultural through his local John Deere dealer, Tuckwells.

Several brands were considered before James ordered the Ziegler. “I’ve been very impressed by the build quality and performance of the Ziegler trailer, and I know that the Abrey team will provide excellent back-up, so buying a Ziegler header through Tuckwells, which also supplies and looks after our combines seemed the obvious choice.”

Recommends Ziegler

Tuckwells group sales combine specialist, Steve Bucket said that he always recommends Ziegler trailers to customers. “Toby and the rest of the Abrey team are very easy to deal with and the Ziegler trailer is so good,” he stressed. “We’ve seen a big increase in numbers of four wheel-steer trailers sold recently as this sort of arrangement is essential for moving flex headers over 30ft cutting width on the road.”

View trailers for sale on FarmAds.

Ascenso has become a popular choice since arriving in the UK agricultural scene in early 2021, offering cost-effective, high-performance tyres.

Moving you in the right direction

The farm radial tyres all come with 65k speed ratings and the latest mud breaker technology, which ensures better self-cleaning properties and maximum traction for optimal performance in and out of the field.

The tyre range includes well over 400 sizes for various purposes, including key agricultural fitments such as the 560/60R22.5 floatation tyre, 460/70R24 loader tyre and many more. Ascenso also offers a seven-year warranty on farm radial tyres and five years on bias.

The brand has Original Equipment (OE) status on manufacturers’ products, including Fliegl, Househam Sprayers and Larrington Trailers, with more manufacturers currently testing the tyres.

Tom Bush, director at BA Bush & Son Ltd said: “We have seen a great response to the products, and with the arrival of Ascenso’s range of VF technology in the coming months, we feel the brand will soon cater for all aspects of the agricultural tyre market, making it the go-to brand for farm owners and contractors.”

Ascenso is looking to introduce an additional 300 new sizes in 2023, taking the full product range to nearly 800.

View tractor wheels and tyres for sale on FarmAds.

The below insights from Steve Ellis, managing director at FPE Seals, offer guidance on how farmers can mitigate the machinery crisis amid ongoing cost increases and market challenges.

With inflation of up to 30% in agricultural input costs reversing decades of falling prices, it has certainly been impacting the profit margins of farmers. While attempting to combat these increases, businesses in the agricultural industry need to avoid the cost of replacing expensive and integral equipment.

While farmers gained a boost with the announcement of £31 million being made available by the government for the purchasing of new equipment and machinery, reducing any impact on profit margins is crucial. Choosing whether to repair or replace machinery will benefit different businesses at different times, according to Andrew Powles, managing director at FPE Seals.

“When it comes to machinery, there are steps to take which can keep machinery working. If you understand the age of the machine or the components, how integral it is to the business, and the job it performs, repairing or replacing can both be viable options.

“Replacing frequently worn parts such as seals, hydraulic cylinder parts and gaskets can be a great, cost-effective option to keep a machine running and avoid downtime – particularly when paired with implementations and strategies including predictive maintenance. Naturally, a replacement will sometimes be the sensible option, but only when repair options are unfeasible and machinery is completely at the end of its lifespan.”

Reducing downtime

Downtime in any business, in any industry, can have a knock-on effect across not just the organisation, but also up and down the supply chain. Effective and quality repair work can reduce the amount of downtime within the business, so strategies such as predictive maintenance are employed to avoid this outcome.

Predictive maintenance uses technology, real-time reporting and data in order to monitor parts and components of machinery that may be susceptible to faults and address these before they develop into critical production issues.

Maintaining and repairing machinery throughout the production cycle can have a positive effect on both the output and financial performance of a business. Downtime is reduced – well-maintained machinery will allow production to continue, demands kept up with, and employees utilised for the full duration of shifts.

In times of crisis, when new machinery is ill-afforded, repairing and maintaining to reduce downtime can be crucial. The reduction of downtime in the farming industry is huge – often, jobs are time-sensitive and certain tasks can only take place in small time frames. Repair work can enable these times are kept to, meaning no further impact on profit margins and financial performance.

Employee welfare and safety

Further benefits of repairing agricultural equipment relate to the safety and satisfaction of the workforce responsible for operation. This has positive impacts in more ways than preventing injuries while at work.

The nature of agricultural products means machinery is designed to get jobs done quickly and effectively, and that comes with an element of risk and chance of injury. Of course, safety procedures are in place, but keeping machinery up to the right standard and checking for the need of repairs will enhance the safety of operatives.

Ultimately, safeguarded employees will feel happier within their organisation. There are benefits to this too, which can also be traced back to effective machine repairs. While the reduction in downtime is excellent news for overall business performance, it also helps with company morale. Employees awaiting new machinery to arrive may find themselves with little to do, be utilised in areas of the business outside of their expertise and generally suffer a lack of job satisfaction.

By keeping machinery running with repairs, the business will be able to operate smoothly, with operatives working to their schedules. Production will continue, with workers confident they are using well-maintained, fit-for-purpose machinery, rather than suffering a breakdown and waiting for unspecified periods of time for a replacement.

Cost-effectiveness

Of course, with the rising costs of other farming equipment and necessities, getting the most cost-effective option is imperative. Even with government funding, farmers will still benefit from saving money whenever plausible.

The option to repair rather than replace is often the most cost-effective option. Predictive maintenance can massively reduce or even remove downtime. In cases where a machine needs to be out of service for repairs, the time will be less than waiting for a new machine to be ordered, delivered and installed. Various factors, particularly if shipping overseas, can affect delivery times, making waits unpredictable.

Additionally, there is the cost of training to consider. Mr Powles went on to say:

“New machinery may be evolved from the previous model. Even in these instances, staff may require hours of training to be brought up to speed. Repairing a machine everyone is familiar with, providing it is still capable of high-level performance, means that work and production can commence as soon as the repair is completed.”

Effective repairing can be a great way to combat downtime and cost problems in the agricultural and farming sector. Reducing downtime, improving the safety of staff, and saving money are all benefits that can be attributed to effective repair and maintenance. Coupled with techniques such as real-time monitoring and predictive maintenance, repairs can ensure that new machinery is only required in the rare cases when the machine and components no longer make fixing it viable.