Following the closure of longstanding Scottish auction mart Forfar, Neil Wilson, executive director of the Institute of Auctioneers and Appraisers in Scotland (IAAS), highlighted the critical role auction marts play in the livestock sector and called on officials to think carefully about support for farming businesses.

In a statement, the directors of Lawrie & Symington, the current owners of Forfar Mart, revealed the market was forced to close due to a continued reduction of livestock marketed through Forfar, with cattle numbers this year down 30%.

“Although we have identified other potential revenue streams for Forfar, the market’s main income source must be from livestock sales commission and current throughput numbers, coupled with ever-increasing operating costs, are not sustainable.

“The Directors note the loyalty of their Forfar customers, both sellers and buyers and continue to thank them for their support.”

Responding to the news, Neil Wilson of IAAS pointed out the harsh reality facing auction marts across the UK, which have played a crucial role in the farming economy and are an important part of the social and rural fabric of Scotland.

‘Whilst rising livestock prices have helped offset some of these cost increases, the reality of ever-tightening cattle and sheep numbers means that many marts face pressure trying to grow numbers of animals going through the ring. In turn, putting downward pressure on incomes whilst cost inflation keeps eating away at margins,’ he said.

Mr Wilson explained marts are critical when it comes to the marketing of livestock and machinery, as they offer a ‘collaborative, transparent, price discovery marketing mechanism through the live ring.’ Traditionally, willing sellers and buyers have come together to freely trade and walk away if the price isn’t right.

‘There are very few other sectors who now have the beauty of this system, instead being at the will of major retailers as they are tied into challenging integrated supply chains. See the poultry, egg and pig sectors (and soon to be dairy sector again) for the dangers of this approach,’ he warned.

Marts also ensure livestock can get to market at critical times of the year, which helps promote good animal welfare. Moreover, auction marts support the clear traceability of animals via Scot EiD, something that has been an increasing focus for members of the supply chain following recent revelations.

Last but not least, marts serve as a central meeting point offering farmers the opportunity to network, exchange knowledge and meet members of the local community, which helps offset isolation.

In fact, recent reports published by the Prince’s Countryside Fund and the University of Exeter highlight the critical role marts play in supporting farmer health and encouraging those who are struggling to seek help.

To prevent further colures, Mr Wilson urged all farmers to make use of their closest livestock mart and help promote the viability of local farming supply chains.

‘This closure of a longstanding Scottish auction mart in the Cabinet Secretary’s own constituency should serve as a warning to politicians and officials of the need to think very carefully about support for the farming sector and its supply chain businesses,’ he added.

‘An increased pace in that thinking would also help build confidence across the sector and help ensure a healthy and thriving rural economy – not risk more closures and placing more pressure on farm businesses already facing tough decisions on all areas of their business management,’ Mr Wilson concluded.

Fendt is set to showcase its connected fleet at Cereals 2023 on June 13th and 14th. The event will highlight how Fendt’s machines provide operators with a data-driven advantage, focusing on new technology and models.

Cereals 2023 will mark the first opportunity for arable audiences to see the new 700 Vario Gen 7 tractor, launched earlier this year. The 700 series Vario will be accompanied by models from different horsepower ranges, including the latest Gen 3 500 series and Gen 7 900 series tractors.

Richard Miller, a Fendt representative, said, “This will be an excellent opportunity for customers old and new to see the latest tractors. The Fendt stand will also include the latest Rogator 600 MY23 self-propelled sprayer, the IDEAL combine, and the innovative Cargo T740 with its elevating cab.”

Central to Fendt’s connected fleet is the FendtONE onboard/offboard operating concept. The system, now a familiar feature in Fendt cabs, facilitates data sharing between Fendt machines and farm management systems.

“FendtONE enables data-driven farming, offering operators and farm managers the ability to optimize machinery and operator hours by programming tractors, sprayers, and combines to share data,” Miller added.

Visitors to Cereals 2023 can experience the future of farming firsthand and learn more about Fendt’s commitment to innovation and data-driven solutions.

This year’s Royal Bath & West Show promises to showcase the fascinating history of tractors, featuring over 50 rare and vintage tractors from across the UK. The event highlights how agricultural revolutions have reshaped the British landscape and food production.

Retired chief steward and tractor enthusiast Patrick Palmer, a 40-year Royal Bath & West Show veteran, explains, “Tractor innovations have greatly impacted modern agriculture and society. Mechanization and increased productivity have allowed people to explore other pursuits. The show’s vintage tractor entries provide an up-close look at the evolution of tractor technology.”

A significant development in tractor technology was the transition from tractor vaporizing oil (TVO) to diesel in the late 1940s, improving operations and economic efficiency. Mr. Palmer recounts the issues with TVO, which wouldn’t ignite at low temperatures, necessitating the use of a small high-quality petrol tank to start the tractors before switching to the TVO tank. This process often caused problems, requiring operators to clean the spark plugs and try again.

An early diesel tractor, a David Brown 30d, led the parade at last year’s show celebrating the Queen’s Platinum Jubilee, emphasizing the importance of diesel’s introduction. The event will feature demonstrations of vintage steamers, tractors, and heavy goods vehicles in a dedicated arena and a parade in the main arena on all three days.

This year’s tractor entries include a 1947 David Brown, the oldest entry, as well as other vintage vehicles and implements like a 1948 Grey Ferguson, Fords, a 1986 John Deere 3040 two-wheel-drive, and a 1992 John Deere 4055. The vintage tractor main ring parades will take place on 1-3 June 2023 at The Showground, Shepton Mallet, Somerset BA4 6QN.

Visit the Royal Bath & West Show website for competition entries and ticket information.

In both the Static and Demonstration areas of the Bobcat stand at the Plantworx 2023 Exhibition, the company will be presenting a host of new products for the first time at the show.

The premieres include the first appearance at a UK construction show of both the new TL25.60 telehandler and the T86 R-Series Compact Track Loader as part of the Static display. Other firsts at Plantworx include the new Ground Maintenance Equipment range and an array of products from the company’s Light Compaction line. They continue with the new E19e electric-powered model and the top-of-the-range E88 8 tonne mini-excavator. Bobcat is also presenting for the first time the new MaxControl Remote Control system on a T66 compact track loader in the Demonstration zone.

The New TL25.60 Super Compact Telehandler from Bobcat

As the smallest machine in the Bobcat telehandler range, the new TL25.60 brings the number of rigid frame telehandlers from Bobcat for construction, rental and general handling to 11 models. The new TL25.60 telehandler has been designed for simplicity of use, excellent stability, optimum comfort and safe operation in any type of application.

The TL25.60 is powered by a 75 HP Bobcat Stage V engine. The machine has a rated operating capacity of 2500 kg, offers a maximum lift height of 5.9 m and a maximum reach of 3.3 m. The Bob-Tach carriage (manual or hydraulic) increases versatility by allowing the TL25.60 to utilise attachments designed for the Bobcat loader range.

The T86 – The Most Powerful Compact Track Loader Ever from Bobcat

Delivering a higher engine and hydraulic output, the 5087 kg T86 is the most powerful compact track loader Bobcat has ever built, offering a rated operating capacity of 1780 kg and a tipping load of 3175 kg. Utilising a well-proven Stage V compliant 3.4 l Bobcat engine, producing 78 kW (105 HP) at 2600 RPM, the T86 can be configured for the first time with three different auxiliary functions.

There is a standard flow configuration providing 87 l/min for applications such as load and carry, or where low hydraulic flow attachments are used. Bobcat also offers two additional hydraulic performance functions using the new Electronic Displacement Control (EDC) Pump: a High Flow function giving 138 l/min and a new, industry unique Super Flow function taking auxiliary flow to 159 l/min. Typically, the Super Flow function increases productivity with like-for-like attachments by 15 to 20%.

Commenting on these new product introductions, John Christofides, Regional Sales Director, UK/Ireland, Nordics, Baltics and Eastern Europe for Doosan Bobcat EMEA, said: “Because job sites are becoming ever tighter on space, telehandlers must also become more compact and agile. We have designed the new Bobcat TL25.60 to not only meet this demand but to be the best compact machine on the market. The T86 is also an exceptional machine – the most powerful compact track loader we have ever built, providing even more versatility as both a tool carrier and a workhorse.”

Largest Loader Portfolio in the World

The T86 is part of what is now the largest loader portfolio of any manufacturer in the world. This will be ably demonstrated by Bobcat at Plantworx by the presence of both the L85 compact wheel loader in the Static area and the company’s L28 small articulated loader in the Demo area.

High performance is assured by the combination of the powerful Bobcat engine and the hydraulics in the L85. This is complemented by the high stability, breakout, push and pull forces and a comprehensive selection of Bobcat attachments. The L28 is ideal for a multitude of tasks in a very wide range of industries, offering high lift capacities in confined spaces, ease-of-use with simple intuitive controls and low ground disturbance for working on any terrain.

Ground Maintenance Equipment

Bobcat’s new line-up of innovative Ground Maintenance Equipment (GME) will be on display for the first time at Plantworx. The GME range comprises compact tractors, zero-turn mowers and turf equipment, supplemented by the company’s existing mini track and small articulated loaders. Bobcat is offering three Compact Tractor platforms – the 1000, 2000 and 4000 series – which feature nine new models from 25 to 58 HP designed to meet the varying needs of customers in Europe.

Light Compaction Range

Compaction applications are a required part of numerous industries, and no construction site is complete without a soil and asphalt compactor. To meet this demand, Bobcat is showing the company‘s Light Compaction Product Line for the first time at Plantworx. Altogether, the Bobcat light compaction range comprises seven different product families and offers 37 models, from vibratory rammers weighing 29 kg up to 2.6 tonne tandem rollers.

Clean and Quiet Operations

The E19e being shown by Bobcat at Plantworx is a new 2-tonne mini-excavator to supplement its ever-expanding range of electrically powered machines. The E19e – an electric version of Bobcat’s popular E19 internal-combustion (IC) model – offers zero emissions, low-noise operation and comparable levels of performance to its diesel-powered counterpart. With a width of just 98 cm, the new electric model is easy to operate in even the most confined workspaces, making it ideal for tasks such as demolition as well as outside applications that require quiet, zero-emission operations.

Top-of-the-range E88 Mini-Excavator

The E88 8 tonne Stage V compliant mini-excavator delivers outstanding performance from a compact dimension machine, superb operator comfort and excellent stability with high digging output. The proven Bobcat D24 Stage V 4-cylinder engine offers a maximum power output of 48.5 kW (65 HP) and ensures the highest performance and maximum reliability. To meet Stage V emission levels, the engine uses diesel oxidation catalyst (DOC) and a diesel particulate filter (DPF), replacing selective catalytic reduction, to achieve maximum reliability, efficiency and environmental protection.

Other products in the Static area of the stand include the E10z, E17, E27z and E55z mini-excavators; the T36.120SL and T40.180SLP telehandlers, the T590 compact track loader and the S450 skid-steer loader.

Remote Operation Always at Your Fingertips

Installed on a T66 compact track loader, the MaxControl Remote Control system from Bobcat will be demonstrated for the first time at Plantworx. MaxControl provides a vision of machine control of the future, by enabling operators to control Bobcat compact loaders remotely via an app, using an iPhone or iPad.

With MaxControl, owners of Bobcat loaders do not need the latest machines or costly hardware updates to enjoy remote control. The system is compatible with all Bobcat loaders with Selectable Joystick Controls (SJC) dating as far back as 2004.

Large Choice of Attachments

Some of the latest developments in Bobcat attachments will be on view at Plantworx. They include a new Heavy Duty Box Blade, aimed at both 2D and 3D grading applications. The new attachment offers a Plug & Play integrated solution, that can be installed on Bobcat loaders within a minute.

Suitable for use with most of the models in the Bobcat skid-steer and compact track loader ranges, the new HD Box Blade attachment saves time and money while producing a more accurate and higher precision finish grade, even on tough jobsites. The fingertip controls and user-friendly display on the Bobcat loaders also guarantee ease of operation.

For more information on Bobcat and its products, visit www.bobcat.com

With its model year 2024 tractors, John Deere will take farming to the next level, integrating the new G5 CommandCenterTM displays into all 6, 7, 8 and 9 Series machines, while further enhancing driving comfort.

Ready for the future with the new G5Plus CommandCenterTM

The new G5Plus CommandCenterTM includes documentation, data sync, JDLinkTM connectivity, variable rate application, section control and AutoTracTM guidance as standard on all 6-cylinder 6R, 7, 8 and 9 series tractors. The 12.8-inch G5Plus CommandCenterTM is 33% larger than the previous display, comes with 1080P high definition and a much faster processor. With this update, customers will achieve the highest levels of precision agriculture efficiency and ease of use while ensuring their tractors are ready for the future.

The 6R Series

The model year 2024 John Deere 6R brings with it new developments improving driver comfort. The redesigned steering column and new steering wheel provides the next level in comfort, especially in its on-the-road performance. In addition, the new dampening system available on both Premium and Ultimate seats, the 6R model year 2024 sets new standards.

The 7, 8 and 9 Series

The model year 2024 7R features a new steering system with a 50% increase in steering capacity. This is made possible by larger steering cylinders, which are fitted as standard to all 7R. To enhance operator comfort during transport, the 7R features a new Automotive Type Steering System. It naturally re-centers itself and improves line holding significantly. Known as reactive steering, the feature can be easily activated via a softkey on the CommandCenterTM. Two additional front brake discs enhance the operator’s experience and transport performance. All 7, 8 and 9 tractors have a new highresolution corner post display and a built-in StarFireTM 7000.

Green farming sees a boost as electric tractors emerge as a viable alternative to traditional diesel-powered machines.

The electric vehicle (EV) revolution is making waves in the agricultural sector, with electric tractors emerging as a sustainable alternative to traditional diesel-powered machines. As the world seeks to reduce greenhouse gas emissions and achieve an eco-friendlier future, electric tractors offer an innovative solution for farmers.

By switching to electric tractors, farmers can significantly reduce their farm’s carbon footprint, as these machines produce zero emissions during operation. Traditional diesel tractors, on the other hand, are known to contribute to air pollution and CO2 emissions, which exacerbate climate change.

In addition to being environmentally friendly, electric tractors offer farmers lower operating and maintenance costs. These machines have fewer moving parts compared to their diesel counterparts, which means less maintenance is required, such as changing oil or filters and replacing worn-out belts. Moreover, electricity is generally less expensive than diesel fuel, resulting in considerable savings for farmers.

The performance of electric tractors also sets them apart from conventional options. These machines operate more quietly than diesel tractors, creating a comfortable working environment for farmers and farmworkers. The reduced noise pollution can have positive effects on livestock well-being and the surrounding ecosystem. With instant torque delivery, electric tractors provide superior performance and efficiency, ensuring smooth operation during tasks like ploughing, planting, and harvesting.

Farmers can further enhance their sustainability efforts by integrating electric tractors with renewable energy sources, such as solar panels or wind turbines. Charging electric tractors with renewable energy produced on the farm allows farmers to achieve a zero-emission operation, reducing their reliance on fossil fuels.

Although electric tractors are a relatively new technology, their potential advantages have piqued the interest of the agricultural sector. As more manufacturers enter the market and prices become competitive, the adoption of electric tractors is expected to grow. These machines may soon become a common sight on farms worldwide, as farmers embrace electrification and work towards a sustainable future for agriculture.

Recognizing the challenge of balancing costs, productivity, and sustainable principles in farming, BKT’s latest range of high-tech tires has been designed to meet the specific needs of today’s farmers and reflects the company’s commitment to research and cutting-edge tire solutions.

The negative impacts of conventional tillage on soil structure and function are widely recognized in the agricultural sector, where focus has shifted to minimising the loss of nutrients and organic matter in the soil. As such, conservation tillage practices such as reduced tillage or no-tillage are becoming increasingly popular.

In line with the trend of soil preservation and low-disturbance cultivation, BKT offers numerous tire patterns for latest-generation tractors that enable farmers to transport heavier loads while avoiding soil compaction.

A high-end product suitable for both harvesting and transport operations is BKT’s Agrimax Force, which facilitates effective tillage even on hard soil. Thanks to its IF technology, these tires can carry heavy loads at a lower inflation pressure compared to standard tires, contributing to reduced soil compaction.

The Agrimax Force is well-suited to high-power tractors and combines, offering a comfortable experience, excellent traction, outstanding self-cleaning properties, and low fuel consumption. The range includes the IF 750/75 R 46 version with an impressive diameter of 2.30 metres.

Farmers can also rely on the Agrimax Fortis to deliver enhanced productivity and soil preservation. Featuring a reinforced nylon carcass, the product offers excellent traction and handling, along with the ability to transport heavy loads even at high speeds of up to 40 mph.

Meanwhile, the Agrimax RT 855 provides both superior driving comfort and traction, with its self-cleaning properties allowing a swift transition from field operations to road usage. It also features exceptional flotation properties on the ground that make the product ideal for safeguarding crop productivity.

Another tire incorporating high-end IF technology is the RIB 713, designed to prevent soil compaction by having a larger contact area on the soil combined with lower inflation pressure.

In addition, its steel-belted casing ensures excellent puncture resistance as well as protection against stubbles on the ground. Whereas, its “D” classified speed rating makes the tire a great choice for high-speed journeys of up to 40mph on the road.

Also included in BKT’s extensive range of low-impact tires are Agrimax RT 765, RT 857, and RT 657, all reflecting the company’s commitment to meeting farmers’ needs promptly and efficiently. Renowned for outstanding resistance, these tires provide superb protection against punctures, cuts and stubbles – inevitable risks when working on agricultural land.

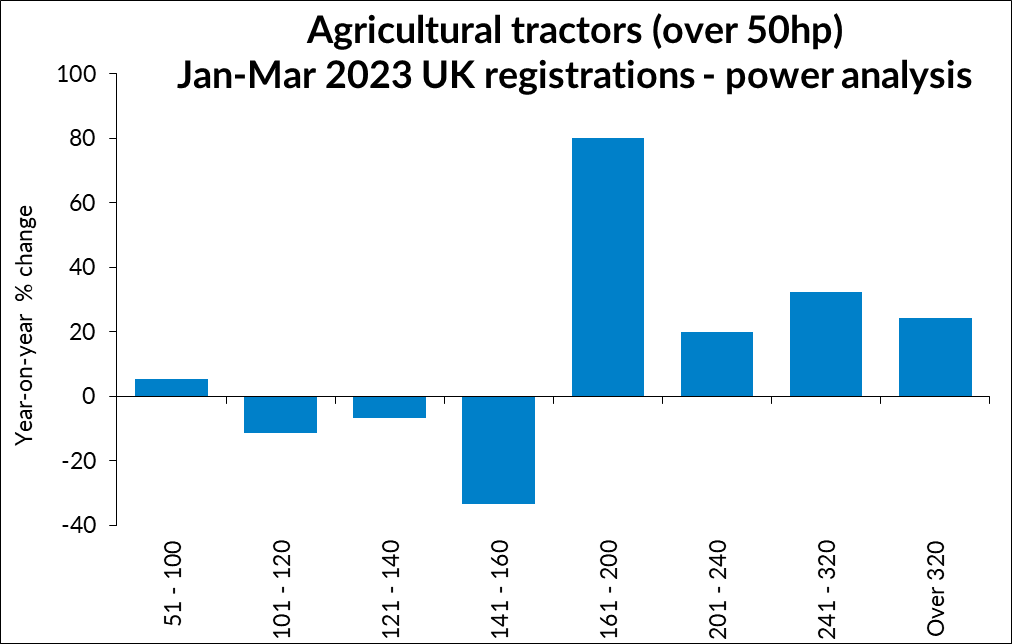

According to the latest report of the Agricultural Engineers Association (AEA), UK agricultural tractor registrations were 10% higher in the first three months of 2023 compared to the same period last year. This is partly due to the increased availability of machines as supply chain disruptions ease.

Most of the growth in registrations from January to March this year was for tractors of 160hp and over, particularly those in the 161-200hp range, where 80% more tractors were recorded than in the same period last year.

Registrations of machines over 200hp have also seen a year-on-year increase of more than 20%, although with fewer sales of tractors under 160hp in the opening three months of 2023.

The trends in higher power bands may partly reflect improved availability as supply chain disruptions subside. The market has also likely seen stronger demand from arable farmers who have benefitted from healthy prices over the last two years.

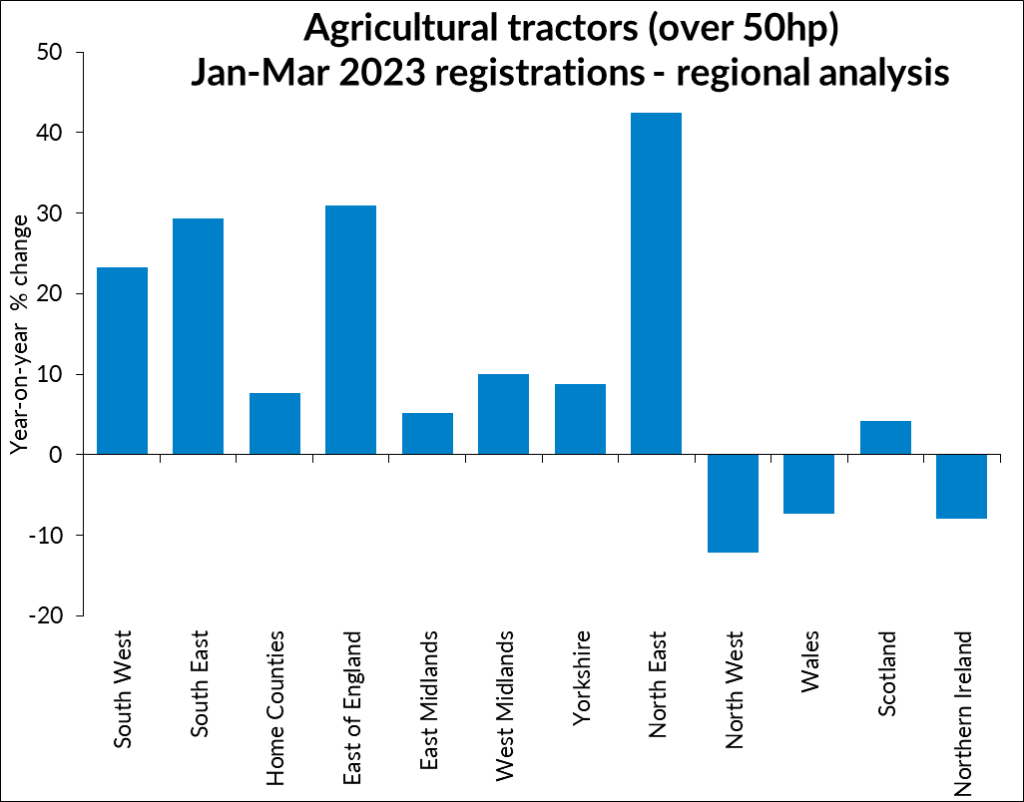

This is also reflected at regional level, as registrations increased across most of England, with the exception of the North West. The biggest increases were in the South of England and East Anglia, both prime arable regions, as well as the North East, although the latter region accounts for only a small proportion of tractor sales.

On the other hand, the figures showed a different trend in parts of the UK dominated by grazing livestock farming, which fared less well financially in 2022. Wales and Northern Ireland have had slightly fewer registrations than last year, with Scotland only reporting a slight increase in numbers throughout the January-March period.

Having seen unprecedented demand for its innovative Claydon Opti-Till agricultural crop establishment machinery, family-owned UK manufacturer Claydon Yield-o-Meter Ltd has expanded its factory in Wickhambrook, West Suffolk, with the new purpose-built building expected to double production capacity and create numerous additional jobs.

The project was supported by a £267,400 Growing Business Fund grant from the New Anglia Local Enterprise Partnership (NALEP) and will help the company meet an exponential increase in orders.

Demand is expected to grow further in 2023 as the business works with its dealer and distributor partners in existing and new markets to develop sales of its Evolution and Hybrid drills, Straw Harrows, TerraStar light cultivators and TerraBlade inter-row hoes.

Company CEO Jeff Claydon commented: “Unlike many other companies in the UK farm machinery sector which import machinery made overseas we design, test and manufacture all our products from scratch, employ local staff and benefit the UK businesses which supply us.”

Mr Claydon, who is himself an arable farmer, founded the company in 1981 to launch the Claydon Yield-o-Meter, the first device to provide an accurate ‘real-time’ reading of crop yields on a display in the cab of a combine harvester.

In 2001, when combinable crop production using traditional establishment methods was no longer economic due to falling grain prices, Mr Claydon developed the Opti-Till Direct Strip Seeding System to reduce costs without adversely impacting output, thereby securing the future of his family’s farm.

Today, the system is helping farmers save the equivalent of up to £250 per hectare on crop establishment costs across a wide range of soil types and conditions.

Opti-Till combines proven stubble management and strip seeding techniques to enable farming businesses to operate much more efficiently, profitably, and sustainably, using just 10 per cent of the fuel required for a traditional plough-based system. This comes in addition to significant yield, soil fertility and environment benefits.

Expanding to meet demand in the face of uncertainties

Global demand for Claydon products has grown ten-for since 2010, and the company is expecting sales to grow exponentially during 2023, despite the undoubted challenges. Like many other UK companies, Claydon must navigate the effects of Brexit, which has made exporting to Europe considerably more difficult, time consuming and expensive.

In 2015, Claydon was awarded the New Anglia Local Enterprise Partnership grant to help the business develop in three stages. The first of these was the construction of new offices adjoining the company’s existing production facility to house additional staff to meet the needs of its growing customer base in the UK and overseas.

Blending in with the existing workshop building and surrounding countryside to minimise their visual impact, the two-storey offices provide 365m2 of accommodation for up to 27 full and part-time staff on the top level.

The ground floor is dedicated to visitors and includes two meeting rooms, a dealer training and presentation studio which can accommodate up to 50 people, as well as commercial-grade catering facilities.

What’s more, a £100,000 investment in solar technologies supplies the building with 100kW/h of electrical energy, reducing reliance on the National Grid at the site and minimising the company’s carbon footprint.

The second stage in the company’s development, which has just been completed, involved the construction of a new assembly building on the footprint of derelict former farm buildings and was sorely needed for the business to grow, Mr Claydon remarked.

“The company is growing rapidly and massively, a highly skilled team is in place, but additional production capacity is needed to manufacture Claydon Opti-Till® products to fulfil demand from markets all over the world, including the UK where sales have doubled.

“Momentum is building strongly, helped by our presence at overseas trade shows, together with the ongoing expansion of our global network of importers, agents, and dealers in 22 countries, whose local knowledge and support gives potential customers confidence to invest in UK-manufactured products,” he added.

The decision to proceed with the development marked the company’s 40th anniversary in July 2021. The footings were completed by Claydon staff in winter 2021 and construction began the following summer. Although the project was managed in-house, due to delays in obtaining contractors and materials as a result of Brexit and Covid-19, progress was slower than anticipated, Mr Claydon noted.

Having gone through major expansion, the company’s focus now is to recruit additional staff to fill the range of vacancies available at its Wickhambrook factory.

With the requirement for staff in the assembly and yard area alone set to triple in 2023, the company is looking to fill rewarding opportunities across all sectors of its business, from design, procurement and sales positions to welding, painting, fabrication, and assembly roles.

Oliver Claydon, the company’s commercial director, said: “This significant investment we have made in these new production facilities will help us to take a quantum leap forward to meet demand for Claydon products and is a key part of our long-term plan to develop the potential which exists all over the world.”

A Claydon Evolution M6 drill operating on the Claydon farm.

Blickfeld’s LiDAR sensor technology is being applied for research in various use cases with the goal of evaluating autonomous functions for enhanced efficiency in agricultural machinery and equipment

Munich, October 5, 2022: Blickfeld, a Munich-based manufacturer of holistic LiDAR sensor solutions, and AGCO, a leading global developer and manufacturer of agricultural machinery, have together utilized Blickfeld 3D LiDAR sensors for research for automation of tractors and harvesting machines. By using Blickfeld’s LiDAR technology in smart digitization solutions, autonomous harvesting functions are expected to be promoted, driving sustainability and operational efficiency in agriculture.

3D LiDAR captures the environment three-dimensionally

Until now, a higher degree of automation in agriculture has been hindered by the limited technical possibilities for precisely determining the environment. Unlike cameras, the 3D LiDAR sensors reliably capture the environment in three dimensions, even in very difficult environments and operating conditions. LiDAR technology opens up endless potential applications that will help the world of agriculture become even more efficient.

Kenneth Düring Jensen, Manager, Research & Advanced Engineering, Gold Harvesting: “The precise perception of the environment is an important basis for identifying the most efficient measures to support smart and sustainable agriculture, and executing these measures optimally, in real-time. We are very pleased to explore the possibilities with Blickfeld’s LiDAR sensors for our research projects. The technology, thanks to its performance, efficiency, robustness, and flexibility, could support us in enabling improvements in key agricultural areas.”

Dr. Florian Petit, the co-founder of Blickfeld, said, “We are very pleased that AGCO, one of the leading experts in agricultural machinery, is exploring our Blickfeld LiDAR solutions. We want to make the world a more efficient and livable place through breakthrough digital solutions – and smart, resource-efficient agriculture is an important part of that journey. We are convinced that our unique LiDAR solutions will make a real difference.”