Large-scale sheep thefts are on the rise, according to new figures from NFU Mutual, which has released top tips to help farmers deter livestock thieves.

The latest figures suggest farm animals worth £3 million were stolen from UK farms last year. Sheep thefts over the past two years have contributed to a 19.4 per cent rise in value, making rustling one of the costliest crimes for the farming sector, after agricultural vehicle and machinery theft.

Rural affairs specialist Rebecca Davidson said: “Rustling has always been an aspect of farming but ten years ago we would rarely see claims of more than a dozen sheep taken in one go. We are now regularly getting reports of fifty to a hundred sheep being taken in a single raid and it is devastating for farmers as they deal with the aftermath.

“As well as causing untold suffering to sheep, which may be in lamb when they are stolen, rustling is causing high levels of anxiety for farmers who have built up their flocks over many years.”

She added that rustlers are becoming more skilled and organised, quickly loading sheep onto trailers and lorries at night, and gangs are now using working sheepdogs, which have also been stolen.

The company says there are three distinct types of livestock theft currently taking place – large scale theft of livestock destined for the food chain; pedigree rams stolen for their value as breeding stock; and money laundering by gangs who buy and sell sheep at auctions to launder money.

One of the most alarming trends NFU Mutual has seen develop in recent years is the illegal butchery of animals in the field, which is deeply disturbing for farmers and their families, as well as being financially damaging.

“We believe that meat from stolen animals is being sold on the black market and undermining welfare standards,” Rebecca said. “Meat which has been butchered in unhygienic conditions, and may be from animals which have had medical treatment, poses a real threat to human health.”

The public are being advised to look out for the Red Tractor logo and not buy meat from unusual sources.

NFU Mutual’s top tips for deterring thieves are:

- Ensure stock is clearly marked and records are up to date

- When possible graze livestock in fields away from roads

- Check stock regularly – and vary times of feeding/check ups

- Consider a high-tech marking system such as TecTracer, which puts thousands of coded microdot markers into a sheep’s fleece

- Join a Farm or Rural Watch scheme to share information about rural crime in your area

- Ask neighbours to report any suspicious sightings to the police, or to give information 100 per cent anonymously to the Rural Crime Hotline 0800 783 0137, www.ruralcrimehotline.co.uk

- Dial 999 immediately if an incident is taking place – do not approach criminals.

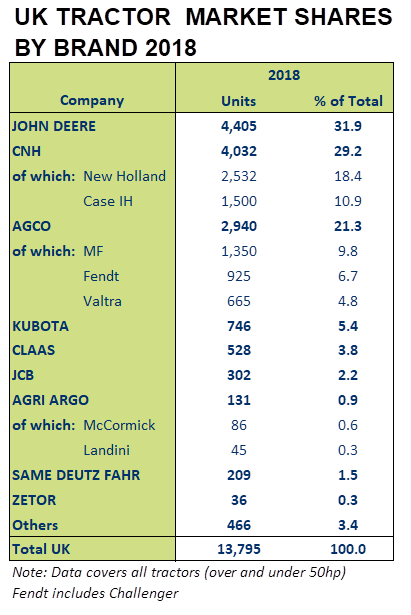

The total number of tractors registered in 2018 was 13,795, including both agricultural tractors (over 50hp) and compact tractors (50hp and below). The table below shows the number of machines and market share recorded during that year by brand. As always, data are released after a one year delay due to competition law restrictions; figures for 2019 are due to be published in early 2021.

Agricultural machinery specialist SlurryKat was given a Royal nod with a visit from Princess Anne.

Based in Waringstown, the company welcomed Her Royal Highness, the Princess Royal on Thursday 16th January. The Co. Armagh firm is at the forefront of innovative slurry handling solutions for Agricultural and Bio-Gas industries.

The Princess was led on a tour of the production facility by CEO Mr Garth Cairns and was given a briefing about the components used for building tankers as well as 3D CAD models of the equipment. She viewed laser cutting machinery and the welding process before being briefed about the construction of umbilical systems, components and attachments.

The tour concluded in SlurryKat’s new state of the art painting and final assembly facility, where the Princess observed the painting process and final assembly of the products.

Princess Anne was invited to unveil a plaque to commemorate her visit and was presented with flowers and a miniature model of a SlurryKat tanker by Joshua, (4) and Sofia (2) Cairns.

Mr Cairns commented: “It was an honour to host the HRH The Princess Royal at SlurryKat and share my journey of the past 13 years of the company with her. It was fantastic to be able to showcase some of the engineering expertise that Northern Ireland has to offer.”

AGCO, a global leader in the design, manufacture and distribution of agricultural machinery and solutions, confirms further expansion of its Beauvais site. This announcement has been made public by Martin Richenhagen, Chairman, President and Chief Executive Officer of AGCO at the Choose France summit, led by French President Emmanuel Macron.

“We are delighted to keep our promise, made exactly one year ago at the Beauvais 3 Logistic Centre opening event, to announce the acquisition of the 15.7ha of the next door ex-Froneri Site, effective from 19th September 2019 to consolidate our presence in Beauvais,” said Martin Richenhagen, Chairman, President and Chief Executive Officer of AGCO Corporation.

“With this new acquisition, we are now looking at investing an additional €40 million as we develop a cutting-edge industry 4.0 site. This will add 200 new sustainable jobs to the already 100-plus jobs created with Beauvais 3, back in September 2018. At the end of this new investment programme, AGCO will have created 300 new jobs for its local Beauvais community as we intend Beauvais to become the Global Home of the Massey Ferguson Brand.”

The acquisition of the 15.7ha ex-Froneri site, which includes 4.5ha of buildings, signals AGCO’s strong appetite for continued investment, which will enable Massey Ferguson to meet growing demand for its straightforward and dependable equipment.

The expansion will support the integration of new activities through vertical integration, including:

- Tractor customisation workshop to offer a wider choice to our customers, fitting specific, customised equipment and accessories off the production line to meet any single customer’s needs.

- Additive manufacturing facility, benefiting from acquired expertise on prototype parts 3D printing for manufacturing for small series, complex and customised parts production to support the tractor customisation workshop. This activity will start in February 2020 for plastic parts and, for metal parts, during 2021.

- In-house production of hydraulics pipes, which are currently outsourced from suppliers in Europe and Asia. Our objective is to produce these hoses in Beauvais, integrating advanced technologies for production, quality control and storage – this activity will start in April 2020.

- Gearbox remanufacturing, offering customers a cost-effective alternative to a brand new replacement. Remanufactured gearboxes will leave our factory as good as new and rebuilt to the same specification as the OEM (Original Equipment Manufacturer) standard.

This extra space will also allow AGCO to roll out a range of new agricultural machinery, which is a key part of the company’s growth plans for Massey Ferguson. With 18 new tractor ranges launched since 2015, and a further 10 to come by 2023, Massey Ferguson is meeting the diverse requirements of farmers who are looking to invest in straightforward and dependable equipment. This project will allow AGCO to accelerate innovation by:

- Capitalising on the local business environment, keeping suppliers close-by will facilitate a more efficient ‘just in time’ approach to production, which will help drive value across the manufacturing process.

- Optimising available resources for new product design and testing, accelerating time to market through an improved R&D centre.

- Redefining the Beauvais complex as an expanded centre of excellence for Massey Ferguson’s tractor engineering and manufacturing by providing the necessary space to improve quality, accelerate R&D and roll out innovation from a single site.

- Driving greater value through a more efficient site structure that enables the company to relocate its Engineering and Purchasing activities, currently in congested sites inside and outside our existing Beauvais complex.

“Massey Ferguson has been a world dominating tractor brand for more than 60 years – for as long as we have been manufacturing in Beauvais, France,” comments Martin Richenhagen.

“The national and local community and authorities in Beauvais, Agglo du Beauvaisis, Oise, Hauts-de-France and the Préfet Cabinet of Oise, representing locally the French government, have been a consistent source of support for AGCO and our status as the largest private employer in the Picardie region.

“This is no coincidence. They have created a business-friendly environment that makes it possible for large international companies such as AGCO to invest in France.”

“This new, single unified site presents opportunities for AGCO and Massey Ferguson to implement growth plans, previously limited by a lack of space,” adds Martin Richenhagen

“After refurbishment, the newly created and unified Massey Ferguson Centre of Excellence for Engineering and Manufacturing will cover a total area of 54ha and employ up to 2,500 people, including in its GIMA and AGCO Finance joint ventures.”

“This project will create the conditions for the revitalisation of the area’s economic activity by creating new jobs. More than €250 million has been invested in Beauvais in the past eight years. Our growth strategy is gaining momentum and the proximity and availability of a skilled workforce makes this new investment programme even more compelling.”, concludes Martin Richenhagen

The single, unified Beauvais campus will encompass the full design, build, testing and manufacture of new models and it is the Company’s intention to ramp up the site’s production volumes to 18,000 tractors/year to meet market demand.

Environment secretary Theresa Villiers has said the new Agriculture Bill, introduced today, will “transform British farming”, rewarding farmers in England with public money for public goods.

The bill, first introduced to parliament in 2018, will replace the current subsidy system of Direct Payments, which pays farmers for the total amount of land farmed.

Direct Payments will be phased out over a gradual transition period, starting in 2021 and continuing for seven years.

Instead, the new system will reward farmers and land managers for providing public goods such as better air and water quality, higher animal welfare standards, improved access to the countryside or measures to reduce flooding.

Theresa Villiers commented: “This is one of the most important environmental reforms for many years, rewarding farmers for the work they do to safeguard our environment and helping us meet crucial goals on climate change and protecting nature and biodiversity.

“We will move away from the EU’s bureaucratic Common Agricultural Policy and towards a fairer system which rewards our hard-working farmers for delivering public goods, celebrating their world-leading environmental work and innovative, modern approach to food production.”

NFU president Minette Batters described the bill as “one of the most significant pieces of legislation for farmers in England for over 70 years”, adding that she was pleased the government had listened to many of the NFU’s concerns.

However, she added that farmers would still want to see legislation providing assurances that future trade deals will not allow imports of food produced to standards that would be illegal in the UK.

She added that it is “encouraging” to see that the bill now recognises the link between food production and caring for the environment. Commitment to a long-term future budget and the government’s pledge to improve transparency and fairness in the supply chain were also cited as being particularly important parts of the bill.

The bill legally requires UK Government to report regularly to parliament on food security – a move which was welcomed by the NFU, though Minette Batters said it must not become a “box-ticking exercise”.

Later in the transition period, the government has plans to ‘delink’ Direct Payments from the requirement to farm the land, giving farmers greater flexibility to plan for the future. These payments will be able to be used for investing in business, diversifying, or helping new people enter the sector.

The government has said funding available for 2020 Direct Payments will be the same as in 2019. In future years the government says it is committed to matching the current budget available for farmers in every year of this parliament.

NFU said it will scrutinise the bill over the coming days to ensure it provides the policies needed for a thriving farm sector post-Brexit.

At a new product exhibition held in Kyoto City, Japan on 15-16th January 2020, tractor and heavy equipment manufacturer Kubota Corporation demonstrated their concept machine, ‘X-Tractor’. Equipped with artificial intelligence (AI) and electrification technology, this “dream tractor” concept is a completely autonomous tractor that represents Kubota’s view of our farming future.

The ‘X-Tractor’ has been initially developed to address the challenges facing Japan’s farming industry, including an ageing population that manages growing farm operations with labour shortages and low operating efficiency. As smart farming becomes an urgent necessity for Japanese farming, Kubota are incorporating environmental efforts into the new futuristic design, where the machine’s lithium-ion and solar batteries contribute zero emissions.

With the aid of AI, weather data and growth rates can be analysed by the tractor to farm as efficiently as possible, and as a totally autonomous operation. This information can also be shared to other ‘X-Tractors’ working on a farm, to create a synchronised fleet of agricultural machines.

The four-wheeled crawler achieves stable autonomous driving even on wet and uneven terrain and can change its shape to maintain height at an optimal level during various processes. For example, tasks that require high traction, the contact area with the ground can be increased by lowering the tractor and therefore its centre of gravity. The in-wheel motor makes it possible to arbitrarily change the rotation speed of the four crawlers to achieve a small turning radius for autonomous operation on various types of land.

Kubota’s ‘X-Tractor’ has exhibited half a century after exhibiting its first ever concept tractor at the Japan World Exposition held in Osaka in 1970.

British dairy needs the right investment and trade agreement to grow and deliver quality products, the NFU has said at the first big dairy conference of the year.

Speaking at the Semex Conference in Glasgow, NFU vice president Stuart Roberts said 2020 offers more optimism than last year, which was dominated by uncertainty for the sector, particularly in the liquid milk market. It has seen huge implications for dairy farmers, including those affected by the Tomlinson’s closure.

However, he said the government must back British farming like never before, putting in place policies to ensure dairy businesses can prosper.

“It’s absolutely clear that whether it’s milk, cheese, butter or yogurt, the British public still love and value dairy with 98 per cent of households regularly buying dairy products that are nutritious and produced safely to high standards of animal welfare and environmental protection,” he commented.

Ensuring a free and frictionless trade deal with the EU must be top of the list, he added, as well as a future trade policy that doesn’t allow imports of dairy products that would be illegal to produce here.

“The alternative is the damaging threat of trading on World Trade Organisation (WTO) rules meaning UK dairy farmers would face higher fees on exports, as much as 48 per cent on butter and 57 per cent on cheddar cheese.

“With the UK dairy sector exporting 3.2 billion litres of products to the EU, it’s essential we secure a deal with the EU or face costs in the region of £500m.”

The much anticipated new cereal fungicide, Revystar XE, has received authorisation in the UK for use on all cereal crops.

Revystar XE contains the isopropanol-azole, Revysol (common name mefentrifluconazole), the first of its class to be introduced to the market and Xemium, BASF’s best-in-class SDHI (succinate dehydrogenase inhibitor).

Neil Kay, BASF’s Business Director of Agricultural Solutions for the UK and Ireland says:“This is very positive news for the farming sector. This authorisation comes at a critical time into what is widely regarded as an increasingly challenging regulatory and disease control environment.

“This active ingredient is an important, robust mode of action for the market and we are so pleased to be bringing new chemistry to market that will practically and financially help growers,” Mr Kay notes.

BASF’s Ben Freer adds: “I’m sensing the industry’s sigh of relief that this new chemistry is here. With the loss of chlorothalonil (CTL) and the decline in efficacy of the conventional triazoles, prothioconazole and epoxiconazole, the timing for this authorisation is pivotal.

He adds that from the outset BASF took a completely fresh approach to developing the Revysol molecule,with regulatory needs driving the product development process.

“Key to the success of this authorisation was our decision to establish a new screening system to optimise the efficacy of Revysol against fungal pathogens whilst, in parallel, creating a product with a favourable regulatory profile. This has taken a big shift in mindset as well as in the process.”

Mr Freer also says that Revystar XE has been formulated for fast uptake giving farmers greater confidence following deteriorating weather after application.

“Revystar XE can minimise weather-related risks in comparison to conventional azole-based products,” he says. “It is quickly rainfast, has UV stability and is effective at a range of temperatures.”

He explains that typically, cold temperatures during application are known to limit the uptake of conventional azoles and compromise their performance, however, Revystar XE’s proven fast uptake, means that it performs well, even in cool conditions.”

He adds that Revystar XE’s rapid foliar uptake makes it quickly rainfast, ensuring excellent knockdown as well as long-lasting protection.

“The weather-related benefits extend into the warmer weather too,” he says. “In the summer months, high UV radiation can accelerate the degradation of conventional azoles and shorten the period for which the fungicide has an effect.

The rapid foliar uptake of Revystar XE gets the fungicide into the plant, where it is no-longer at risk of UV breakdown, even when radiation levels are high,” Ben concludes.

Case study:

A group of 50 farmers, who are part of BASF’s Real Results Circle, have been undertaking field-scale trials of Revystar XE on their farms.

One of the farmers, Richard Budd, who farms at Stevens Farm in Kent, has half of his planned area of wheat drilled this season. He says: “Our Revystar treated crop yielded 0.99t/ha more than our farm standard, and was greener for 10 days longer, which kept the yield up. We just don’t expect to yield gains like this nowadays, which is why we need intelligent chemicals like these.”

Mr Budd “It certainly held its own and its kept the crop clean. It’s given me the confidence that in a challenging year we will get good performance out of it. I’ll certainly be using Revystar XE in the Spring.”

James Chapman MBE drew a crowd to the farm safety zone at Lamma this week, where he spoke candidly about the loss of his left arm in a serious machinery accident, and how it inspired him to try and help other farmers.

It was a cold Friday in 2005 when James went to help at a friend’s farm near Rugby. Having grown up on the family farm in Warwickshire and later set up his own contracting business, there was never any doubt that farming was the job for him.

On the day of his accident, he had faced a number of delays due to machinery problems and was under pressure to get the job done and make up for lost time. While he was checking some equipment that appeared to be malfunctioning, part of his clothing got caught in the PTO shaft and he was flung over the top of the tractor, tearing off his left arm.

Following the accident, James’s three-year relationship ended and his contracting business tailed off. Speaking to the crowd at Lamma about the impact on his mental health, he said he considered ending his life but joked that laziness kept him on the sofa and his friends helped drag him back to the pub and normal life.

The accident prompted him to try and improve safety in the industry and prevent other farmers suffering injuries or fatalities. He was awarded an MBE for services to farm safety in 2012.

A Nuffield scholarship took him to the US, Canada, Australia and New Zealand to find out more about global farm safety, but he says there is no one country that is doing better than the UK. As a result of his work, he believes the answer is not more legislation, but a change in culture.

Farmers often relish, but also normalise the risks associated with the job, he said.

“We are proud of our near misses and even boast about them. We risk our lives every day to provide food and we need to stop glorifying the risks and the dangers, praising those farmers who do a good job when it comes to farm safety.”

Farming comes with multiple pressures – not least time, finance and weather – which can result in corners being cut. While farmers possess multiple skills and carry out very varied tasks on-farm – rather than getting in specialist help – formal health and safety training often does not form part of the picture.

Figures from the Health and Safety Executive show 39 people were killed as a result of farming and agriculture-related activities in 2018/19. Out of the main industrial sectors, agriculture has the highest rate of fatal injuries among workers and the rate of fatalities is 18 times higher than the average across all industries.

James says: “Safety isn’t about paperwork or legislation; it’s about going out and doing the job you love doing and being able to come home safe afterwards.”

However, James noted the large number of farmers present at his talk and said it is a sign of the times changing, as safety discussions would not have drawn a crowd 10 years ago.

Image © Farm Safety Foundation

Chancellor Sajid Javid has confirmed just under £3 billion of funding for farmers and rural communities in 2020, to provide support after Brexit.

The UK is set to leave the Common Agricultural Policy (CAP) Direct Payments Scheme, which supports farmers across Europe with subsidies, in 2020. It will be replaced with a new system based on public money for public goods.

This cash boost from the government will allow funding for Direct Payments in 2020 to continue at the same rate as in 2019, supplementing the remaining EU funding that farmers will receive for development projects until 2023 at the latest.

It will be available from late 2020, as in previous years and totals £2.852 billion, topping up the remaining EU funding and matching the total funding for Direct Payment available for 2019.

Funding will be spread across two financial years.

Environment secretary Theresa Villiers, said: “Outside the EU we will have a simpler, fairer funding system – one that rewards farmers for enhancing our environment and safeguarding our high animal welfare standards.

“We are committed to making sure our rural communities feel the benefits of Brexit and will ensure our farmers get a better deal.”

Announcing the news, HM Treasury said it will guarantee the current annual budget to farmers in every year of the parliament.

A further £206.6 million has been awarded since Spending Round to support the farming sector in Scotland and Wales.