The Trans-Cap, Joskin’s all-purpose tipping trailer, has multiple benefits that make it a firm favourite – starting with its V-shaped open drawbar, attached on both sides of the chassis to increase stability, and with cross-springs for a smoother suspension. The narrow chassis allows for wider tires, reducing soil compaction.

Combined with Joskin’s roll-over bogie, a running gear using spring leaves connected to both axles on a central pivot point, this makes the trailer more comfortable to drive and easier to pull in tough conditions, thanks to its 240mm clearance and constant weight repartition, Joskin continues.

The narrow chassis houses a single tipping ram in a double-oscillating frame, ensuring maximum stability and smoother tipping.

The monocoque tapered body uses a single sheet of special high tensile steel for each side and for the floor, and is robot-welded to increase the quality and lifespan of the trailer.

Wider by 8cm at the rear, and combined with the high clearance hydraulic door, the transported material is unloaded quickly and without any constraints. All rams are equipped with check valves for added safety.

Trans-Caps Advantage series are in stock and at discounted prices.

Visit the Joskin website for more information

View FarmAds trailers for sale

Slurry from housed livestock contains valuable nutrients, phosphate and potash as well as a host of other things that should be recycled back to land in an environmentally sustainable manner.

Waste is created from cow manure and water and provides a fantastic, natural fertiliser that farmers can use to encourage the growth of grass and other crops. It can, however, create significant pollution to our water and air. Every livestock farm has to deal with waste and with the increasing focus on environmental impact, it’s key that it’s managed appropriately.

Enter the Harry West Dual spreader range of machines, designed as a steel container that holds farm manure and slurry securely while travelling to the spread site.

A steel door allows metered discharge when operated hydraulically left to right across the rear of the Dual Spreader’s output rotor.

The rotation of the output rotor forces the manure, under slung, against the machine’s sprung plate allowing the breakup of the material and gives a low trajectory across the field. This limits the muck from being caught airborne and gives a more even and controlled spread.

This operation provides a positive spread of up to 21m, giving excellent coverage on both grass and arable land.

Material is eased down internally onto the feed auger with a standard agitator plate (walking wall) along the full length of the steep sided spreader.

The feed auger pulls the material forward towards the rear of the tractor giving a safer operation and certainty when used on undulating and boggy land.

James Llewellyn, sales director said: “The Harry West Dual spreader has evolved over a number of years into the all-round spreader, working with all types of material in a safe and environmentally sustainable method.”

Please contact your nearest West dealer for further details.

View FarmAds muck and slurry equipment for sale

History of drapers

Turning the clocks back, even the earliest binders and harvesting machines used draper style feeding in the form of canvases for the benefits of heads-first feeding to the threshing unit. The practicality and maintenance of damp canvases though was one of the main causes of the shift towards auger headers. For smaller headers, the simple driveline and rigid frame provided a low-cost and functional approach to combine feeding.

Fast forward to 1986 with many technological advances in draper manufacturing and engineering, MacDon’s experience with swather draper headers generated demand to fit its rubber-belted swather header to combines. The cost and performance benefits of heads-first feeding were again realised and from there exploded the demand for combine draper headers in the American Midwest.

Multi-crop advantages

In a period of wet weather, drilling windows and harvest windows are shortened; both of which put pressure on the combine when it is most critically needed. Crop diversification is one solution to this challenge so long as the crop can be suitably harvested when ready.

The MacDon FD2 has been tested in practically every crop around the world, in pretty much every condition anyone would dare to put in front of it. In many scenarios, the combine header is known to be the limiting factor for combine throughput where lodged wheat or damp, dewy barley make for a very unpleasant harvesting experience. Having the draper feeding and the floating headstock make this significantly easier on the operator, giving the farm the confidence to plant a range of diverse crops and trusting that the header will not be the limiting factor at harvest time.

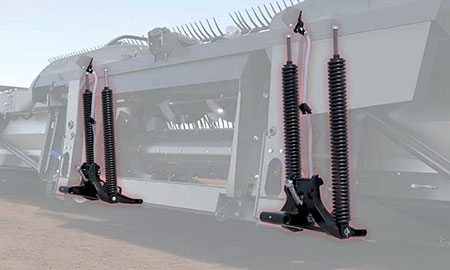

Floating linkage

The wet weather doesn’t just create pressure at drilling and harvest time though. The need to get fertiliser on early is notorious for leaving rutted tramlines which cause havoc with height-sensing combine headers at harvest. Having the header mounted on a floating linkage takes the stress out of navigating these, which MacDon says it has perfected since the release of the FlexDraper in 2004. The system works neatly in conjunction with the combine’s existing auto header height control system, but allows the combine to take a relaxed back-seat approach to ground following. The instant mechanical response means badger sets and tramline ruts are no longer a worry to the operator, and negate the downtime associated with changing knife sections.

Along with the floating linkage, the frame of the FlexDraper is split into three sections. Each of these follow the ground independently, allowing the header to work much closer to the ground where laid crop or short crops are nestled in valley bottoms or over ridges in the field. While this capability was developed with the terraced fields of the Midwest in mind, it has just as equally found a new home in the rolling vales and hills of the UK. Being able to cut all the crop without the need to cut at multiple angles means reduced field passes and an easier operator experience.

Integration

Just as the three-point linkage and Isobus has standardised the tractor implement side of the industry, MacDon says it is leading the way with ensuring seamless compatibility between combines and combine headers. By interfacing through the existing combine’s controls, the MacDon FD2 retains the functionality and features that one could expect from a combine manufacturer’s own header.

Knowing that the header can be adapted to a range of combine brands allows farmers to invest knowing that the header can be kept for multiple combines, regardless of whether the combine colour changes down the line. Not many will look back to the days when a plough and tractor were bought as a combined unit; the practicalities and benefits associated with the commonised three-point linkage really set the bar for justifying capital expenditure, allowing tractor and implement manufacturers to innovate and specialise separately in their particular area.

In an uncertain economic climate, there is a tendency to hold on to equipment longer and make purchases that have a more direct impact on business performance. While the FD2 will improve the productivity of the combine, the additional investment needs to be justified, the manufacturer acknowledges. The high serviceability and minimal regular maintenance of MacDon headers lends itself to a long service life, evidenced by many FlexDraper headers having done several thousands of hours. This longevity helps maintain the resale value and further reduces the cost of ownership. Retaining the header for multiple combines is a new concept to the European market but one that is firmly established in other markets, allowing equipment to earn its full potential rather than being traded prematurely.

The trend towards draper headers has been accelerated by the growth of farm businesses and the need to get more out of the combine at harvest. The MacDon FlexDraper has led the European charge in the shift to draper headers and continues to deliver on innovation and performance to ensure it can meet the demands of modern agriculture in challenging conditions.

Visit the MacDon website for more information

View FarmAds combine harvesters for sale

You may think that there is only a slight difference in the width of row crop tyres, but depending on the size of your farm, the difference tyre width makes to potential crop yield is noticeable.

Spraying, for instance, at this time of the year requires numerous trips across your fields and the impact in terms of soil damage and crop damage with traditional wide tyres can really affect your bottom line.

Unlike wide tyres which crush the crops, narrow row crop tyres have less impact on the soil and allow young seedlings to develop correctly throughout the field. In addition to being easier to drive between the rows of crops with narrow tyres compared to wide tyres, the limited width of the footprint in the soil with narrow tyres reduces the number of plants damaged as well as the impact on your crop’s root system.

Ascenso’s narrow row crop tyres

Ascenso’s VDR 900 VF radial tyres are engineered to carry 40% more load than a conventional radial tire, or the same load at 40% lower pressure.

These tyres have been designed with stronger lugs, a large contact patch that gives excellent traction and with the unique and innovative design of Ascenso’s mud breaker technology, the self-cleaning characteristic of the tyre decreases slippage, delivers lower fuel consumption, and increases overall productivity.

With a set of high-tech narrow VF tyres, you can work with lower inflation pressures, use a high-capacity spray tank, wide booms, and see a significant improvement in crop yield, the company concludes.

A fixed cattle handling system is a permanent infrastructure used to manage and handle cattle in an efficient and effective manner. Many farmers will have at some point considered investing in a fixed cattle handling system to improve their operations and optimise their resources, but the planning and cost can be somewhat off putting. However, with the most recent round of the FETF grant funding, you could install a standard or bespoke fixed cattle handling system that will help manage your enterprise at a significantly reduced cost, IAE says.

Why make the investment?

Increased productivity: One of the main benefits of a fixed cattle handling system is the potential for increased productivity. With a well-designed system in place, you can streamline the handling process, reducing stress on both the cattle and the handlers. This will lead to improved cattle flow, faster sorting, and reduced time spent on various tasks such as weighing, TB testing and applying pour on treatments, ultimately resulting in higher efficiency and productivity.

A key design feature for improving the flow of cattle, IAE says, is to incorporate its 6.2m diameter forcing pen, which turns the cattle through 180 degrees so that as they move down the race, they are heading in the direction of where they came from; be that a field or housed environment. Naturally, cattle will always want to travel towards where they came from and therefore making that 180-degree part way through the handling system is a simple way to generate a consistent flow of animals.

Improved animal welfare: Investing in a fixed cattle handling system can greatly enhance the wellbeing of the animals. The system allows for better control and handling, minimising stress and potential injuries during loading, unloading, weighing, and veterinary procedures. By providing a safe and low-stress environment, you can ensure your cattle’s health and welfare, leading to healthier animals and improved overall herd performance.

To enter the handling system, cattle must flow through two seven-rail 4,880mm x 3,195mm holding pens, that are purposely designed to hold only a small number of animals at any one time. This is because cattle in small numbers remain calmer and move better, greatly helping to mitigate any stress the animals may feel.

IAE says its new and improved system now features seven rail panels standing around the holding pens; this is to accommodate a wide range of cattle breeds, ages and sizes.

Labour cost reduction: By implementing a fixed cattle handling system, labour costs are significantly reduced. The system’s design plays to the strengths of natural cattle behaviour, making it easier for the handler to work the animals. With fewer workers needed for these operations, you can allocate your labour resources to other essential farm tasks, ultimately saving time and money.

To create an environment that ensures the handler’s safety is prioritised, a safe working zone runs down the centre of the system and can be fronted by a safety gate to prevent the ingress of cattle. Handlers can see and work all aspects of the system from the zone and narrow personnel gaps allow quick entry and exit to the holding pens. For visibility of cattle in the race, IAE’s new drop down platform provides a safe method of viewing the cattle.

Ease of handling: A fixed cattle handling system provides consistency and ease of handling for both the animals and the handlers. With well-defined and easily navigable races and pens, cattle can be quickly and safely moved from one area to another. This reduces the risk of injuries to both the animals and the handlers, making the entire process more efficient and less stressful for everyone involved.

Cost-effectiveness and long-term value

When considering the cost-effectiveness and long-term value of a fixed cattle handling system, it is crucial to evaluate the pros and cons. While the initial investment may seem daunting, the potential benefits of increased productivity, improved animal welfare, reduced labour costs, and ease of handling cannot be ignored.

IAE’s new and improved fixed cattle handling system is currently eligible under FETF57. For more information about its fixed cattle handling system and the variations it can offer, visit the IAE website or contact the sales team directly.

View FarmAds livestock equipment for sale

Graham runs three John Deere 6150Rs for mowing, raking and hauling silage at Chelker House Farm in Addingham, west Yorkshire, with the trio of tractors between eight and nine years old. Graham is a third-generation farmer and runs the business in partnership with his father, Max, while his son, Sam, plays a key role in both the dairy and contracting operations.

Although the size of the tractors was akin to Graham’s previous machines, the tractors were significantly underpowered and rated at 136hp. Output losses when running the twin mowers and hauling silage on the hilly terrain were most notable.

“Output with the mowers in a good silage crop was around 7kph, but the biggest problem was when the front mower hit some already cut grass at the end of a row, the tractor just died and had nothing left to give, forcing the operator to lift or slow to crawl.”

The tailored ECU remap from Avon Tuning HD was installed by local service engineer, Tom Eckton, and along with carrying out the remap, he provides advice over the phone when required.

“We have only increased the tractor power to within the safe limits of the engine and drivetrain, as reliability is still key,” says Graham. “We have a lot of investment tied up in these machines, so we want to keep them in top condition. The tractor can now handle the mowers at 15kph comfortably and keep running to the end of the row even in the thickest crops. It means we can drop more grass per day which the forager can easily clear.”

Since the remap, the tractors aren’t using any extra fuel to counteract the increases in work efficiencies. “Any fuel use increase is offset by greater output when mowing and hauling trailers. Alongside this, the wider implications of running an underpowered tractor that can slow the forager down, is a big factor.”

Remapping has allowed Graham to run cost-effective tractors in his business, while improving power outputs to match the demand of his implements and increase work efficiencies not only from the tractors, but the wider harvesting process.

View FarmAds forage and silage equipment for sale

Suffolk Plant Machinery Ltd has been awarded the Faresin telehandler range from Italy, offering professional machines for the agricultural, livestock, energy, straw, construction, commercial and industrial sectors from 2.6–6.5-tonne lift capacity with 6–17m lift heights.

Available ranges are:

Small: For facilities and work environments with limited space. Cab height: 1,935mm, width: 1,890mm, lifting capacity: 2.6t, lifting height: 6m.

FS Compact: High-level performance with great agility in tight spaces and unique visibility. Spacious and ergonomic cabin available in the lowered 2,250mm version. Lifting capacity: 3.2t, lifting height 7m with a unique 9m version.

FS Middle: A ductile machine offering management savings and high performance. Lifting capacity: 3.5–4.5t, lifting height: 7–10m.

Heavy Duty: High handling capabilities without compromising performance. Lifting capacity: 6–7t, lifting height 9–10m.

Big: Best choice for material handling operations in construction areas. Lifting capacity: 4–4.5t, 14–17m lifting height.

Full Electric: Includes models with boom lengths from 6–17m and lifting capacities from 2.6–4.5t.

The full range offers 39 options on model size and engines with many options for building a machine to your specific requirements.

The Italian factory, now in its 50th year, has over 400 employees. Suffolk Plant Machinery, based in Brundish, also covers East Anglia as main dealer for Sunward excavators, skid-steer loaders and access platforms alongside a growing range of StarTrac compact tractors. It also offers hire machines, servicing, parts and fabricating services.

View FarmAds materials handlers for sale

Tristan Dale of Dales Agri alongside the Maschio Gaspardo Chrono 508 Precision Drill.

Dales Agri is an agricultural contractor based near Macclesfield, covering the surrounding counties. The business has been providing agricultural services for over 35 years and was established by Anthony Dale, who now runs the business alongside his son Tristan.

Anthony and Tristan describe themselves as providing the full dairy industry service, from grass harvesting and baling (round and square bales), to ploughing and cultivating, all aspects of slurry, plus arable services including, combining and drilling.

Covering Cheshire, Staffordshire, Berkshire, Derbyshire and Norfolk, during the busiest times of the year they have a 25-strong team consisting of self-employed and sub-contractors, who ensure the Dales team can provide a full agri-service to their customers.

The Dales Agri team have been operating Maschio Gaspardo machines for a number of years; including ploughs, drills and a power harrow, before deciding to purchase a Chrono 508 high speed precision drill in 2021 from the Cornthwaites Group.

Set apart from the rest

Maschio Gaspardo product specialist & territory manager, Mac Simpson, says: “The Maschio Gaspardo Chrono 500 is a mounted drill which has a key feature that sets it apart from the rest. It can be set up to run with variable row spacings and is equipped with either eight or 12 planting units, making it suitable for sowing a range of crops with 45, 50, 70 or 75cm row spacings. This versatility makes it possible for the operator to switch from drilling sugar beet in the morning to maize in the afternoon, the conversion taking less than two hours.”

Anthony Dale comments: “When we first bought the drill we had a few initial teething problems; however, the back-up and support that we received from Maschio was excellent and problems were sorted really quickly.”

The decision to purchase the Chrono, was very much based on the speed, accuracy and ability to vary the row spacing, Anthony continues. “Before buying the Chrono 500, we were running two Gaspardo drills, a Mirka 8-row at 75cm and a Magica 8-row variable 45–80cm – but we wanted a machine that could cope with both fodder beet and maize and at the speed and accuracy we need to provide for our customers, which led us to the Chrono 500.”

Having built such a good relationship with Maschio Gaspardo, the Dales Agri team continues to test the products today. “We eventually became an unofficial tester as we kept pushing the machinery to the limits,” explains Anthony.

This year, they have drilled 80% of their maize at 50cm spacing with tramlines and are looking forward to seeing the results.

Tristan Dale says: “Although the Chrono can also be used for other small seed crops, such as OSR, we are currently using it for maize and fodder beet as these are very much the needs of our customers and the areas we cover.

“Due to the speed and the accuracy of the Chrono 500, we are able to drill on average 100–120 acres a day working at a rate of between 12–18kph, which is great compared to other drills available. We have had other drills in the past, but that aren’t as easy to swap out the rows and we really like that you can vary the pressure too.”

Anthony adds: “When drilling sugar beet, you need to drop the downward pressure because you need to be careful as the higher pressure can blow the seed out of the slot.

“And so, the accuracy and speed were the deciding factors for choosing the Chrono.”

Keeping ahead of the drill

One area that the team have found challenging is ensuring they keep ahead of the Maschio Gaspardo Chrono 500, as the speed means they need to have the ground ready to go sooner than previously required.

“The weather can be a real challenge for ensuring we keep well enough ahead for the drill. Due to the speed the drill can work at, if we’ve had too much rain it can make it difficult to ensure we have worked the land in time ready for the drill to pass, because as we know, that can also cause its own problems, such as compaction and soil structure damage,” explains Anthony.

The Dales Agri team also run a Maschio Gaspardo 8m Jumbo Power Harrow, that is used to stay ahead of the drill. The Jumbo is an ultra-heavy-duty power harrow suitable for extremely hard stony soil, due to its specially developed barrel style double taper roller bearing.

Mac Simpson points out: “The Chrono is also fully Isobus-compatible enabling all its functions and adjustments to be handled either through an existing tractor terminal or an additional Isobus controller. In combination with the electronically-driven seeding units and microgranular applicator, the GPS-compatible drill controller also provides automatic row shut-off/section control and the potential for variable rate seeding and fertiliser applications.”

Great investment

Both Anthony and Tristan agree the Chrono 500 has been a great investment for their business. “The Chrono 500 comes as a full package and so all the optional extras are included meaning we have the flexibility and convenience of the function adjustments from the tractor cab.

“The accuracy of the drill at such high speeds combined with the ability to change rows quickly has made a real difference to the business, meaning we only need to run one drill not two,” concludes Anthony.

If you would like to learn more about the Chrono 500 series contact your local Maschio Gaspardo dealer, or visit the Maschio Gaspardo website

For more information on Dales Agri visit the website

View FarmAds seed drill equipment for sale

As with all the Awemak products offered by PFC, there is no compromise on build strength and quality, the company says. The 3m setup with high or low disturbance leg options on the Sherp are protected by sprung auto reset. The standard hydraulic three-point linkage couples directly to the Ozyrus Discs with minimal down time to sperate and connect as required. Using hydraulic linkage allows ultimate precision adjustment to the depth control of both the Sherp disturbance legs and the 3m discs.

The Ozyrus discs have as standard, two rows of 12 discs with 560mm diameter, active side screens, deflector board between the row of discs, straw tines, hydraulic depth control, led lights and steel ring packer. There are various rear rollers and packers available with the option of doubling up to have a twin roller or packer.

The Sherp and Ozyrus combination is designed to provide effortless working efficiency as the operator can adjust on the go the working depth of the two components to suit ground conditions and soil types. Having the ability to separate the two components allows for more varied jobs to be carried out.

Chitting grain after harvest is the main consideration, and utilising the discs to work the top 1cm then reconnecting before drilling to work the ground allows the operator to create an ideal seed bed. On the PFC test farm, min-till has been used successful to replace the plough, reduce establishment cost and improve time management of the continuous wheat crop.

View FarmAds tillage equipment for sale

The company is based just outside the small village of Markethill in Northern Ireland.

Following the company’s formation in 2013, founders Mark and Dean Belford say they are proud to have been leading the business into rapid yearly growth.

“As children we made our own toys to play with in the garden. Our dreams were that someday we would own a factory making toys for other children,” commented Mark.

“As the years progressed, so did our enthusiasm for engineering. We have never seen engineering as a job or career – it’s our passion!”

MDE Machinery makes tree shears, silage forks, and buckets for forestry and agricultural industries. The company’s attachments are designed for excavators, wheeled loaders, telehandlers, and tractors, and specifically designed and engineered to efficiently handle a wide range of material.

According to Dean, MDE’s vision and dream now is to become a global manufacturer of both agricultural and forestry machinery attachments that customers can really put their trust in.

Proving how quickly the business has grown in a relatively short time, MDE’s products currently can be found in 24 different countries – including as far away in New Zealand.

Mark and Dean say they are always striving to push the MDE brand globally, and welcome any international dealers to be part of their team.

MDE works closely with its customers and agricultural machinery dealers to improve and discover new products. The company’s ethos is that, in order to design world market-leading equipment, it needs to take on board its customers’ opinions and ideas, and is constantly developing new products and ideas.

Two examples within the forage and silage portfolio of products include the MDE Rhino Pak silo compactor, which is designed to increase silo capacity, reduce feed loss/spoilage reduce silage slippage, and provide access to hard roll areas; and the heavy-duty Falcon pushoff buckrake, which features Hardox tines as part of a heavy-duty construction, designed for strength.

View FarmAds forage and silage equipment for sale